Sump Cleaner

23

W

e

e

k

l

y

M

o

n

t

h

l

y

6

M

o

n

t

h

s

12

M

o

n

t

h

s

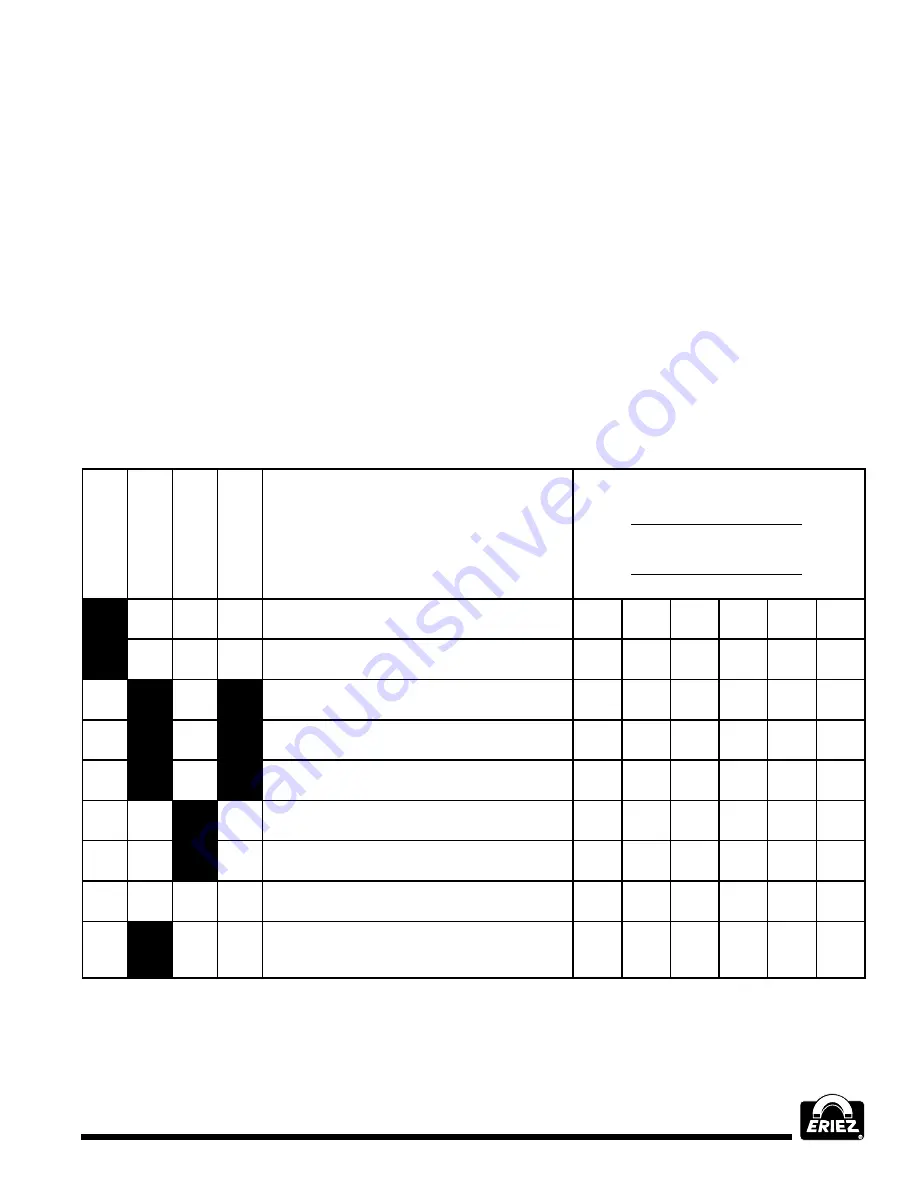

Maintenance

Schedule for Electric Motor

Sump Cleaners

Maintenance Log

Date placed into service:

Record date of service below:

Inspect suction and discharge hoses;

replace as needed

Inspect filter basket sleeve; replace as need-

ed. Inspect basket lifting rings for corrosion

Inspect tank for sludge buildup; clean as

needed

Check blower oil level (add SAE-40

non-detergent oil as needed)

Grease blower; (use No. 2 bearing grease -

500 hours)

Grease motor bearings (use No. 2 bearing

grease)

Grease wheels and casters; (use No. 2

bearing grease)

Change blower oil; (use SAE-40

non-detergent oil - 1500 hours)

Drain blower mufflers if equipped with

optional sound reduction mufflers (drain

plug is on lower end of muffler)

3-phase Maintenance Schedule

9. To discharge clean fluid to refill a machine

sump:

close the suction inlet ball valve V1, attach

the 1-1/2" hose to the discharge port, place the

discharge nozzle in the machine sump, push the

DISCHARGE button, and depress the discharge

hose nozzle valve.

A. Be sure the suction inlet ball valve is fully

closed before operating in the DISCHARGE

mode!

B. IMPORTANT! Be sure the suction inlet ball

valve is fully closed or fully open, depending

on the desired operation (closed-discharge,

open-suction). Failure to do so will allow

particulates to enter the valve seat and

seize the valve.

C. Stop the motor as soon as fluid stops passing

through the hose.

D. The sump cleaner will discharge all but

about an inch of fluid in the bottom of the

compartment. This is unimportant if the

compartment cleaner is used for one type

of coolant only. If different coolants are to

be handled in that compartment, remove

its drain plug to empty it completely.

3-phase Electric Dual Tank

Operation

(contd.)

Summary of Contents for FJ-310A

Page 27: ...Sump Cleaner 27...