Section 3: Getting Started

23

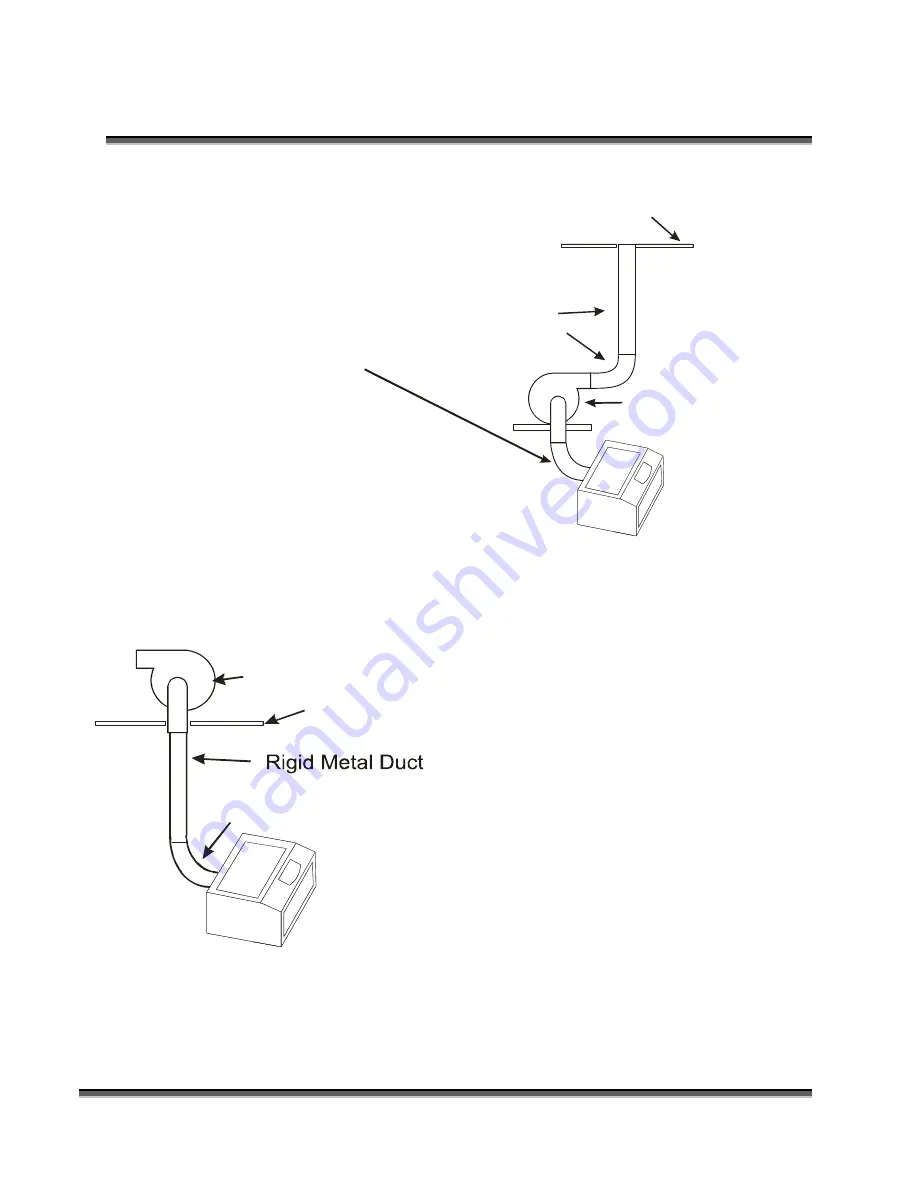

4” (100 mm) flexible aluminum duct

or rigid galvanized sheet

metal (Do not use vinyl,

plastic or “soft” flexible duct).

Exhaust Blower

Roof or exterior wall

Exhaust Blower

Roof or exterior wall

4” (100 mm) flexible aluminum duct

or rigid galvanized sheet

metal (Do not use vinyl,

plastic or “soft” flexible duct).

Summary of Contents for FiberMark Fusion 13000

Page 2: ...ii THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 4: ...Contents at a Glance iv THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 8: ...Table of Contents viii THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 10: ...Fire Warning x THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 14: ...Introduction xiv THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 15: ...Epi ilog 1 M g La 1 anual ase er S Setu up ...

Page 16: ...2 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 26: ...S Section 1 n 1 S 12 afety ...

Page 40: ...Section 3 Getting Started 26 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 78: ...Sectio 300 D 600 D on 6 U DPI DPI Using t 6 the Ep 64 pilog D Dashbo oard ...

Page 106: ...Section 6 Using the Epilog Dashboard 92 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 107: ...Ba asic 9 M c O 93 anual per rati ions ...

Page 108: ...94 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 164: ...150 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 166: ...Section 13 In Case of Difficulty 152 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 172: ...Section 14 Specifications 158 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...

Page 180: ...APPENDIX A 166 THIS PAGE WAS INTENTIONALLY LEFT BLANK ...