13

Oil temperature:

-10 to+70°C

4. Cartridge i lter

Changing cartridge fi lter

Unscrew the i lter screw from the cover using a 4 mm Allen key and pull

out the i lter cartridge. Insert a screwdriver between the i lter and screw,

if necessary, to carefully ease out the i lter. Replace the old i lter by a new

one, pushing it on the i lter screw. Reassemble the cartridge and tighten

171 805 04 03-01

06. INSTRUCTIONS PUMP TYPE BFP 41L3

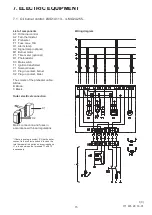

BFP 41L3 operating principle

When the pump is started, oil is drawn from the suction port (S) th-

rough the i lter (H) to the suction port (C) of the gear-set.

The oil then moves to the pressure side of the gearwheel and is thus

pressurised. The pressure is controlled and maintained at a constant

pre-set level by diaphragm (D) of the control valve (P

1

)

The control valve (P

1

) distributes the oil supplied by gear-set (C) bet-

ween the nozzle connection (E) and the return port of the pump (R).

The amount of oil consumed is determined by the pressure set on the

control valve (P

1

) and by the size of the oil nozzle in the nozzle line.

The control valve (P

1

) operates as follows:

- When the oil attains opening pressure, the port to the return side opens.

- The diaphragm and the spring keep a constant pump pressure at the

set value.

- If the pump becomes overloaded, i.e. if an attempt is made to take out

more oil than the gear-set can deliver in the prevailing circumstances,

the oil pressure will fall below the set value causing the valve to close,

by diaphragm (D), to the return port (R) and return to the starting posi-

tion.

This can be remedied by:

- Lowering the pump pressure.

- Reducing the amount of oil delivered, i.e. changing to a smaller nozzle.

- Changing to a pump with higher capacity.

2(3)

H

A

G

R

S

P

V

C

NC

P

1

E

D

6.4 BFP 41L3 operation principle

Summary of Contents for Bentone B1FUV Classic

Page 19: ...19 9 DECLARATION OF CONFORMITY...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...