7

7..1

1

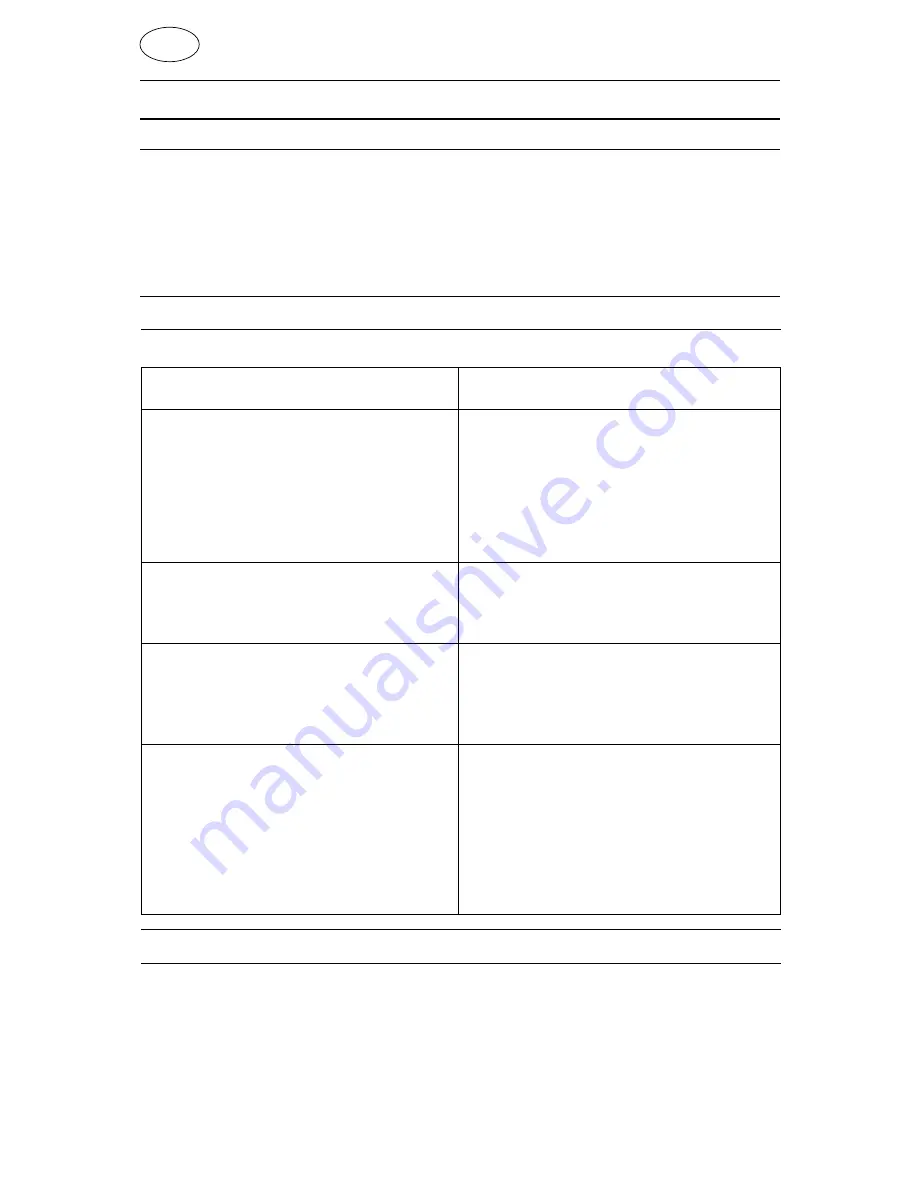

P

Po

os

ss

siib

blle

e

ffa

au

ulltts

s

a

an

nd

d

m

me

ea

as

su

urre

es

s

tto

o

tta

ak

ke

e

When ordering a spare part, please state the type and serial number of the machine as

well as number of the spare part, according to the spare parts list.

This will simplify dispatch and ensure you get the right part.

T

Ty

yp

pe

e

o

off

ffa

au

ulltt

No arc is generated by the welding

power source.

The welding current is interrupted in the

course of welding.

The thermal cut-out trips frequently.

Poor welding result.

M

Me

ea

as

su

urre

e

•

Make sure the mains switch is on.

•

Check that the welding and return

cables are properly connected.

•

Make sure the welding current set is

correct.

•

Verify that the welding process is cor-

rectly selected

•

Check if the thermal cut-out has trip-

ped (the yellow indicating led on the

front panel is on).

•

Check the mains fuse.

•

Check that the filter is not packed with

dust.

•

Check that the ratings of the welding

power source have not been exceeded

(overload of the power source).

•

Check that the welding and return

cables are properly connected.

•

Make sure the welding current set is

correct.

•

Check that there is nothing wrong with

the electrodes.

•

Verify that the welding process is cor-

rectly selected

8

ORDERING OF SPARE PARTS

7

FAULT TRACING

6

6..1

1

C

Clle

ea

an

niin

ng

g

Normally it is sufficient to blow the welding power source clean regularly using dry com-

pressed air (reduced pressure), and to clean the filter in the front regularly.

In dusty and dirty environment the welding power source should be cleaned at shorter

intervals.

GB

51

6

MAINTENANCE