From the computer

In auto adjustment (Bi-D 2-color), an adjustment

pattern is printed on the loaded paper, read by the

sensors, and the optimum adjustment value is registered

to the printer. It takes about 6 minutes to complete the

adjustments.

In most cases, head alignment can be performed

successfully with just this operation. We normally

recommend this method as this is the simplest method.

U

“From the computer” on page 130

From the printer

You can perform auto or manual adjustments. You can

also select

Uni-D

,

Bi-D 2-color

, and

Bi-D All Color

adjustments from each menu.

❏

Auto adjustment

The sensor reads the adjustment pattern printed on

the paper, and automatically registers the optimum

adjustment value to the printer. It takes about 3 to

10 minutes to complete the adjustments. The time

required varies depending on the menu selected.

❏

Manual adjustment

Visually check the adjustment patterns printed on

the paper, and enter the optimal adjustment values.

Use this if you cannot perform auto adjustment, or

if you are not satisfied with the adjustment results

when using Auto.

The following three menus are available for manual

adjustment.

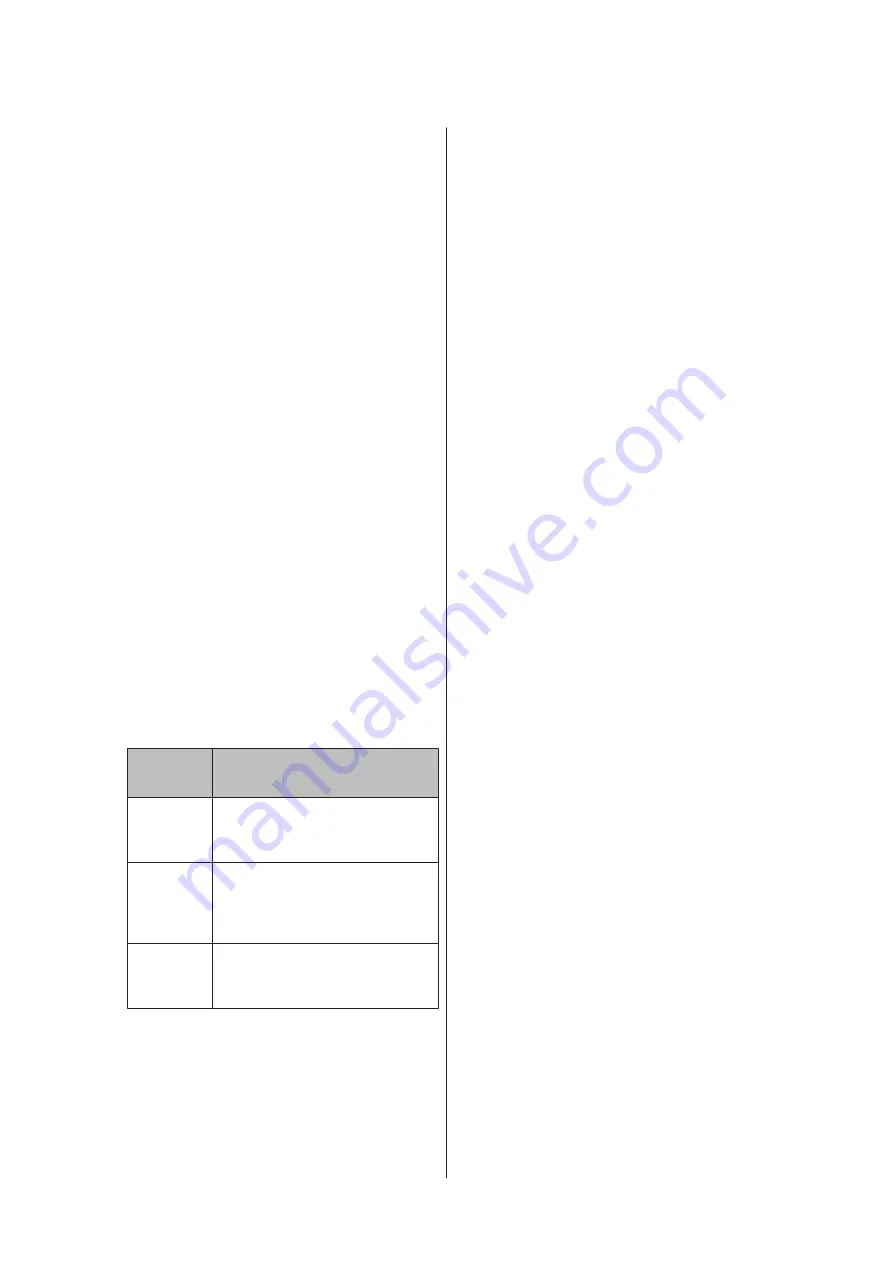

Item

Name

Explanation

Uni-D

Adjusts differences in the print

position for uni-directional printing

for each color based on Light Cyan.

Bi-D

2-color

Adjusts differences in the print

position for bi-directional printing

for two colors, Light Cyan and Vivid

Light Magenta.

Bi-D All

Color

Adjusts differences in the print

position for bi-directional printing

for all colors.

It takes about 17 minutes to print an adjustment

pattern. The time required varies depending on the

menu selected.

U

“From the printer” on page 131

Notes on Head Alignment

Adjustments are made depending on the paper

loaded in the printer.

Make sure that the paper is loaded correctly, and that a

Select Paper Type

is selected.

U

“Loading and Removing the Roll Paper” on

U

“Loading and Removing Cut Sheets” on page 34

When adjusting using commercially available paper,

make sure you register the custom paper in advance.

U

“Before Printing on Commercially Available

Make sure that nozzles are not clogged.

If nozzles are clogged, adjustment may not be

performed correctly. Print the check pattern, perform a

visual inspection, and perform head cleaning if

necessary.

U

“Checking for clogged nozzles” on page 126

Auto adjustment cannot be performed when using

the following paper.

❏

Plain Paper

❏

Enhanced Matte Poster Board

❏

Transparent or colored paper

Perform manual adjustment when using these types of

paper.

U

“From the printer” on page 131

When performing auto adjustment, make sure that

no external light (direct sunlight) enters the printer.

Otherwise, the printer's sensors may not read the

adjustment pattern correctly. If auto adjustment cannot

be performed even after making sure no external light is

entering the printer, perform manual adjustment.

U

“From the printer” on page 131

From the computer

Before starting this procedure, be sure to read the

following:

U

“Notes on Head Alignment” on page 130

SC-P9000 Series/SC-P7000 Series/SC-P8000 Series/SC-P6000 Series User's Guide

Maintenance

130