7

F.

FEEDING WIRE

1.

With MIG-41 Gun completely installed and all

power OFF, feed wire by hand through the feed

rolls of the wire feeder and guide the end of the

wire into the liner of the wire feeder connector as-

sembly. Then close the feed roll clamp.

2.

Pull the drive roll cap off gun and flip idler arm down.

Remove nozzle and contact tip from front end of

gun.

3.

Lay the gun and cable out straight and then inch

the wire through the cable. Inching can be accom-

plished from either the wire feeder or gun.

4.

When wire reaches the drive roll, make sure the

wire fits into the groove of the drive roll and is di-

rected into guide tube opening in the wire guide of

gun.

The drive roll components and wire are electrically

hot when gun trigger is depressed.

5.

When wire appears out of the front end of gun,

reassemble contact tip and nozzle. Close idler arm

and reinstall the drive roll cap .

Do not adjust the

pre-set tension in the cap knobs. Do not inch

the wire using the control inch button when

the wire is completely through the torch and

the idler arm closed. Birdnesting will occur at

the feeder.

IV. OPERATIONS

A. ADJUSTMENTS

1.

Before welding, ease tension on the wire feeder

feed rolls if necessary. (See appropriate wire feeder

instruction booklet.) They should not be tight

enough to shave the wire. Proper wire feeding re-

quires the pull motor of the gun and the push at

the wire feeder working together.

2.

Before welding, also be sure the torch gas system

has been thoroughly purged and the coolant sys-

tem has been completely filled.

Whenever welding above 250 amps, a No. 14 filter

lens should be worn on your protective helmet. Up

to 250 amps, use a No. 12 filter lens. Refer to page

2 of this booklet for additional operating precau-

tions.

CAUTION: Do not drop gun or remove spatter from

nozzle by hitting the front end against a

hard surface. This may damage the front

end and/or motor assembly. A damaged

front end can cause gas or coolant leak-

age.

V.

MAINTENANCE

If this equipment does not operate properly, stop

work immediately and investigate the cause of the

malfunction. Maintenance work must be performed

by an experienced person, and electrical work by

a trained electrician. Do not permit untrained per-

sons to inspect, clean, or repair this equipment.

Use only recommended genuine ESAB replace-

ments parts.

A. NOZZLES

Spatter can be removed from the inside of the nozzle

with a hand reamer or file. Adherence of spatter can

be minimized and removal made easier by coating the

inside of the nozzle with No. 65 Nozzle Anti-Spatter

Compound (4-oz. container - P/N 03N65; 1-qt. con-

tainer - P/N 08N75).

VI. REPLACEMENT PARTS

All replacement parts are keyed in Figs. 3, 4 and 5.

Order replacement parts by part number and part

name. Do not order by part number alone. Replace-

ment parts may be ordered from your welding prod-

ucts distributor or ESAB Welding & Cutting Systems,

Customer Service Dept., Florence, SC.

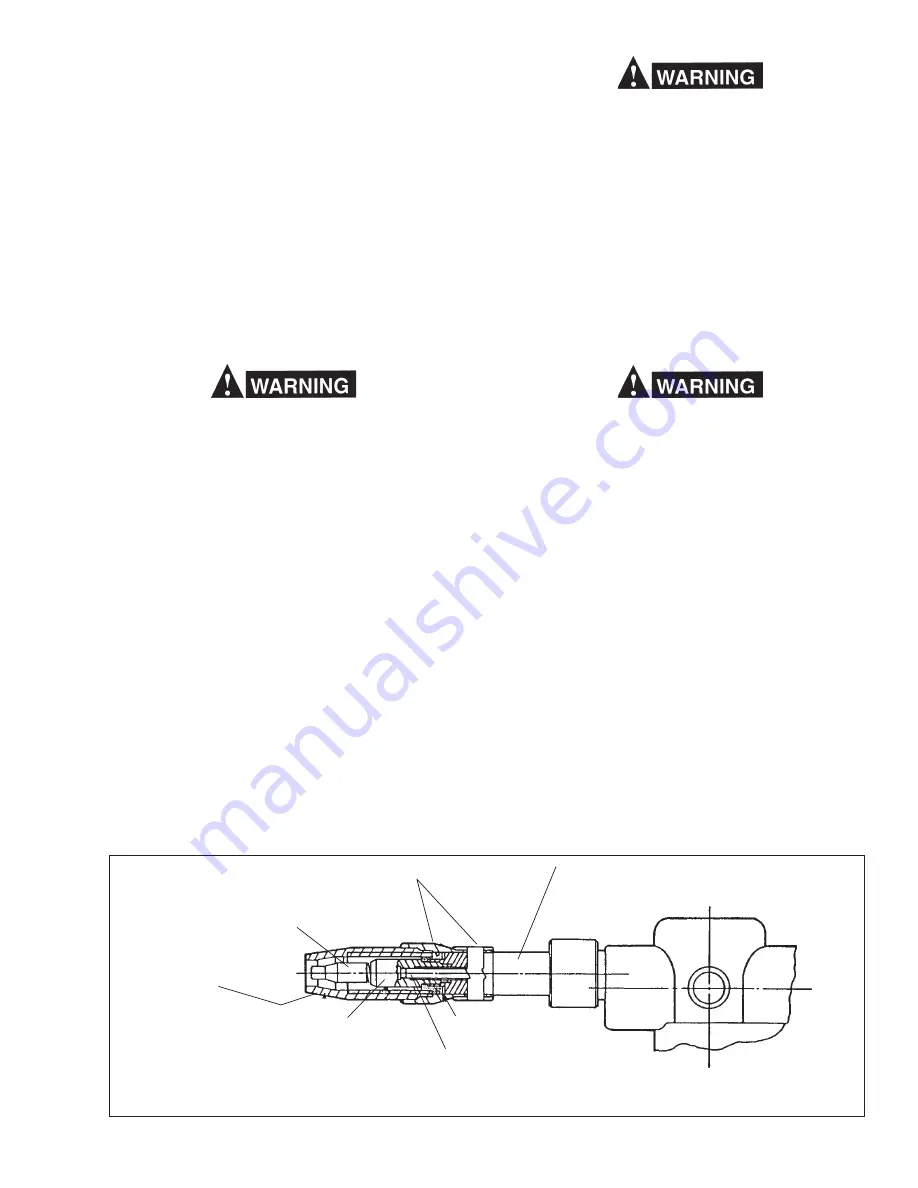

Fig. 3 - Replaceable Front End Parts

CONTACT TIP - See Table 3

NOZZLE - See Table 3

(No. 10 supplied with torch)

*TIP ADAPTOR - 18927

OPT. ACCY: 45° CURVED FRONT BODY - 19757

Requires: WIRE GUIDE - 19758

includes: LINER - 19759

FRONT BODY ASSY. - 19258

includes: NOZZLE BODY & CLAMP - 18930

INSULATOR ASSY. - 18924

INSULATOR ASSY. - 18924

(included w/19258)

WIRE GUIDE - 19991

LOCK NUT - 19264 (located in torch body

under drive roll cap)

NOZZLE BODY & CLAMP - 18930 *

(included w / 19258)

* Nozzle Body & Clamp replacement requires using Nozzle Body Replacement Tool Kit - 19092