2

WARNING:

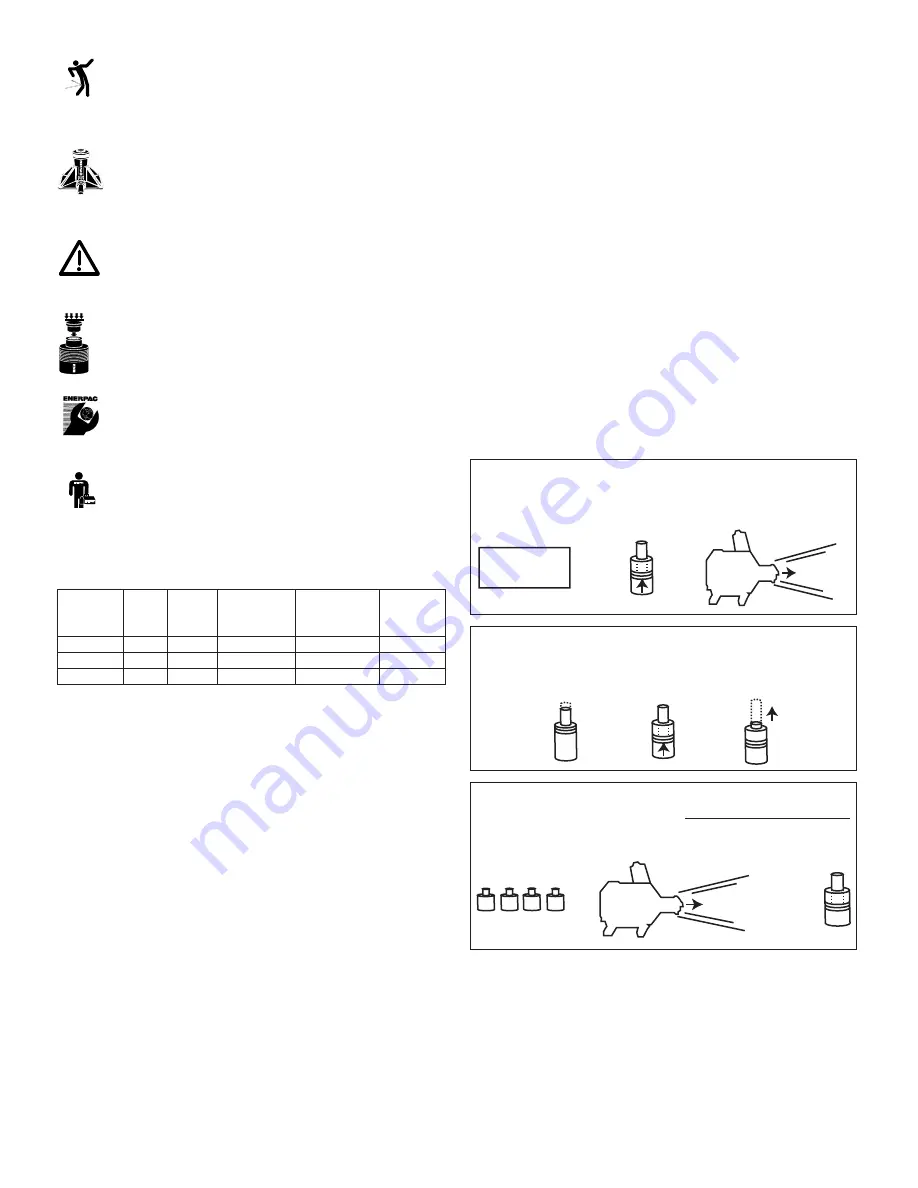

Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers.

If the cylinder becomes extremely overloaded,

components can fail catastrophically causing severe personal

injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD.

Cylinders should be placed on a flat

surface that can support the load. Where applicable, use a

cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid

situations where loads are not directly centered on

the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In addition,

the load may slip or fall, causing potentially dangerous results.

Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

IMPORTANT:

Hydraulic equipment must only be serviced

by a qualified hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING:

Immediately replace worn or damaged parts

by genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fit properly and withstand high

loads.

3.0 SPECIFICATIONS

Note:

Shipping box contains fittings for NPT hook-up. The fitting

with the tapered male threads goes into the 3/8 BSPT air inlet.

Ambient Temperature Range..............-4˚F (-20˚C) to +176˚F (80˚C)

Recommended Oil Temperature ......+59˚F (15˚C) to +131˚F (55˚C)

Minimum Operating Air Pressure ................................40 psi (3 bar)

Maximum Operating Air Pressure ..............................125 psi (9 bar)

Air Consumption ..............................................0.95 cu. ft. per stroke

Reservoir Capacity ..............................................................50 cu. in.

Usable Oil Capacity ..........................................................13.4 cu. in.

Maximum Cycle rate ........................................10 cycles per minute

Air Piston Retract Speed (from full extend)

@ 86 psi (6 bar)............................................................Max. 3.2 sec.

Return Spring Force @ Initial Position....................................57 lbs.

Return Spring Force @ Maximum Compression ..............1041 lbs.

Stroke Sensing Position Before Full Stroke ..........................1.04 in.

Sensing Contact Capacity ......................................30 VDC, 3 amps

4.0 INSTRUCTIONS

4.1 General Description

Air operated hydraulic boosters convert low pressure air to high

pressure hydraulic oil for operating hydraulic cylinders, clamps or

similar devices. Primary booster components are, the air piston and

the hydraulic cylinder plunger. Air pressure, into the booster, exerts

a force against the air piston causing it to move forward. The forward

motion compresses the piston return spring and moves the hydraulic

plunger in the oil cylinder. The plunger compresses the oil in the

cylinder developing high pressure at the outlet port.

Pressure intensification is determined by the air piston to hydraulic

plunger ratio. If the booster ration is 20:1 100 psi air pressure will

produce 2000 psi hydraulic pressure. Air pressure of 80 psi will

produce 1,600 psi hydraulic pressure. To determine actual holding

forces, multiply the effective area of a working cylinder by the

hydraulic pressure being produced.

The result is holding force

in pounds.

4.2 Selecting Cylinders and Boosters

1.

Determine the holding force required for the application.

2.

Determine input air pressure available.

3.

Determine volume of oil required in the hose or pipe from the

booster to the working hydraulic cylinder or clamping devices.

Note:

Any cylinder can be matched with any pump or booster as

long as the pump or booster has enough useable oil capacity (cubic

inches) to transmit and fully extend the cylinder or cylinders.

Your only other consideration is knowing the maximum Hydraulic

Pressure Range (psi) of the selected pump or booster for

determining the "Cylinder Holding Force" of the cylinder or

cylinders.

=

÷

OIL

Useable Oil

Capacity

Pump or

Booster

TO FIND:

Total number of Cylinders

Useable Oil Capacity of Pump

that can be used with = (or) Booster oil Output (cu. in.)

Booster or Pump

Oil Capacity of Cylinder (cu. in.)

OIL

=

x

TO FIND:

Cylinder Oil Capacity

=

Cylinder Effective

x

Cylinder Stroke

(cu. in.)

Area (sq. in.)

(inches)

=

x

Force

(lbs)

Pump or

Booster

Working

Pressure

TO FIND:

Cylinder Holding

=

Cylinder Effective

x

Hydraulic Working

Force (lbs)

Area (sq. in.)

Pressure (psi)

Model No.

Ratio

Oil

Per

Oil Pressure

Max

Piston

Stroke Oil

at 100PSI

Oil

Stroke

Output

Air Pressure

Pressure

B-2009

20:1

5.20 in.

9.30 cu. in.

2000 psi

2500 psi

B-3006

30:1

5.20 in.

6.20 cu. in.

3000 psi

3750 psi

B-5003

50:1

5.20 in.

3.70 cu. in.

5000 psi

6250 psi

®