34

Cleaning of platen roller (indication of cleaning: after the operation is terminated)

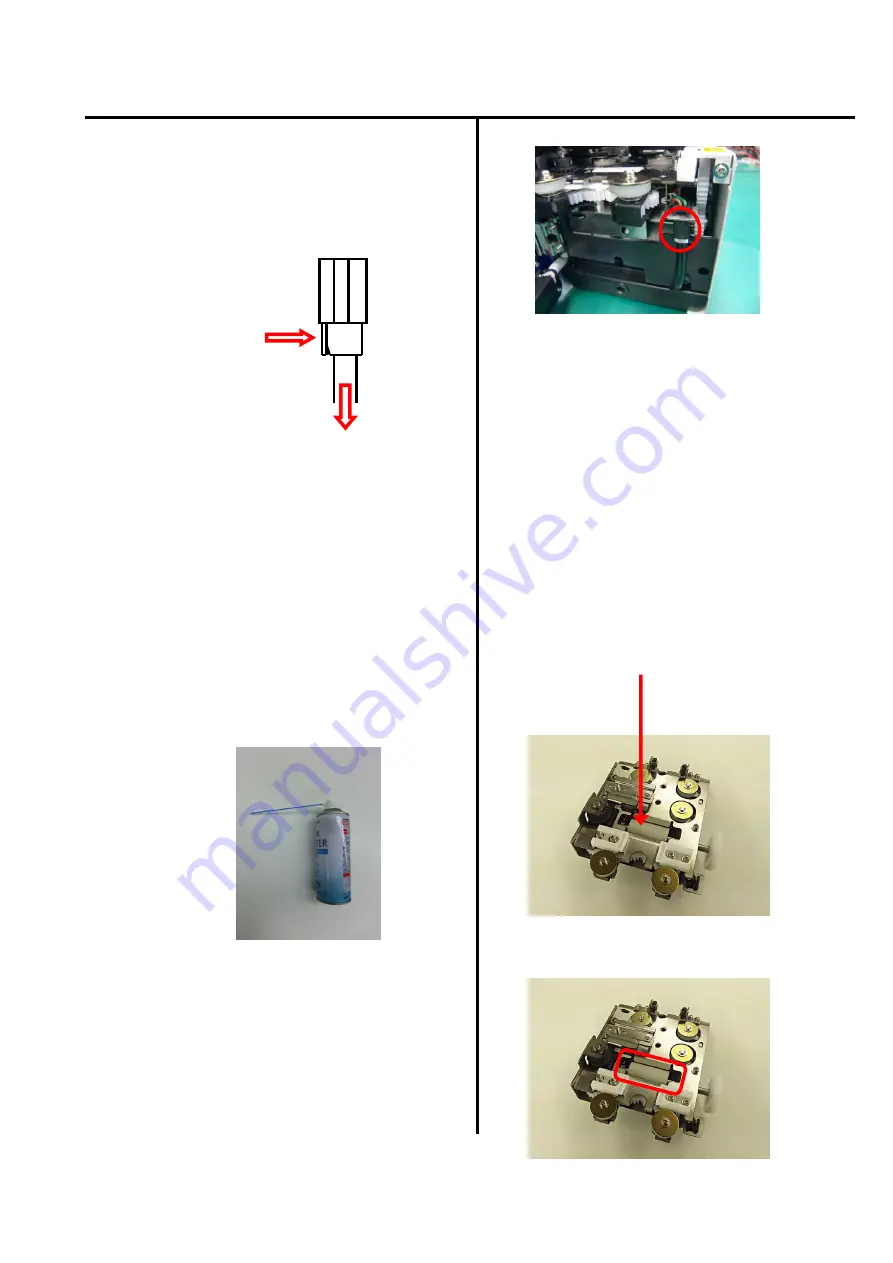

Open upper cover and front cover.

Disconnect the connector and pull out the

transfer unit.

(1)

(2)

While the lock nail is pushed toward (1), pull

out the connector downward (2).

Remove the taint attached to the platen roller

using an air blow etc.

Clean up the whole circumference of platen

roller while rotating it.

Air blow

Clean up the platen roller using a waste

cloth impregnated with dehydrated ethanol.

Clean up the whole circumference of platen roller

while rotating it.

Platen roller