14

L4442

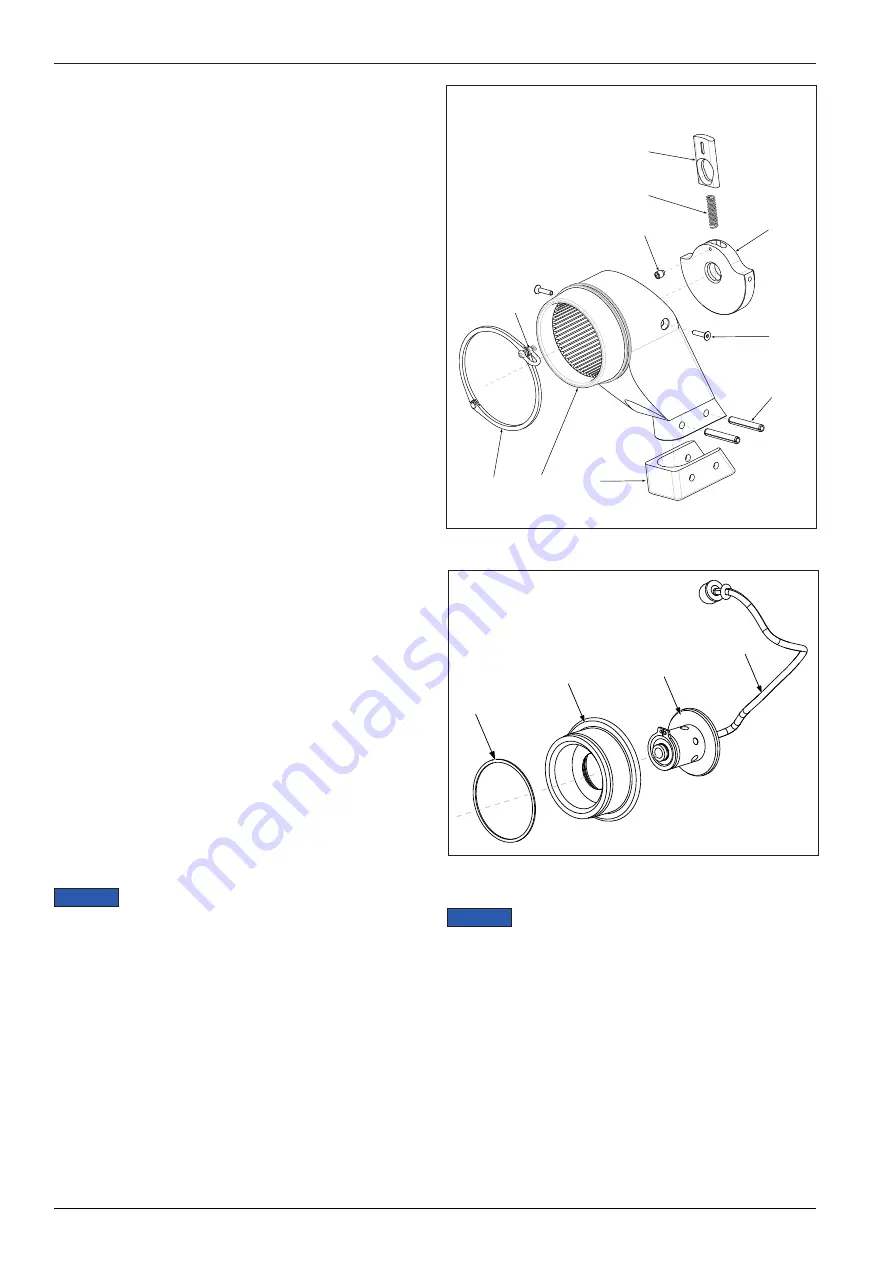

7.2.4 Reaction Arm - Disassembly and Reassembly

(Fig. 16)

•

Disassembly

1.

To remove the wire assembly (36) that is securing

the reaction arm to the wrench body, first unscrew

the wire assembly nut followed by the rest of the

assembly (36).

2.

Remove the reaction arm assembly, including the

retaining plate (4), and shackle ring (38).

3.

Unscrew the two plate screws (35) and remove

retainer (24).

4.

Remove the grub screw (10), followed by the

retainer tab (15) and spring (16).

5.

If required, the shackle ring can be removed from

the reaction arm body by removing the eyebolt

assembly and separating the shackle ring arms.

6.

Clean all exposed components with a mild solvent.

7.

Inspect all parts for damage.

Replace any worn or

damaged parts.

•

Reassembly and Installation

1.

Apply silicon lubricate to all components, except

the two plate screws (35).

2.

Re-assemble the spring (16), retainer tab (15), and

grub screw (10), applying a small amount of Loctite

222 thread sealant on to the grub screw before

installing the assembly into the retainer plate (24).

3.

Fit the retainer plate (24) into the reaction arm body

(2), apply a small amount of Loctite 243 thread

sealant to the threaded mounting holes before

inserting plate screws (35).

4.

If removed, reattach the shackle ring (38), secured

into place with the eyebolt. Loctite 222 should be

applied to the thread of the eyebolt during assembly.

5.

Install the wire assembly (36) into the rear of the

piston sleeve. Slide the reaction arm (2) onto the

wrench body (1), threading the end of the wire

assembly (36) through the retainer plate (24) and

secure by screwing the hex nut onto the end of the

wire assembly (36).

7.2.5 Square drive Release Button Disassembly

and Reassembly (Fig. 17)

Disassemble the square drive release button

only if it is not operating properly or if it is worn or

damaged.

1.

Remove circlip (13).

2.

Separate the button mechanism (12) from the

retaining block (14).

3.

Clean all parts with a mild solvent. Dry all parts

after cleaning.

4.

Inspect all parts for damage.

5.

Reassemble retaining button assembly (12) and

bushing (14) and secure with circlip (13).

6.

Apply a thin coat of molybdenum disulphide grease

in the areas shown in Figure 10.

NOTICE

13

14

12

37

Figure 17: Exploded Square drive

38

✽

35

33

25

24

16

15

10

❇

2

❇

(eyebolt thread

only)

Figure 16: Exploded Reaction Arm

❇

Apply Loctite 222 Thread Sealant

✽

Apply Loctite 243 Thread Sealant

If a fault develops with the retaining button

assembly (12), the whole assembly will need to be

replaced. It is not recommended that this item be

disassembled.

NOTICE