16

010.1220.0719 01.21

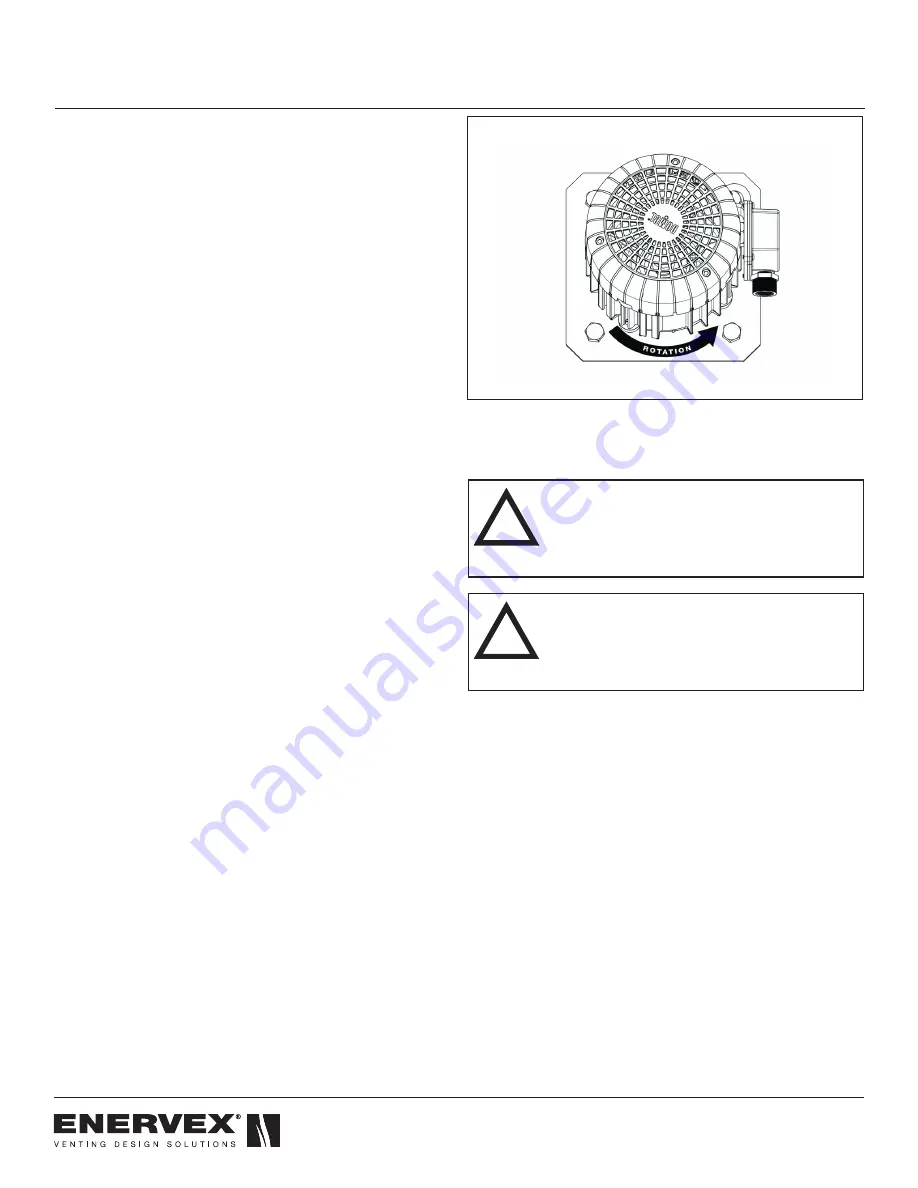

by an arrow on the motor end cover. There are holes in the

end cover that allow you to see the cooling vanes, but it is

hard to see the rotation unless the fan is running very slowly.

For a more precise determination, you can also look inside

the fan housing as shown in Fig. 15. The arrow shown (not

actually inside fan housing) shows the proper rotation. It

is possible for the fan to operate with improper rotation.

However, the fan will only provide 25–30% of full capacity, will

cause damage to components and should be avoided.

Fan rotation can be changed on the EDrive by switching the

attachment position of any two power leads.

4.11 INSTALLING A PROVEN FLOW SYSTEM

If required by local codes, a safety system can be interlocked

with the appliance(s) to prove fan operation. The safety

system could utilize a Proven Draft Switch (PDS), a thermal

switch, a flow switch or a sail switch. The device must be

interlocked with the appliance(s) so it shuts down in case of

fan failure or power failure.

Please refer to the PDS Installation Manual for wiring

instructions.

If the installation includes a MEC24 Exhaust Control or

EBC 30/31 Modulating Pressure Fan Control, a PDS is not

required as the function is integrated into the control.

For more information about alternative safety system, please

consult ENERVEX.

Fig 15

AVERTISSEMENT

La turbine doit impérativement tourner dans le bon

sens. Une rotation en sens inverse entraînerait de

mauvaises performances de soufflage, une surcharge

du moteur voire un grillage du moteur.

!

WARNING

Correct direction of wheel rotation is critical.

Reversed rotation will result in poor air performance,

motor overloading and possible burnout.

!

Summary of Contents for BEF 225x

Page 23: ...23 010 1220 0719 01 21...