A.

Set the Time of Day Setting.

1. Locate the up and down buttons on the face of the control valve.

2. Simply push the up button to set the time forward, or the down button to set the time

backward. On the right of the display there is a P.M. indicator dot. Holding the button in

will advance the time more quickly. It will start slow at first, and then increase in speed

the longer you continue to hold the button in.

3. Release the buttons when you have set the control to the current time of day.

B.

Program the feed water hardness.

1. Enter the programming mode by pressing both the up and down buttons for (5) seconds.

2. The first setting displayed is the feed water hardness listed in grains per gallon. The

factory default value is 18 grains.

3. Change the setting to the feed water hardness in your area by pushing the up or down

button. We recommend setting the value about 3 grains higher than what the actual level

is to compensate for seasonal changes in the feed water hardness. You can find out what

your feed water hardness is by contacting the municipality or company providing the

water service to your home.

4. Press the

Extra Cycle

button to advance to the regeneration time setting.

C.

Program the regeneration time.

1. The factory default regeneration time setting is 2:00 A.M.

2. To change the time of day the system will regenerate,

simply push the up button to

set the time forward, or the down button to set the time backward. On the right of the

display there is a P.M. indicator dot. Holding the button in will advance the time more

quickly. It will start slow at first, and then increase in speed the longer you continue to

hold the button in.

3. To accept the setting and advance forward to the

In Service

position, press the

Extra

Cycle

button.

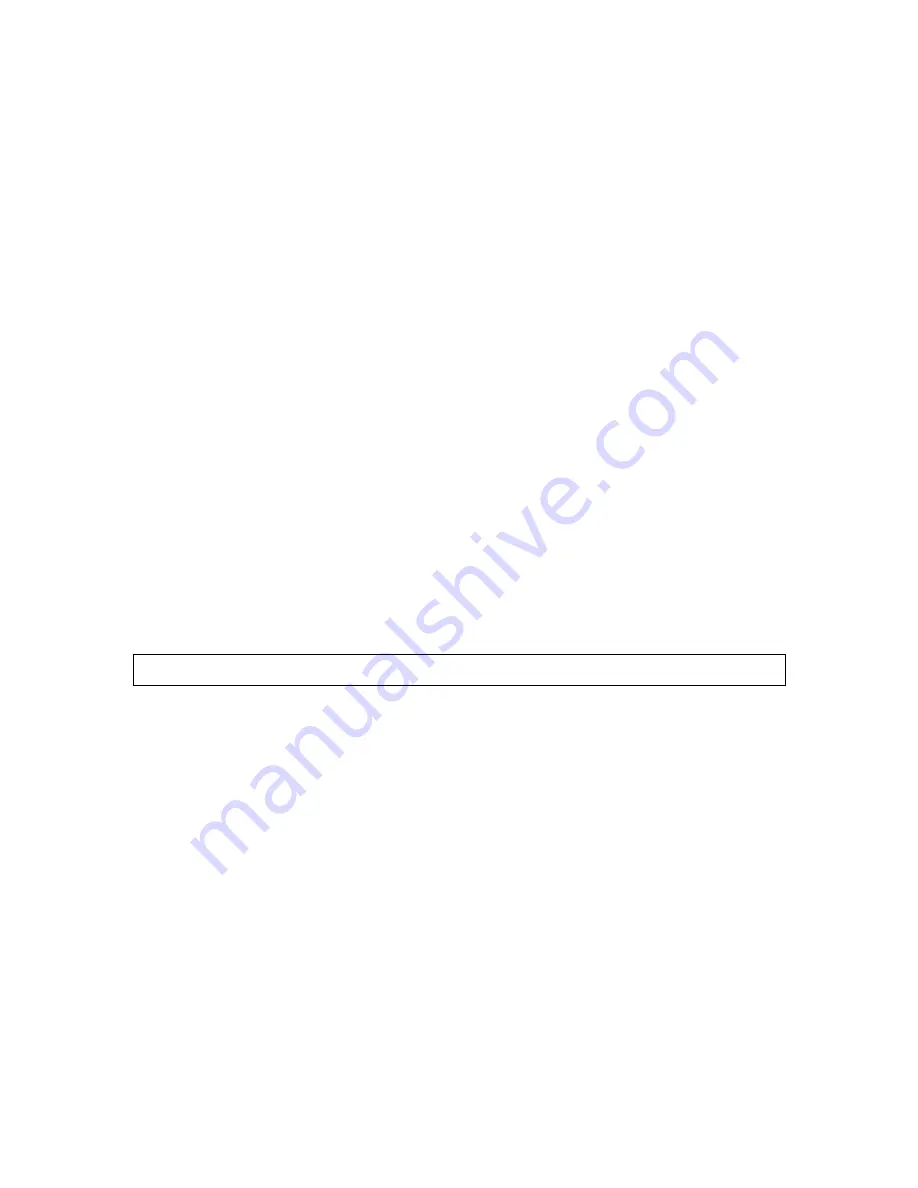

FACTORY DEFAULT SETTINGS

Model

Hardness

Capacity

Salt

Calendar Override

(Grains/gallon) (Kilo grains)

(Pounds)

(Days)

2-F70MDV-342 / ET42H

18

20

6

15

2-F70MDV-350 / ET50H

18

24

7

15

2-F70MDV-364 / ET64H

18

31

9

15

USE AND CARE

A.

Type of System

Your water softener is a fully automatic

Demand Initiated

, metered

system. This means the

softener meters, or keeps track of, the water used in the home. It uses this information to

determine when to perform the regeneration, or cleaning cycle. The control of the softening

process automatically adjusts to your water use. For example, if you have company and your

water use increases substantially, the softener will adjust to insure you don’t run out of soft water.

If you go away for a time and are not using any water in the home, the softener will adjust again

and not perform a regeneration cycle thereby saving salt and water.

B.

Type of Salt

Basically, salt is salt. However, some makes of salt contain more dirt in the bag than others. We

recommend Morton™ or Diamond Crystal™ salt pellets, but any type will work. Salt is readily

available at most grocery stores and home improvement centers.

C.

Type of Potassium

Potassium can also be used in the water softener. When Potassium is used however, the softener

control valve will need to be adjusted. Add 3 grains to the feed water hardness setting i.e. feed

water = 18 3 for potassium = 21 grains entered for the feed water setting. Also keep the

level of potassium in the brine tank low.

D.

Amount of Salt or Potassium

We recommend keeping the level of salt in the brine tank about half full for most households.

Larger households can start out with more. Let the salt level drop down to the water level before

adding more salt. Potassium should be kept as close to the water level as is practical to help

prevent a “salt bridge”. Periodically you may experience a salt bridge. A salt bridge occurs when

Form ETWS 2/07

Page 9 of 20

Summary of Contents for ET42H

Page 13: ...Form ETWS 2 07 Page 13 of 20...

Page 14: ...Form ETWS 2 07 Page 14 of 20...

Page 15: ...Form ETWS 2 07 Page 15 of 20...