Micropilot FMR56, FMR57 FOUNDATION Fieldbus

Mounting

Hauser

21

5.9

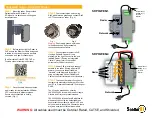

Turning the display

5.9.1

Opening the cover

2.

1.

3 mm

A0021430

1. Loosen the screw of the securing clamp of the electronics compartment cover using an

Allen key (3 mm) and turn the clamp 90 ° counterclockwise.

2. Unscrew the electronics compartment cover and check the cover seal; replace it if

necessary.

5.9.2

Turning the display module

1.

2.

A0036401

1. Pull out the display module with a gentle rotational movement.

2. Turn the display module to the desired position: Max. 8 × 45 ° in each direction.

3. Feed the coiled cable into the gap between the housing and main electronics module

and plug the display module into the electronics compartment until it engages.