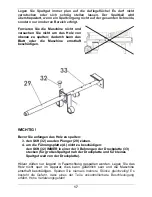

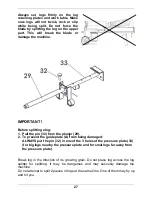

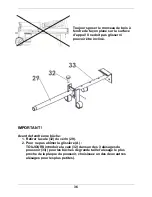

29

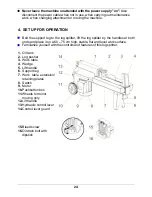

7. MAINTENANCE

To prolong the life of the log splitter, we advise you to consider the following

maintenance prescriptions, so that the machine will carry out heavy jobs for years

to come.

Make sure the log splitter is unplugged, before

carrying out any maintenance jobs.

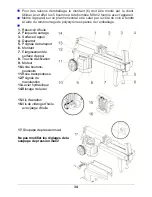

Replacing hydraulic oil

Replace the hydraulic oil in the log splitter after every

150 hours of use or every 2 years. Take following

steps to replace it:

•

Make sure all moving parts stop and the log

splitter is unplugged.

•

Unscrew oil drain bolt with dipstick to remove it.

•

Turn the log splitter on the support leg side over

an 4 liters capacity container to drain the

hydraulic oil off.

•

Turn the log splitter on the motor side and refill

2,4 litres fresh hydraulic oil.

•

Clean the surface of the dipstick on the oil drain

bolt and put it back into the oil tank while

keeping the log splitter vertically.

•

Make sure the level of the refilled oil is just

between 2 grooves around the dipstick.

•

Clean the oil drain bolt before thread them back.

Make sure they are tightened to avoid leakage

before placing the log splitter horizontally.

Recommended hydraulic oil:

Shell Tellus 22

Mobil DTE 11

Aral Vitam GF 22

BP Energol HLP-HM 22

Warning: always respect the regulations in force for disposing of old oil (not

in the sewer!). Use oil of the same kind as that already in the machine; do

not mix different types of oil!

Refilling the hydraulic oil

Periodically check the oil level to ensure it is between 2 grooves around the

dipstick. Upon lower oil level, oil refilling is required.

Sharpening the wedge:

after using the log splitter for some time, sharpen the

wedge of the machine using a fine-toothed file and smooth any burrs or crushed

area along the cutting edge.

Summary of Contents for 77205

Page 45: ...43...

Page 46: ...44 MONTAGE INSTRUCTIES MONTAGE ANWEISUNGEN ASSEMBLY INSTRUCTIONS NOTICES DE MONTAGE...

Page 50: ...48 NOTES...