4-51

CONFIDENTIAL

EMP-1825/EMP-1815/EMP-1810

SEIKO EPSON

Revision:C

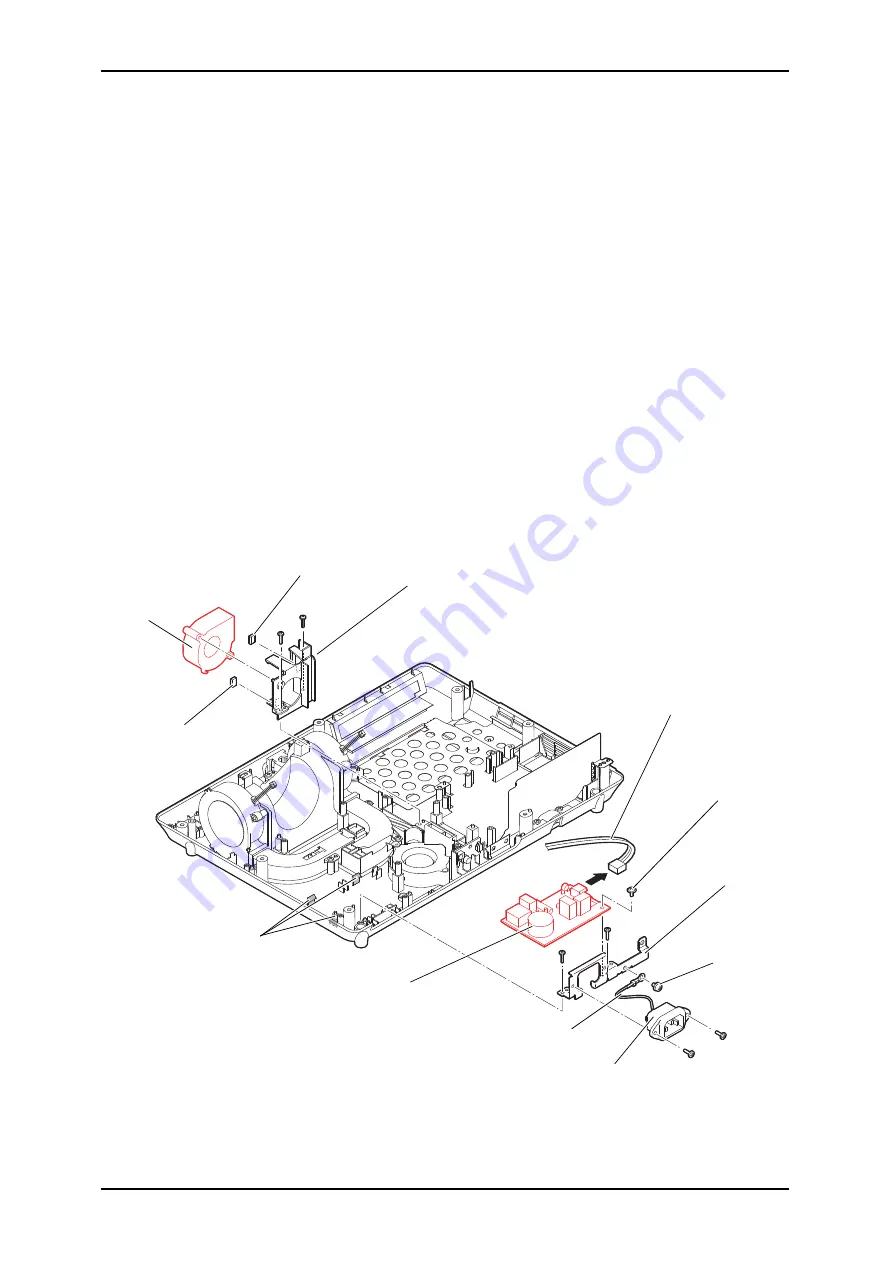

4.5.3 Removing the PS Ballast Assy.(2) (Filter Board Unit)/Lamp Fan

Removing the Filter Board Unit

1). Remove the two screws (C.B.P-TITE SCREW,2.5X10,F/ZN-3C) that secure the AC

Inlet Fastening Plate.

2). Disconnect the AC Cable from the connector on the Filter Board Unit, and unlock the

three hooks and remove the Filter Board Unit together with the AC Inlet Fastening Plate.

3). Remove the screw (C.P.(S-P1)SCREW,4X6,F/ZN-3C) that secures the AC Inlet’s GND

cable.

4). Remove the two screws (C.B.SCREW,3X8,F/ZB-3C) that secure the AC Inlet, and

remove the AC Inlet Fastening Plate.

5). Remove the screw that secures the Filter Board Unit’s GND, and remove the Filter Board

Unit.

Removing the Lamp Fan

6). Remove the two screws (C.B.P-TITE SCREW,2.5X10,F/ZN-3C) that secure the Lamp

Duct, and remove the Lamp Duct together with the Lamp Fan from the Lower Case.

7). Remove the Lamp Fan from the Lamp Duct.

8). Remove the two BS Sheet FIF from the Lamp Duct.

Figure 4-61.

Lamp Fan

Lamp Duct

BS Sheet FIF

BS Sheet FIF

Filter Board Unit

AC Inlet

Fastening

Plate

AC Inlet

AC Inlet’s

GND cable

C.P.(S-P1)

SCREW,4X6,

F/ZN-3C

C.C.SCREW,

3X6,F/ZN-3C

AC Cable

hooks

Summary of Contents for EMP-1815

Page 1: ...Service Manual Data Projector EMP 1825 EMP 1815 EMP 1810 ...

Page 9: ...Chapter 1 Product Specifications ...

Page 16: ...Chapter 2 Theory of Operation ...

Page 23: ...Chapter 3 Troubleshooting ...

Page 44: ...Chapter 4 Disassembly Assembly ...

Page 105: ...Chapter 5 Adjustment ...

Page 113: ...Chapter 6 Appendix ...