10

4

5

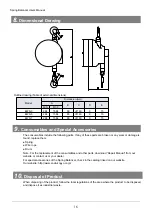

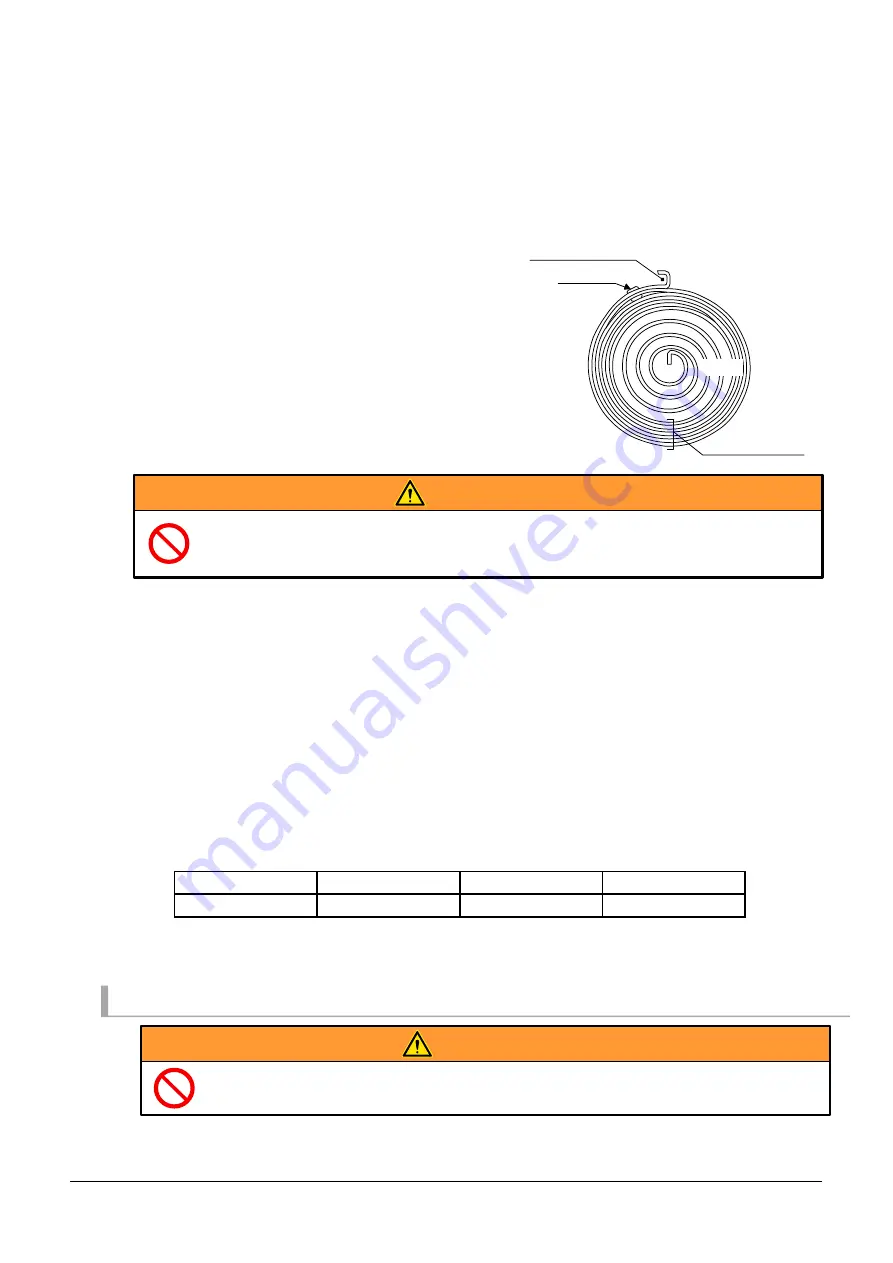

Fig.2

6

7

8

9

10

11

12

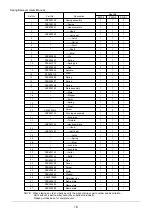

Model

EWS-3

100

EWS-5

55

EWS-7

55

Table-1

Spring Balancer Repair Manual

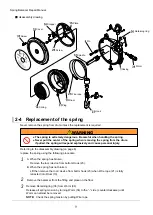

Turn Worm (34) further and remove it.

Remove Plug (31), and remove Wire rope (21)

from Drum (13).

Loosen Screws (33) and remove Cover (32).

Remove Drum (13) and Spindle (12) together from Casing (1).

Then remove Spindle (12) from Drum (13).

Loosen Screws (20) and remove Plate (15) from

Drum (13).

Check where is the broken portison of spring (14).

Check that the rivet of Spring (14) is not broken.

If Spring (14) is broken near the outer periphery

where there is no space between each turn

or the rivet of Spring (14) is broken (see Fig.2),

stop the replacement work.

Reassemble Plate (15) and contact the dealer.

Outer edge

Rivet

Near the outer

periphery

Inside

WARNING

Never remove Spring (14) from Drum (13) when Spring (14) is broken near the outer

periphery or the rivet of Spring is broken (see Fig.2).

If removed, Spring (14) will expand explosively and cause personal injury.

Remove Spring (14) from Drum (13).

Reassemble in reverse order.

● First install Spring (12) and Drum (13) in Casing (1), then install Spring (14) into Drum (13).

● After assembling new Spring (14), lubricate Spring (14) with grease.

● When installing Plate (15) on drum (13), place Stopper (16) in the outer edge of Spring (14).

Check Stopper (16) can move smoothly after installing Plate (15).

Wind Spring (14) by turning Worm (34) to the “ + ” side (clockwise).

While turning Worm, Wire rope (21) will be retracted into Drum (13). Pay attention

Wire rope does not slip out from the drum groove.

NOTE:

After Wire rope is fully retracted, turn Worm by the number of turns shown in Table1.

Number of turns

NOTE:

Numbers above are for the middle value of

the capacity range.

2-5 Spring disposal

The spring is dangerous due to remaining tension even if it is broken.

Give a warning to disposal companies that the spring will expand explosively and cause danger if

the spring is treated roughly or the center of the spring is pulled.

WARNING