-

6

-

Thi s

appliance

is

designed

for

appl yi ng

preformed

thermopl asti c r oad mar kings.

Users of the 3000 EX torch must r ead thi s user's gui de

completel y and must be trained for the applications that require

the use of this appliance.

Thi s user's guide must be kept for futur e reference.

Close the val ve of the gas bottle w hen not in use.

Pr ess the trigger to empty the gas hose and release the

pressure.

M aintain oversi ght of the treated ar ea for a ti me determi ned b y

the user depending on use condi ti ons.

Thi s appliance, like all other gas appliances, consumes air and

produces combusti on fumes that contai n CO2 and CO. Exposure

to hi gh concentr ati ons of the latter gas is lethal.

Never work in a basement.

Before using the appliance, make sure that you are conforming to the

guidelines for using liquid gas.

In operation, this appliance produces a flame. Do not point the flame towards

yourself, other persons or animals, towards the gas bottle or the hose,

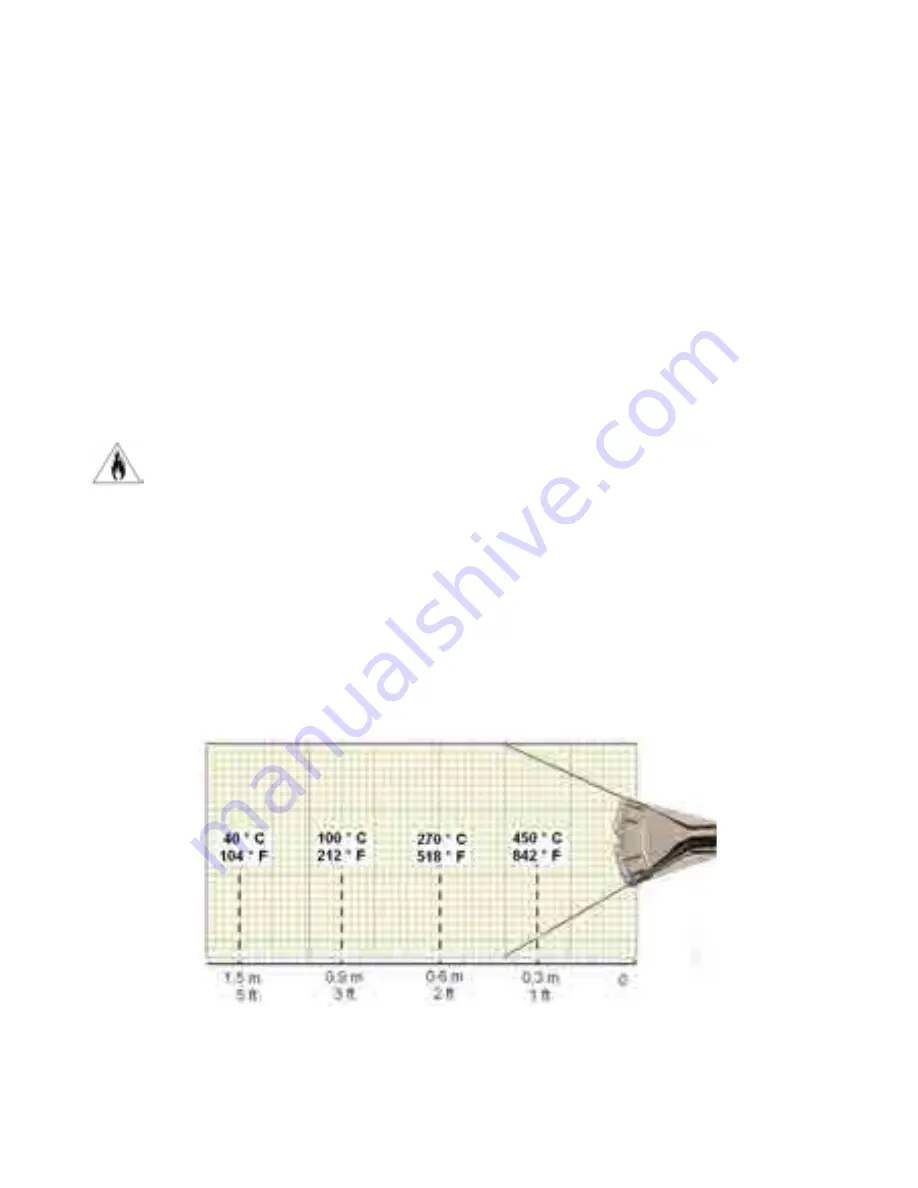

In operation, the appliance creates a

danger zone up to 1.5 metres (5 feet)

in front

of the fire nozzle.

We draw the attention of operators to the fact that within the danger zone, there is a

possible risk of burning for persons and animals, and goods can be damaged or

catch fire.

Always contact your FLINT distributor for all maintenance work and spare parts.