Change Decoder Settings

Functions / Identification / CVs

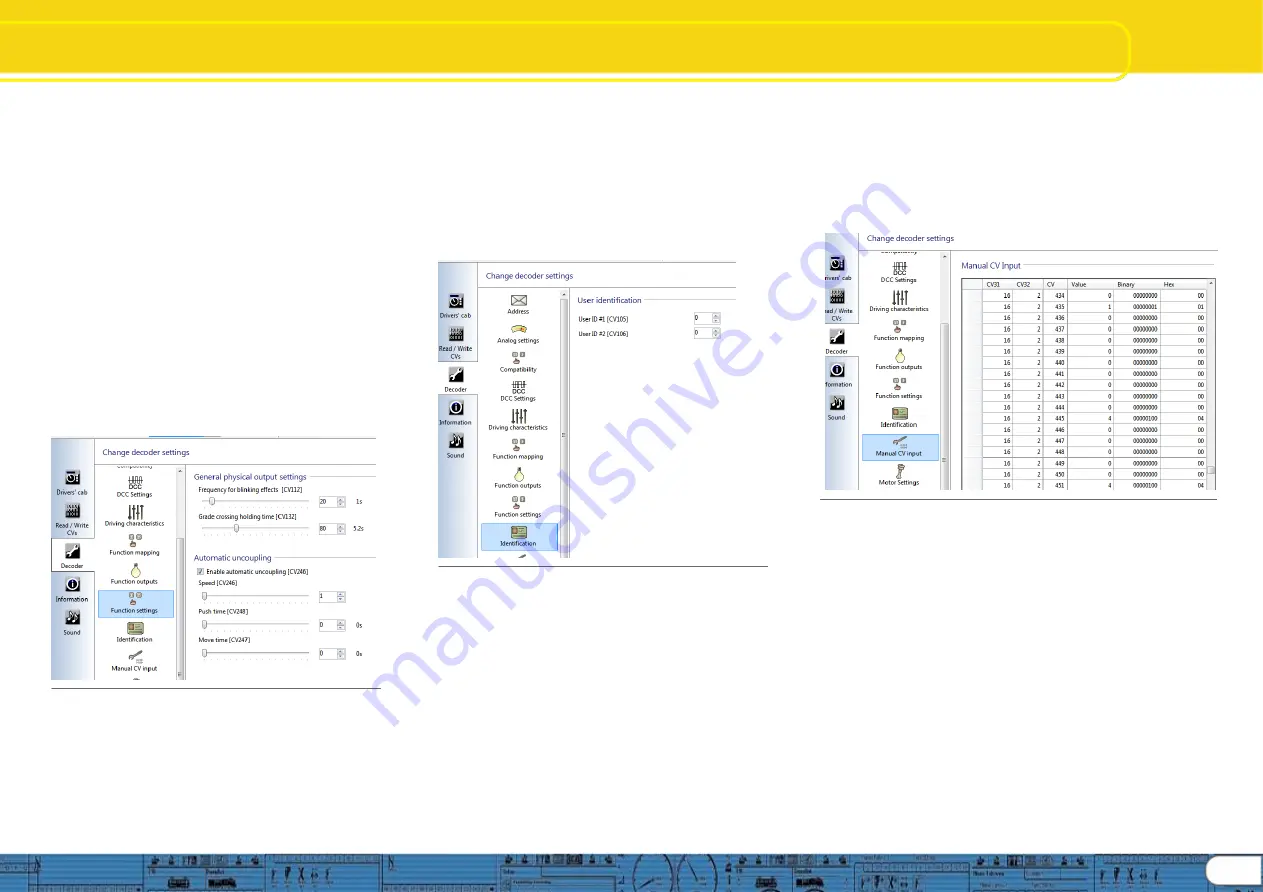

8.6.6 Function settings, “General” and “Automatic uncoupling”

As mentioned in 8.6.5 above, when mapping logical

functions to a function key, in some cases you should also

use Function settings in order to enable the response you

desire when the function key is engaged. General settings

are for configuring lighting effects, and allow you to set the

blink frequency for lighting situations that require blinking

lights (CV112), and for setting grade crossing holding time

(CV132). Holding time is the amount of time the grade

crossing effect is enabled.

Automatic uncoupling is where automatic uncoupling is

enabled (CV246), and where you can set the uncoupling

speed across a range of 1

– 255 (same as the speed table

range), default is 1 (CV246). Push time (CV248) is the time

in seconds the automatic push is in effect; and Move time

(CV247) is the time in seconds the locomotive moves away

from the uncoupled car(s). Of course “time” relates directly to

distance traveled at the speed set for the duration of the

automatic uncoupling cycle. See figure 37.

Fig. 37.: Configure Function settings

8.7. Identification

8

.7.1 Data fields, “User identification”

The user identification fields are open fields that can be used for any

purpose. These are designated as “User ID #1” and “User ID #2”.

CV’s are CV105 and CV106 respectively. Value range for both is 0 –

255 and they can be set individ

ually or together. Setting these CV’s

does not change any decoder behavior, they are an open code

section and can be used for any purpose, perhaps to track a certain

version, or function key structure. Default value is 0 for both CV’s.

See figure 38

Fig. 38.: User Identification

8.8. Manual CV Input

8.8.1 Manual CV Input

This section of the change decoder data screens is made available

should you wish to make manual CV changes without using the

preformatted decoder set up screens and views. It is also very useful

for researching CV’s. When you export the decoder CV listing (See

“5.3 Tools”, Export CV list) the text file that is created during the export

will consist of the same data displayed in this view.

8.8.2 CV changes

CV changes can be made directly by overwriting the data in any of

the data fields; “Value”, “Binary”, or “Hex”, simply enter the value you

wish and then tab out of the field and the data will be changed and the

other two data columns will update. Of course it is much easier to

enter direct numeric data in the “Value” column than it is to write

Binary or Hex data.

After you are finished making changes, the new values may be

written to the decoder using “Write decoder data” (See “5.2

Programmer

”, Figure 12)

Note: The ability to make manual changes is very powerful and

should be used with care. Consider saving the changed project

file under a new name in order to provide a way to rewrite last

known good data to the decoder to recover from mistakes. See

figure 39.

Fig. 39.: Manual CV Input

8.9. Motor Settings

Here is where you configure speed table, load control, PWM

frequency, and overload protection settings on the v4 decoder

series. Information presented here deals directly with making

desired settings using the LokProgrammer tool to configure the

decoder, therefore the level of detail presented is not at the same

level as is found in the v4 decoder manual. Please use the

detailed information found in the decoder manual, chapter 10, as

the preferred source for decoder information.

8.9.1 Speed table selection and configuration

(CV 2, CV

5, CV 6, CV 26, and CV 67-97)

Here you may select either a 3 point speed table (figure 40) or a

custom speed curve (figure 41). If you use the 3 point table you

should set minimum and maximum speed (CV2 and CV5) and

then pick the mid range speed (CV 6) as desired. You may also

use the slider on the right hand side to set both maximum and

mid range speeds. In order to avoid possible rough or unusual

running, please ensure

17