Rectifying problems

35

8

Rectifying problems

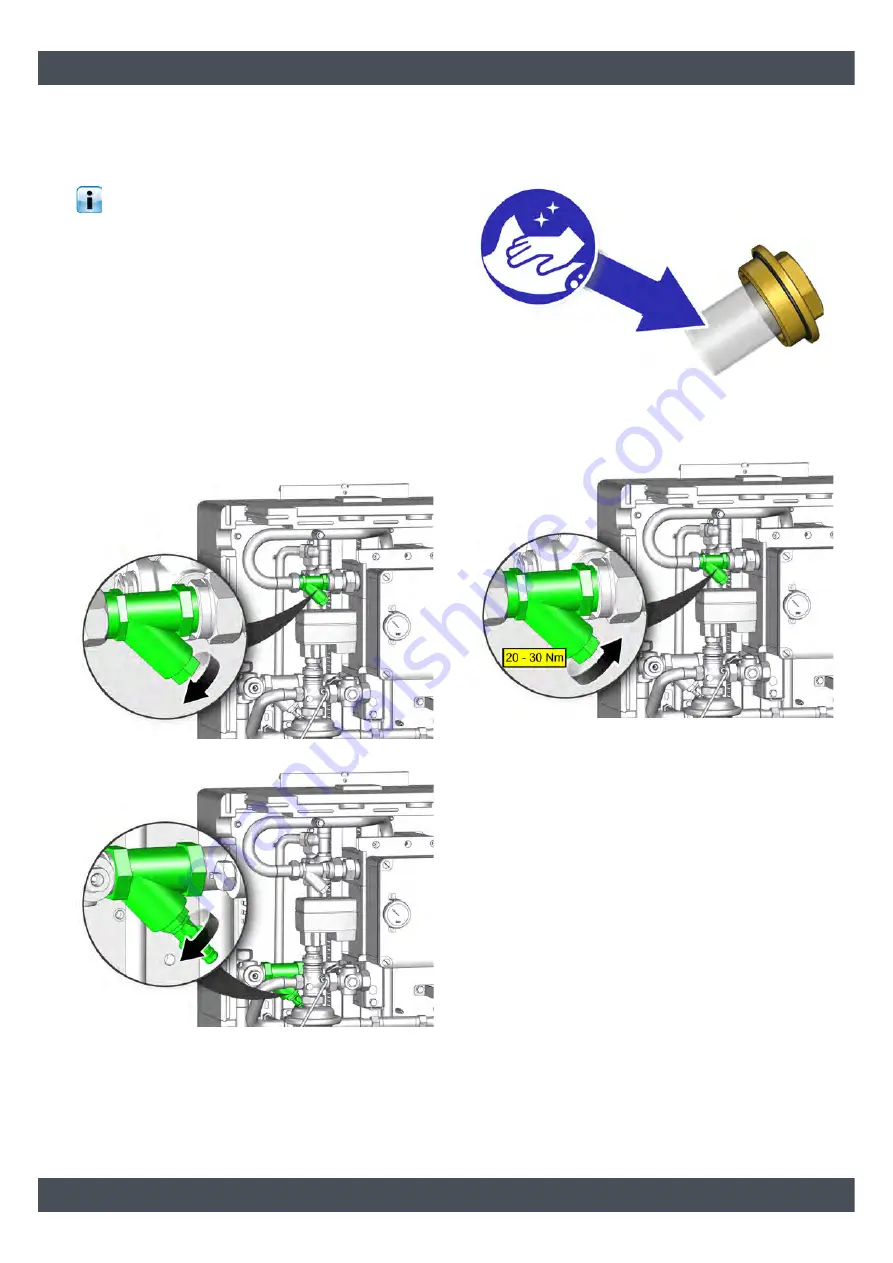

Cleaning the strainer

If the performance of the heat transfer station

decreases during operation, often the strainer is

dirty. Therefore, clean the strainer first before carrying

out other measures.

The strainers are located on the primary and

secondary side. The following describes the cleaning

of the strainer on the primary side. This applies

accordingly to the secondary side.

1. Close the ball valves for flow and return of the

primary and secondary side in order to limit wa-

ter leakage.

2. Carefully remove the front panel.

3. Remove the cap on the strainer and catch the

escaping water with a towel. Hot water may leak

out.

Fig. 8-1: Strainer on the primary side

Fig. 8-2: Strainer on the secondary side

4. Clean the strainer and then reinsert it.

Fig. 8-3: Strainer

5. Fit the sealing cap and tighten it with a maximum

of 20-30 Nm. Do not use pipe wrenches for

tightening.

6. Reopen the flow and return ball valves.