Oxymax W COS61

Wiring

Hauser

15

4.2

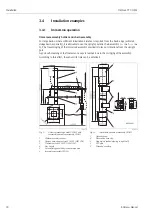

Connection via junction box

To extend the sensor connection beyond the length of the fixed cable, the connection has to take

place using a junction box VS (

15,

Always connect the sensor cable to the junction box with the SXP connector.

The extension to the transmitter depends on the transmitter version, i.e. field device or

panel-mounted instrument.

4.3

Post-connection check

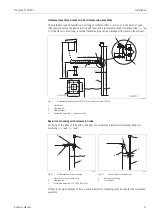

a0004129-en

Fig. 15:

Junction box VS to the field device

1

SXP connector to the field device

2

SXP connector from the sensor

a0004130

Fig. 16:

Junction box VS to the panel-mounted

instrument

2

SXP connector from the sensor

3

Special measuring cable to the transmitter (OMK)

4

Transmitter connection compartment

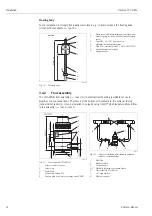

Instrument status and specifications

Remarks

Are the sensor, assembly, junction box or cable damaged?

Visual inspection

Electrical connection

Remarks

Does the supply voltage of the transmitter match the specifications on the

nameplate?

110/230 V AC

24 V AC/DC

Are the installed cables strain-relieved and not twisted ?

Is the cable type route completely isolated?

Power cable/weak current cable

Are the power supply and signal cable correctly connected to the

transmitter?

Use the connection diagram of COM 2x3.

Are all the screws terminals properly tightened?

Are all the cable entries installed, tightened and sealed?

For cable entries lateral: cable loops

downwards for water to be able to drip off.

Are all the cable entries installed downwards or lateral?

1

2

82 / 3.23

80

/

3.15

mm / inch

3

2

YE

GY

PK

BU

BN

GN

WH

87

0

96

97

88

19

18

4