14

Change Decoder Settings

Driving Characteristics / Functions

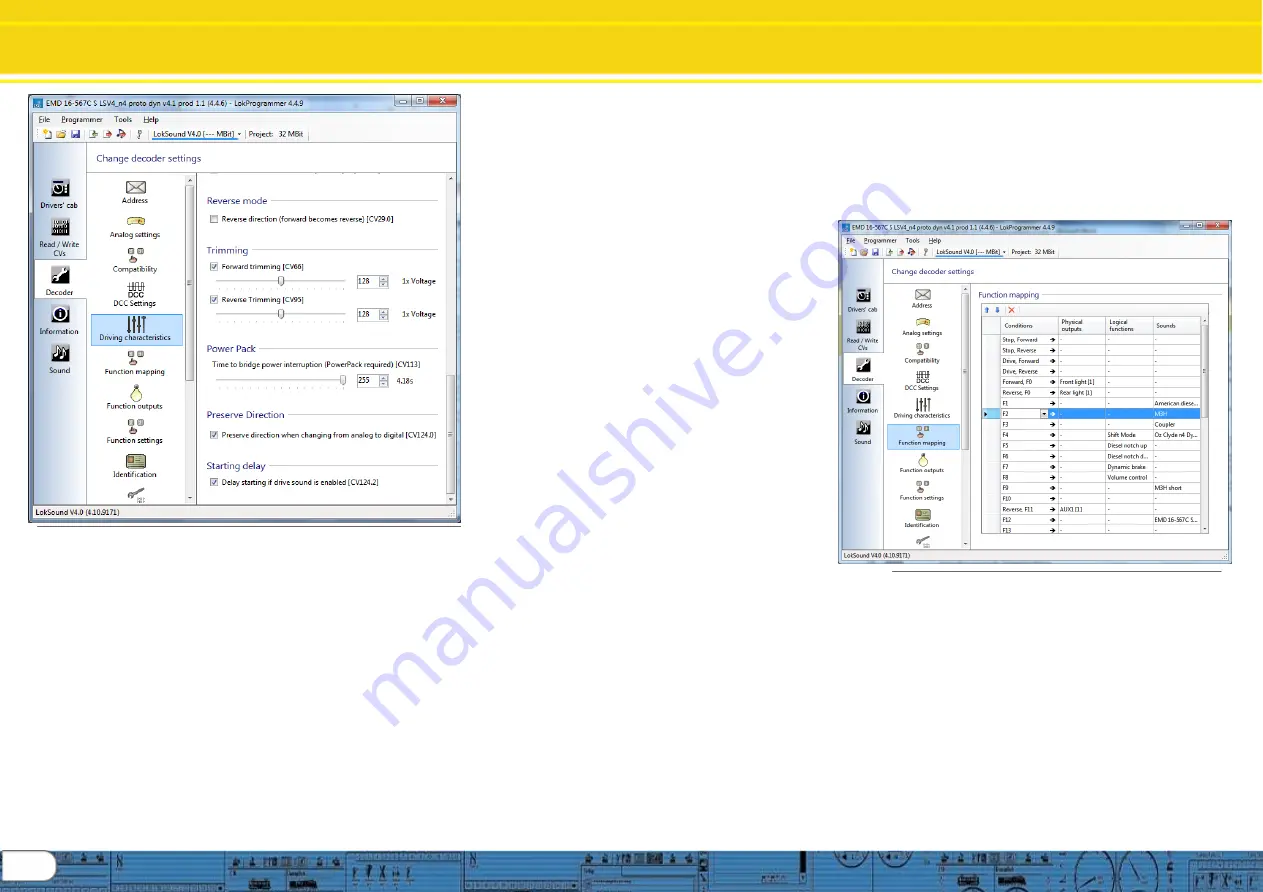

Fig. 26.: The „Driving characteristics“ register

8.5.4. Reverse mode (CV 29)

A tick at „Reverse mode“ changes the direction of travel

and the directional characteristics of the headlights. This is

useful in case the wiring has been done incorrectly

(swapping of track

leads or motor leads).

8.5.6 Trimming (CV66, CV95)

The trim function allows you to set the maximum speed

separately for forward and reverse movement. The factor

that is used to multiply the motor voltage, results from

dividing the CV-value by 128 (forward CV 66 and reverse

CV 95).

8.5.7 Power Pack (CV 113)

V4 decoders (HO and N) provide for the installation of capacitors

or power packs (so called “keep alive” devices). CV113 allows

control of the amount of time the device is active. Setting range is

0 to 255 via the adjustment slider; an estimated active time is

shown to the right of the setting in seconds. Information for

installing capacitors or power packs can be found in the decoder

manual chapters 10.9 (configuring) and 6.11 (wiring).

8.5.8 Preserve Direction (CV124.0)

Checking this option keeps the direction constant when the v4

equipped loco transitions from DCC control to Analog controlled

track sections.

8.5.9 Starting delay (CV124.2)

Usually, when the LokSound V4.0 sound is idling and you turn up

the throttle, the locomotive begins to move only after the Diesel

engine has reached notch 1. A steam loco will even release its

brakes first and fill the cylinders. Although this behavior is very

prototypical, one might not like it because it causes some delay.

You can control this startup delay by simply not checking this

option. This will cause the LokSound V4.0 decoder to immediately

start moving when the throttle is turned up. However, the start up

sound will not be synchronized with the motion anymore.

8.6. Function views

Both LokSound V4.0 and LokSound micro V4.0 decoders have

identical function mapping. M4 and XL decoders have different

screen displays. The display will shift when the decoder type for

any given project is changed; therefore, the screen display

depends on decoder type. Shown here is the display for V4

standard and micro decoders. A great deal of information is

available in the v4 decoder manual concerning function mapping.

Of course, which sound is assigned to which sound slot may vary

depending on the decoder project. You will find a list with all

available project files “Download/Sound files/LokSoundV4.0/“ on

our home page at www.esu.eu. You may also view and print a list

with all functions and the sound slots employed.

The LokSound V4.0 decoder offers powerful and flexible function

mapping options:. Each function button can switch as many

outputs as desired. Each output can be activated by several

function buttons. Function buttons can be linked (e.g.: F3 AND F5

pressed simultaneously)

Function buttons can be inverted (e.g.: NOT when F8 is on).

Besides the buttons F0 to F28 you can also incorporate the

direction of travel or the speed (locomotive is moving / has

stopped)

You may connect as many as 5 external sensors. While

many model train enthusiasts need precisely these functions

for optimal running of all their locomotives setting up

function mapping represents so to speak the “free style”

version of decoder programming. Take your time to

understand the concept behind it before you start changing

any settings. For a complete review of all function mapping

CV’s, see the v4 decoder manual.

HINT: Even if you do not have LokProgrammer hardware,

you can still use the software as an aid in making mapping

changes in conjunction

with the “Show changed CV’s”

capability.

Fig. 27.: The „Function mapping“ register

The function mapping view is arranged as a matrix with

vertical columns for conditions, physical outputs, logical

functions and sounds. Horizontal rows list each condition

and function key for use in mapping as desired. See figure

27.

8.6.1 Function mapping,

“Conditions”

The input block (conditions block) shows which condition is

required to achieve a certain output. Conditions are for

instance “F3 On” or “Locomotive is stationary with direction

set to forward, and F8 is switched on”. Configuring the

outputs to behave as desired begins by deciding which

function or function key you wish to configure to enable an

output that will perform the desired action when the function

is on, or off.