Page 35

Notice G05 - 3 590 503

Issue: 11/2011 - Rev.A

ERVOR (SCA) - 6, Rue Désiré Granet - Z.I. du Val d'Argent - 95100 ARGENTEUIL FRANCE

(33) 01 34 11 50 00

(33) 01 34 11 50 10

Web : www.ervor.com - Email : [email protected]

11 - E - 1 - MOUNTING OF RINGS

It is recommended that piston ring spreaders are used for ease of assembly and to avoid damaging

the piston rings or grooves.

Do not use cutting tools (scriber etc....)

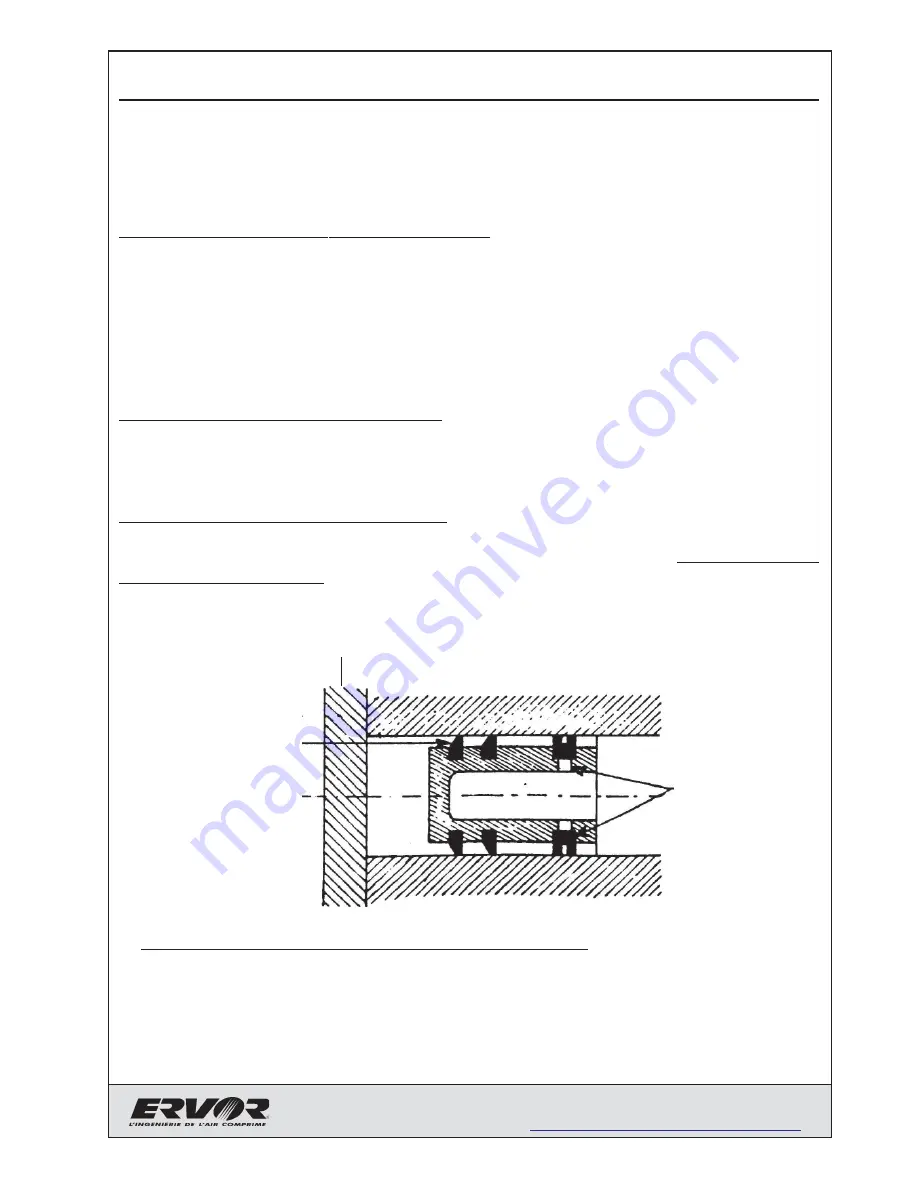

GENERAL ARRANGEMENT OF SEGMENTATION

The segmentation of the piston is arranged as follows :

- anti-leak piston rings at the head of the piston = on the cylinder head side

- scraper piston rings at the back of the piston = on the casing side

(scraper piston rings with holes for the return flow of oil to the casing are fitted in the grooves : see

figure below)

MOUNTING OF SCRAPER PISTON RINGS

There is no special direction for mounting

MOUNTING OF ANTI-LEAK PISTON RINGS

Anti-leak piston rings used in ERVOR compressors are conical. Therefore it is imperative to mount

them in the correct direction.

A mark is etched on one of the faces of the anti-leak piston rings.

The piston ring should be mounted so as to place this mark on the cylinder head side (see below)

CHECKING OF PISTON RING PLAY IN THEIR GROOVES

The piston rings fitted in their respective grooves must slide freely.

Mounting play

= 0,015 to 0,02 mm

After mounting the piston rings, shake the piston to ensure that all piston rings slide

freely in their respective grooves.

RETURN OIL

ANTI LEAK PISTON

RING MARKED FACE

CYLINDER HEAD