4.1.7 Platen Gap Adjustment

This adjustment is required when the carriage unit is replaced or removed from the printer

mechanism. Adjust the distance between the printhead nose and the paper surface to 1.1 mm.

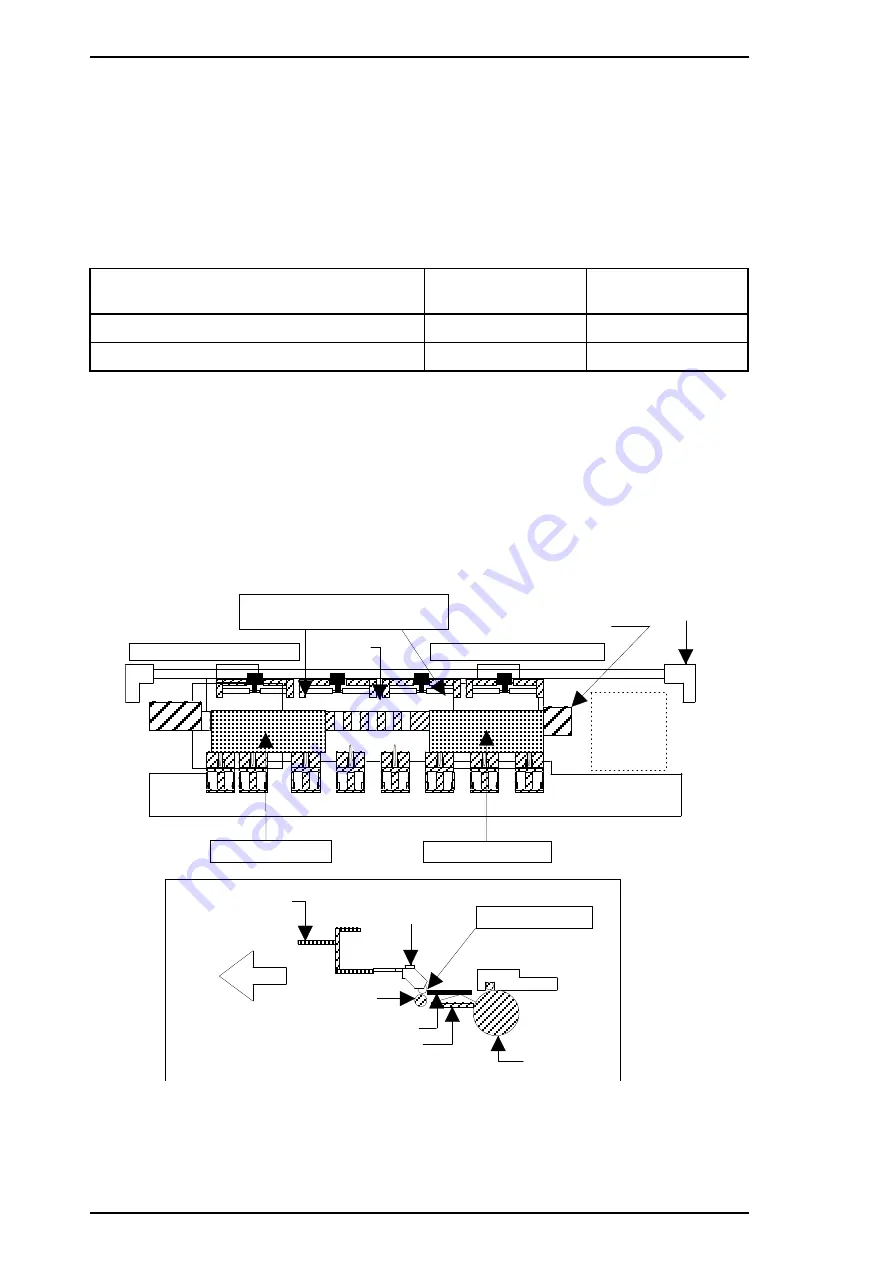

1.

Attach a thickness gauge (commercially available) to the left side adjustment position on the

paper guide plate, as shown in the figure below, so that one side hooks the paper feed pinch

roller unit.

2.

Move the carriage unit manually onto the thickness gauge.

Table 4-2. Gap and Adjustment Direction

Gap between Head Nose and Gauge Surface

Left Bushing

Right Bushing

Narrow

CW

CCW

Spread

CCW

CW

3.

Rotate the parallelism adjustment bushing, attached to the left and right ends of the carriage

guide shaft, when the black and color printheads contact the thickness gauge.

4.

After attaching the printheads to the gauge surface, verify that the gap between the carriage

roller and the front frame is less than 0.04 mm. (See Figure 4-16.)

5.

Attach the 1.1 mm thickness gauge to the right side adjustment position on the paper guide

plate, as shown below, so that one side hooks the paper feed pinch roller unit.

Note:

When checking the gap between the carriage roller and the front frame, use the thickness

gauge or the paper guide plate. If the gap is correct the gauge cannot be installed into the

gap. If the gap is incorrect, the gauge can be inserted in the gap.

Attach the thickness gauge

under the PF pinch roller unit.

Left Adjustment Position

Right Adjustment Position

Paper Gui de Plate

Bus hi ng

Pu mp Un it

Eject Fra me

Thickn ess Gaug e

Thi ckness Gauge

Front

Fron t Frame

PF Pinch Roller

Unit

Attachment Poi nt

Tension Ro ller

Thickn ess Gaug e

Pa pe r Gu id e

Pla te n

Figure 4-18. Adjusting the Platen Gap

Adjustments

Stylus Pro XL

4-16

Rev. A

Summary of Contents for Stylus pro 7700m

Page 1: ...EPSON COLOR INKJET PRINTER Stylus Pro SERVICE MANUAL EPSON 4004825 ...

Page 122: ... 5 IC6 Q2 R135 and CN13 are not mounted on the C164 MAIN Board Stylus Pro ...

Page 123: ...Figure A 3 C164 MAIN Board Circuit Diagram 2 Stylus Pro Service Manual Appendix Rev A A 9 ...

Page 124: ...Figure A 4 C137 PSB Board Circuit Diagram Stylus Pro Service Manual Appendix Rev A A 11 ...

Page 125: ...Figure A 5 C137 PSE Board Circuit Diagram Rev A A 12 A 12 Rev A ...

Page 126: ...Figure A 6 C137 PNL Board Circuit Diagram Stylus Pro Service Manual Appendix Rev A A 13 ...

Page 128: ...Figure A 8 C137 PSB PSE Board Component Layout Stylus Pro Service Manual Appendix Rev A A 15 ...

Page 129: ...Figure A 9 C137 PNL Board Component Layout Rev A A 16 A 16 Rev A ...

Page 131: ...Figure A 11 Stylus Color Pro Exploded Diagram 2 Rev A A 18 A 18 Rev A ...

Page 132: ...Figure A 12 Stylus Color Pro Exploded Diagram 3 Stylus Pro Service Manual Appendix Rev A A 19 ...

Page 139: ...EPSON Printed in Japan 95 05 30 A ...