Introduction

8

❏

If fluid enters your eyes, rinse immediately with water. Failure to observe this

precaution could result in bloodshot eyes or mild inflammation.

❏

If swallowed, induce vomiting and consult a physician immediately.

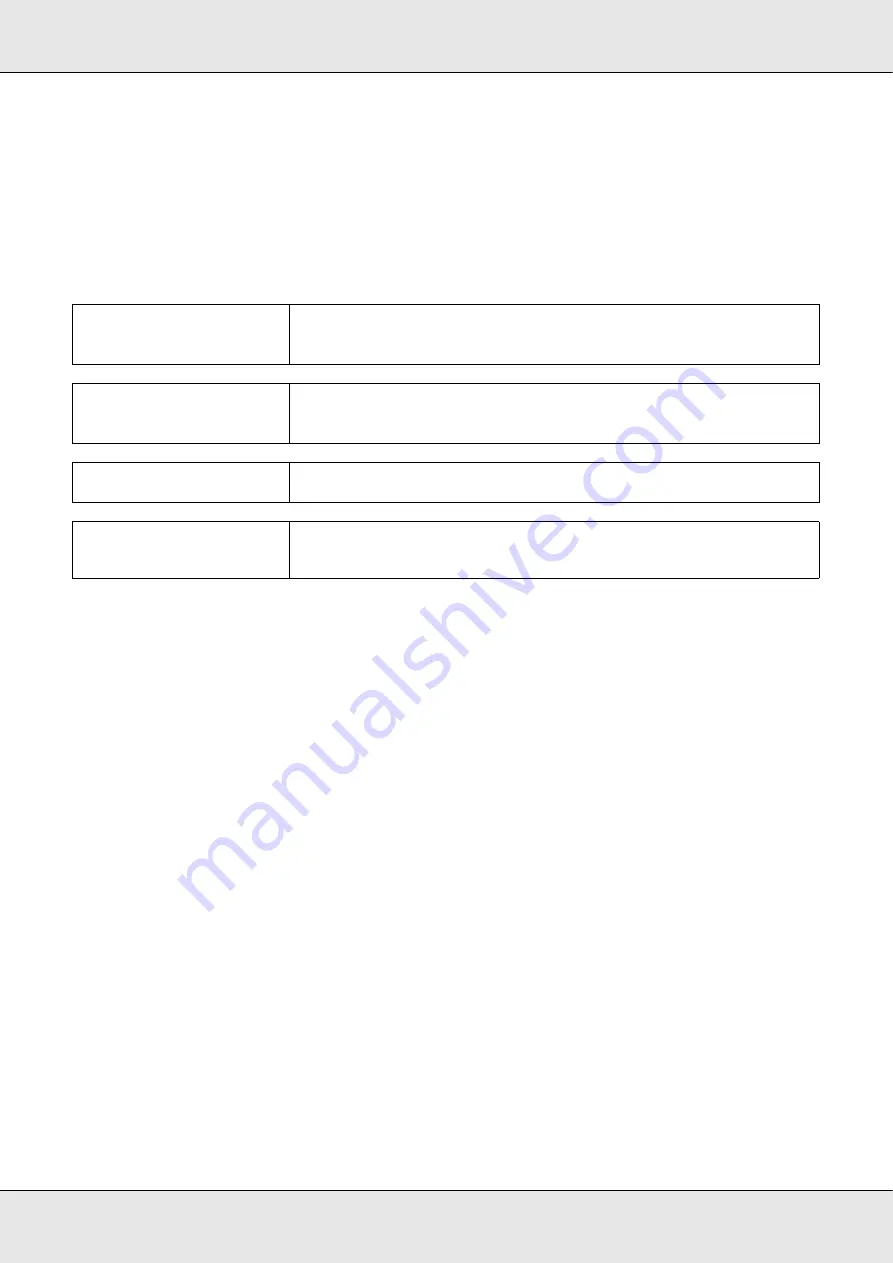

Warnings, Cautions, Important and Notes

w

Warning:

Warnings must be followed to avoid serious bodily injury.

c

Caution:

Cautions must be followed to avoid bodily injury.

Important:

Important must be followed to avoid damage to this product.

Note:

Notes contain useful or additional information on the operation of this

product.