Precautions for handling

2.

● Do not use in explosive, flammable gas, or dusty atmospheres, any place where

water or oil may splash, and near combustibles. This may cause fire or injury.

● Do not perform any modification of the product.

Unpacking and Installation

3.

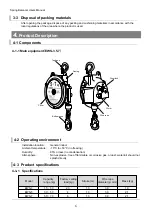

3-1 Packaging arrangement and transportation

3-2 Checks after unpacking

● Spring Balancer (main equipment) ---- 1 set

●

Support

S

ite guide

or Users Manual

--- 1 copy

Spring Balancer Users Manual

Emergency contact in case of malfunctions

If any problem with the product arises, contact us or your dealer.

Service engineer

The management supervisor is required to have sufficient knowledge of the product

and advanced operating skill for this product.

The management supervisor should manage not only the product itself but on-site

operations that handle the product, comprehensively.

In The service engineer is a worker with special knowledge and skills for installing the

product, investigating the causes of a failure or damage, and performing repairs

and overhauls. Service engineering (the work by the service engineer) is performed

by our service technicians or authorized service technicians.

Management

supervisor

Incorrect handling of this product may cause damage to the product itself as well as a fire or injury.

Thoroughly read the following precautions and be sure to heed the instructions when handling the

machinery.

The maintenance should be performed by a maintenance operator who has

developed sufficient knowledge and operating skill for the balancer.

● Incorrect usage of the product may cause an injury. Use the product correctly in

accordance with the descriptions in this manual.

● Particularly, “WARNING”, “CAUTION”, and “NOTICE” described in this manual

must be fully understood and always observed.

● Install the product correctly in accordance with the descriptions in this manual.

● Be sure to perform daily and periodic inspections.

● Be sure to use the product within the capacity range that is described in “4-3-1

Specifications”.

The standard set of this product is packaged for delivery in a cardboard box.

The total weight of the package is the sum of the weight described in “4-3-1 Specifications” and the

weight of the packing materials (approximately 0.5 kg).

When transporting the package, do not drop or allow impact to it.

Prepare a box of a similar size for re-packaging.

After opening the package, check that the following products are included.

Please contact us if you find anything missing or damaged.

5

WARNING

CAUTION