© ESAB AB 2011

- 12 -

bc23de

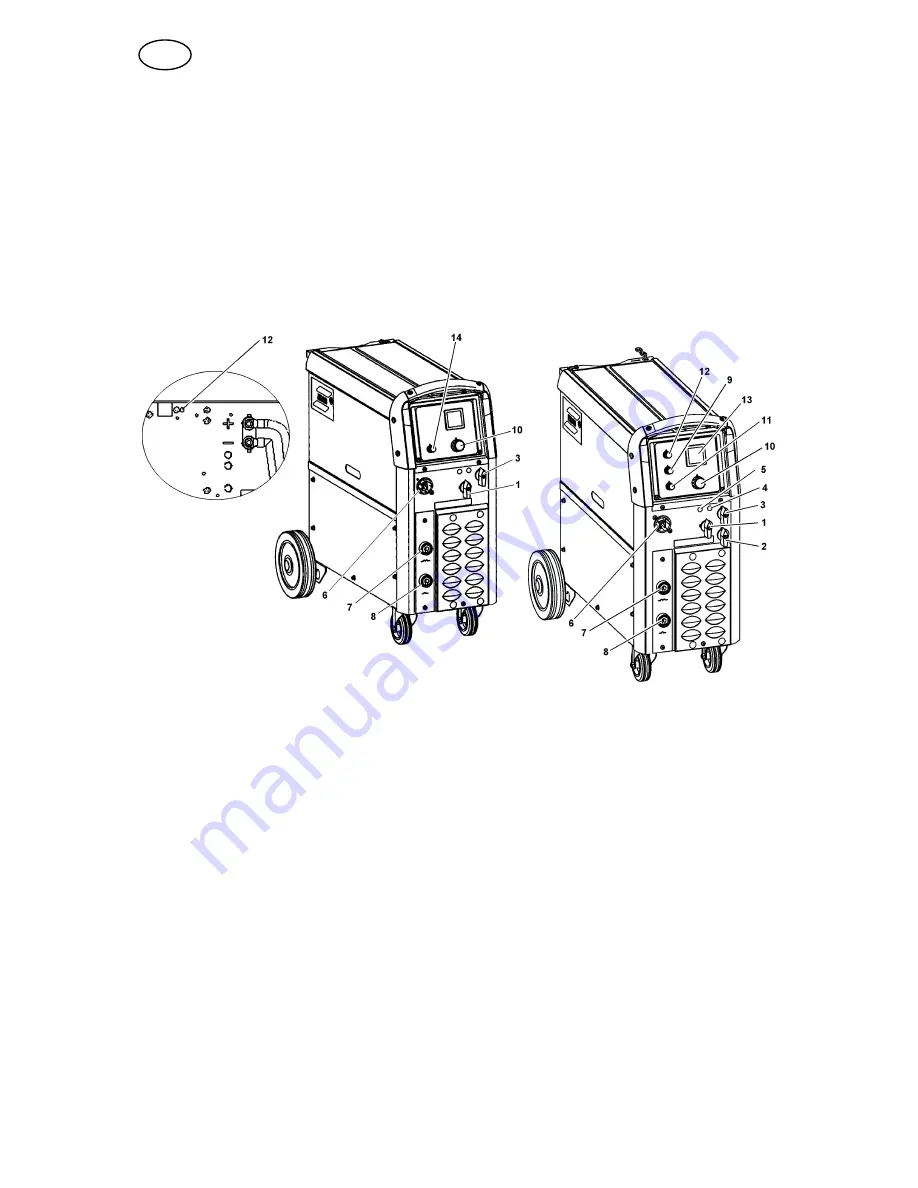

5.1

Connection and control devices

1

Mains supply switch

8

Connection for return cable (-), low

inductance

2

Switch, coarse control

9

Knob for selecting - creep start - ON/OFF

3

Switch, precise control

10

Knob for wire speed setting

4

Indicating lamp, power supply ON

11

Knob for selecting 2/4-stroke control mode

5

Orange indicator lamp, overheating

12

Knob for burn-back time setting

6

EURO - connector (for welding gun)

13

Digital instrument - V / A

7

Connection for return cable (-), high

inductance

14

Knob for spot welding - ON/OFF and time

setting

5.2

Overheating protection

A thermal overload cutout protects against overheating. The cutout resets automatically

when the unit has cooled.

5.3

Inductance connection

Higher inductance produces a more flowing weld and fewer spatters. Lower inductance

produces a harsher sound and a stable, concentrated arc.

GB

Summary of Contents for ORIGO Mig C280 PRO

Page 2: ... 2 ...

Page 16: ... ESAB AB 2011 Diagram 16 bc23e Mig C280 380 415V ...

Page 17: ... ESAB AB 2011 17 bc23e Mig C280 380 415V ...

Page 18: ... ESAB AB 2011 18 bc23e Mig C280 230 500V ...

Page 19: ... ESAB AB 2011 19 bc23e Mig C280 230 500V ...

Page 20: ... ESAB AB 2011 20 bc23e Mig C340 380 415V ...

Page 21: ... ESAB AB 2011 21 bc23e Mig C340 380 415V ...

Page 22: ... ESAB AB 2011 22 bc23e Mig C340 230 500V ...

Page 23: ... ESAB AB 2011 23 bc23e Mig C340 230 500V ...

Page 24: ... ESAB AB 2011 Connection instruction 24 bc23c 230V 380 415V 440 460V 500V ...

Page 30: ... 30 notes NOTES ...

Page 31: ... 31 notes NOTES ...