14

010.1220.0719 01.21

voltage transients, typically originating from lightning strikes

or switching of high power equipment on the same supply.

When carrying out a HiPot (Flash) test on an installation

in which the drive is built, the voltage surge suppression

components may cause the test to fail. To accommodate

this type of system HiPot test, the voltage surge suppression

components can be disconnected by removing the VAR

screw After completing the HiPot test, the screw should

be replaced and the HiPot test repeated. The test should

then fail, indicating that the voltage surge suppression

components are once again in circuit.

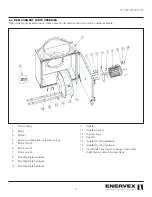

4.6 Electrical Connection of the Motor and EDrive

The motor should be connected to the EDrive E3 U, V, and

W terminals using a suitable 3 or 4 core cable. Where a 3

core cable is utilised, with the shield operating as an earth

conductor, the shield must have a cross sectional area at

least equal to the phase conductors when they are made

from the same material. Where a 4 core cable is utilised, the

earth conductor must be of at least equal cross sectional

area and manufactured from the same material as the phase

conductors.

The motor earth must be connected to one of the EDrive E3

earth terminals.

Maximum permitted motor cable length for all models: 100

meters shielded, 150 meters unshielded.

Where multiple motors are connected to a single drive using

parallel cables, an output choke must be installed..

The BEFx Fan sizes 225-355 require four (4) 14AWG

conductors between the EDrive and the Fan motor. (Three

(3) Power lines, and one (1) dedicated Ground wire.)

The BEFx Fan Sizes 225-800 require four (4) 12AWG

conductors between the EDrive and the Fan motor. (Three

(3) Power lines, and one (1) dedicated Ground wire.)

Make all necessary connections to the power and low-

voltage terminals (see wiring diagram).

4.7 Motor Terminal Box Connections

Do not install any mechanical or electro-mechanical switching

devices between the drive and motor. Where a local isolator

is installed close to the motor, this should be interlocked with

the drive control circuit to ensure the drive is disabled when

the motor is isolated.

Most general purpose motors are wound for operation on

dual voltage supplies. This is indicated on the nameplate

of the motor. This correct voltage setting must be selected

when installing the motor by selecting either STAR or DELTA

connection. STAR always gives the higher of the two voltage

ratings.

4.8 Wiring Diagram - BEF 225-355x / 1X120V

NOTE: All published voltages relate to power supplied to the

EDrive and NOT the motor.

BEF 225-355x fans operate at 1x120 VAC.

The wiring diagram in Fig. 14 is a typical wiring diagram for a

BEF 225-355x with 120V supply voltage to the motor drive.

The BEFx is listed with an EDrive motor controller which is

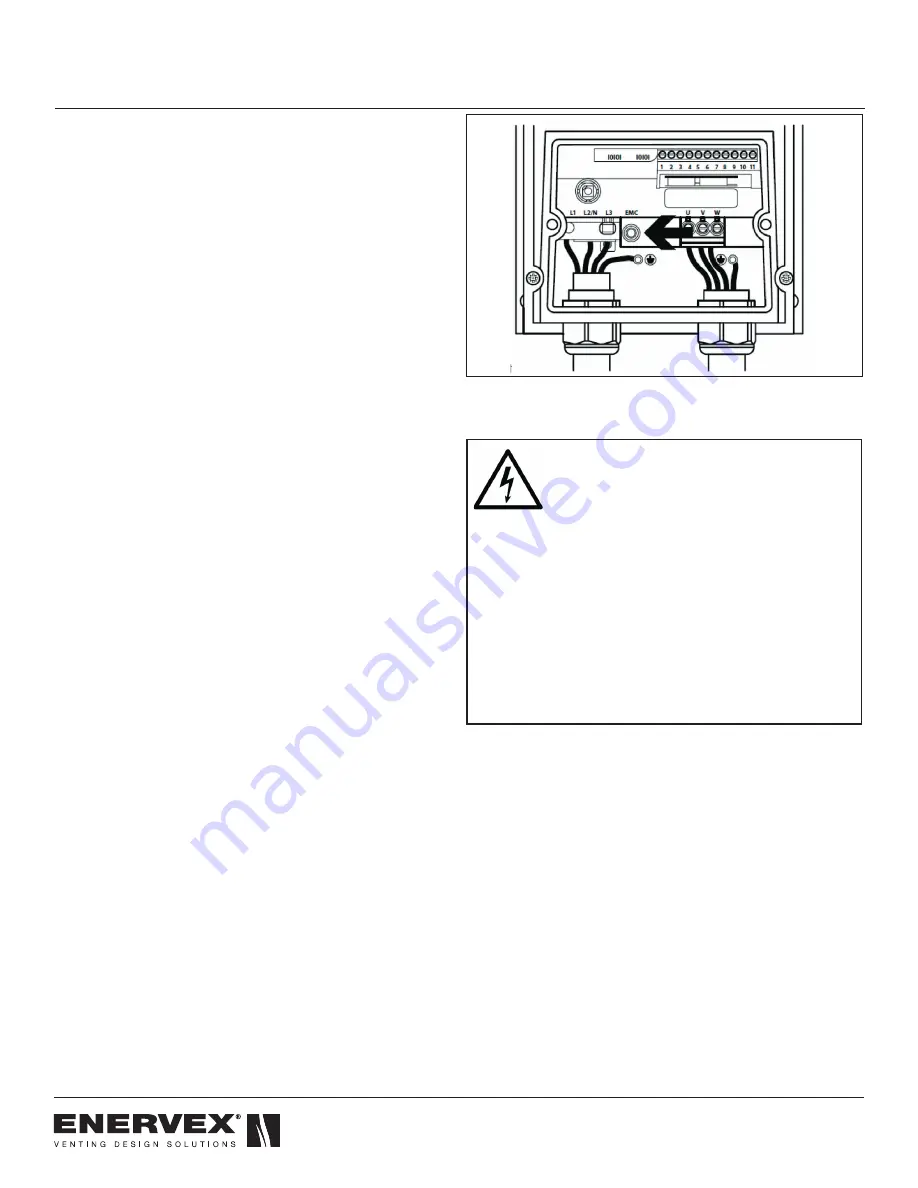

DANGER

This EDrive contains high voltage capacitors

that take time to discharge after removal of

the main supply. Before working on the drive,

ensure isolation of the main supply from line

inputs. Wait ten (10) minutes for the capacitors to discharge

to safe voltage levels. Failure to observe this precaution

could result in severe bodily injury or loss of life.

Cette EDrive contient des condensateurs à haute tension

qui mettent du temps à se décharger après le retrait de

l’alimentation principale. Avant de travailler sur le variateur,

veillez à isoler l’alimentation principale des entrées de

ligne. Attendez dix (10) minutes que les condensateurs se

déchargent à des niveaux de tension sûrs. Le non-respect

de cette précaution peut entraîner des blessures graves ou

la mort.

Fig 13

Summary of Contents for BEF 225x

Page 23: ...23 010 1220 0719 01 21...