24

KS 1710010

Needle bearing 7941/15

1

KS 70-1710006

Ball bearing 306 (GB/T276-94)

1

25

KS 78-1710007

Ball bearing 307 (GB/T276-94)

1

KS 86-1710008

Ball bearing 308 (GB/T276-94)

1

KS 70-1704601

1

26

KS 78-1704602

Crankcase cover gasket

1

KS 86-1704603

1

KS 70-1710002

Bearing 205 (GB/T276-94)

1

27

KS 78-1710003

Bearing 206 (GB/T276-94)

1

KS 86-1710004

Bearing 207 (GB/T276-94)

1

28

KS 1711111

Retaining pin 8x12 (GB119-86)

2

29

KS 78/86-17080

Fuel Pipe

1

KS 70-1701901

1

30

KS 78-1701902

Crankcase cover

1

KS 86-1701904

1

31

KS 17133

Inner Hexagon Plug G1/8

1

KS 70-1710083

M8 x 33.5 Bolt

1

KS 70-1711062

M6 x 25

14

32

KS 78-1710083

M8 x 33.5 Bolt

15

KS 86-1710083

M8 x 33.5 Bolt

16

KS 70-1711701

Front oil seal 25 x 42 x 10

1

33

KS 78-1711703

Front oil seal 30x 45 x 10

1

KS 86-1711705

Front oil seal 35 x 50 x 10

1

KS 70-1701801

1

35

KS 78-1701802

Main Bushing

1

KS 86-1701803

1

36

KS 78-1701903

Front side crankcase cover

1

37

KS 78-1711703

Front side oil seal

1

38

KS 70-1711602

Aluminum Plug Diameter 8 x 8

2

KS 78/86-1711602

3

Note:

If purchasing the engine cylinder block, the included parts are numbers 1, 2, 8, 9, 10, 12,

13, 14, 15, 16, 18 and 24. The parts of the crankcase cover include numbers 14, 18, 27, 28, 29,

30, 31, 35 and 38.

31

Summary of Contents for 170F

Page 1: ...OWNER S MANUAL AIR COOLED DIESEL ENGINE 170F FE FS FSE 178F FE FS FSE 186F FE FS FSE 1 ...

Page 12: ...1 2 Diesel Engine shaft specifications units mm 12 ...

Page 13: ...Sizes of PTO flanges Diesel Engine Power Curves 1 4 Names of Diesel Engine Parts 13 ...

Page 20: ...20 ...

Page 26: ...26 ...

Page 29: ...CHAPTER 4 PART LISTINGS Diesel Engine Exploded View 29 ...

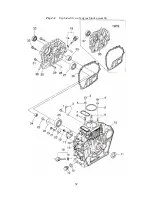

Page 32: ...Fig 4 1 Exploded view of engine block assembly 32 ...

Page 35: ...Fig 4 2 Exploded view of cylinder head 35 ...

Page 38: ...Fig 4 3 Exploded view of Piston Crank Assembly 38 ...

Page 40: ...Fig 4 4 Exploded view of fuel tank parts 40 ...

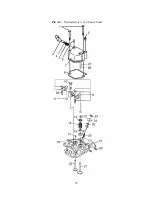

Page 43: ...Fig 4 5 Lubrication and speed control system 43 ...

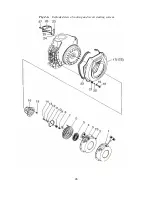

Page 46: ...Fig 4 6 Exploded view of cooling and recoil starting system 46 ...

Page 49: ...49 ...

Page 52: ...OWNER S MANUAL Air cooled diesel engine generator set DG4LE DG6LE 1 ...

Page 60: ...9 ...

Page 61: ...10 ...

Page 71: ...20 ...

Page 80: ...29 Figure 5 3 Exploded view of frame assembly ...