Rectifying problems

27

10 Rectifying problems

WARNING!

Troubleshooting may be performed by specialist

personnel with the corresponding qualifications

only.

If you troubleshoot without corresponding specialist

training and above all without the required experience,

safe operation is no longer guaranteed. The resulting

defects and consequential damage are excluded from

the guarantee and warranty.

Likewise, improper implementation can lead to serious

injuries.

DANGER!

Switch off the precipitator power supply

prior to troubleshooting

Before troubleshooting on the precipitator, the power

supply must be switched off.

Switch off the electricity to the boiler via the mains

switch prior to troubleshooting. This also switches

off the power supply to the precipitator.

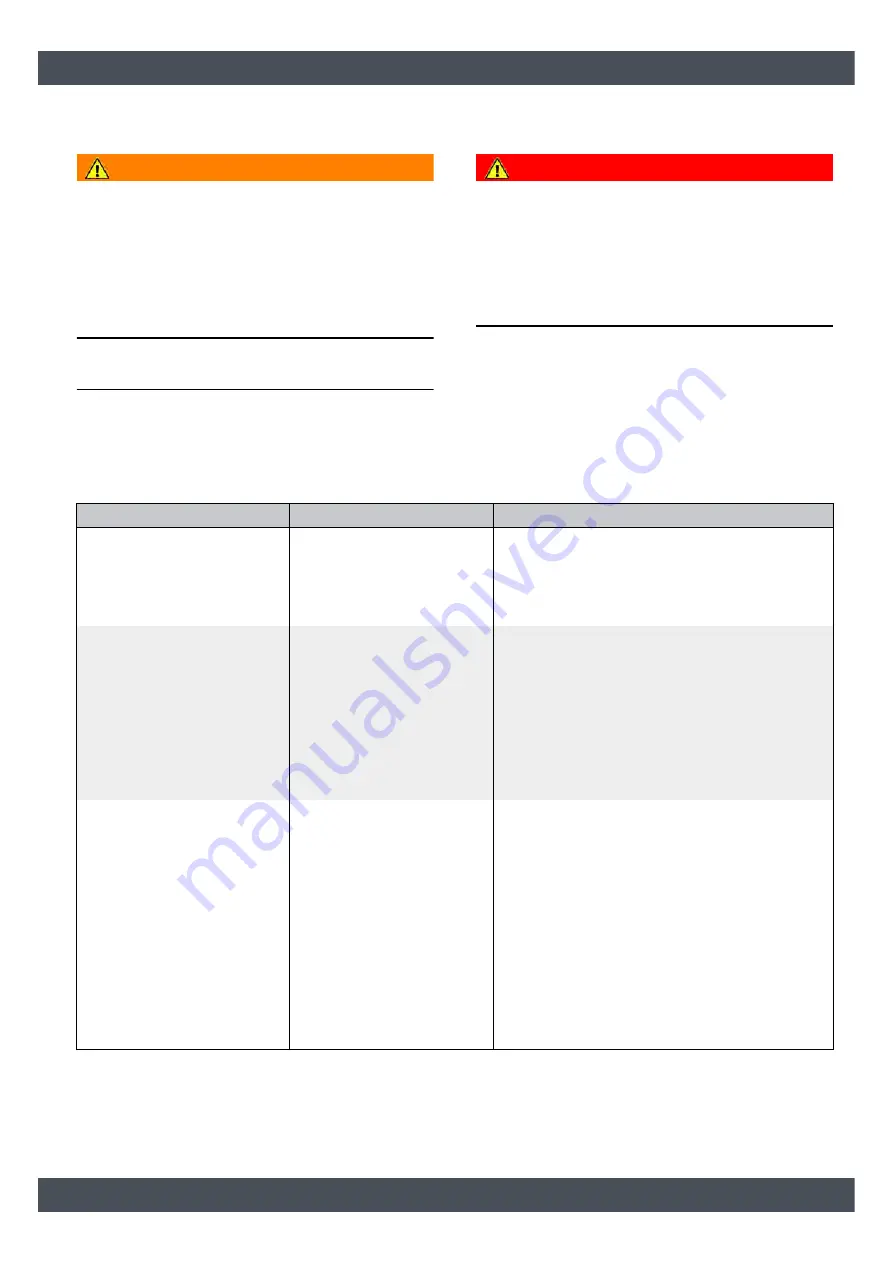

Possible precipitator malfunctions

Precipitator malfunctions are displayed on the screen on the boiler via the ETAtouch control system. Not all precip-

itator malfunctions also end the boiler heating mode. If the high voltage unit fails, for example, a message is

displayed, but the boiler heating mode continues to run. The flue gas is not cleaned as a result, however.

Error

Cause

Solution

High voltage: interruption

The connection between the

high voltage unit and the

electrode is interrupted.

•

Inspect the connection line between the

high voltage unit and the electrode for damage

and replace if necessary.

•

Inspect the power supply (230 V) from the

boiler to the precipitator.

High voltage: short circuit

The connection between the

high voltage unit and the

electrode is short-circuited.

Eventually a direct

connection between the

discharge electrode and the

inside of the precipitator is es-

tablished.

•

Check the electrode dedusting. The "striking

weight" may not be in the idle position (up) and

touching the electrode.

•

Inspect whether a connection is present (e.g:

as a result of adhering dust) between the

electrode and precipitator and remove it.

•

Inspect the connection line between the

high voltage unit and the electrode for damage

and replace if necessary.

Low degree of separation -

overvoltage too low

The electrode no longer has

sufficient high voltage.

Eventually a direct

connection between the

discharge electrode and the

inside of the precipitator is es-

tablished.

The isolator is

badly contaminated or

defective.

•

Check the electrode dedusting. The "striking

weight" may not be in the idle position (up) and

touching the electrode.

•

Inspect whether a connection is present (e.g:

as a result of adhering dust) between the

electrode and precipitator and remove it.

•

Inspect the connection line between the

high voltage unit and the electrode for damage

and replace if necessary.

•

Inspect the isolator for impurities or damage.

Also clean out the opening between the

isolator and electrode holder with a vacuum

cleaner.

Summary of Contents for EEP 130

Page 30: ...www eta co at ...

Page 31: ......

Page 32: ...www eta co at www eta co at downloads DOWNLOAD ...