- 17 -

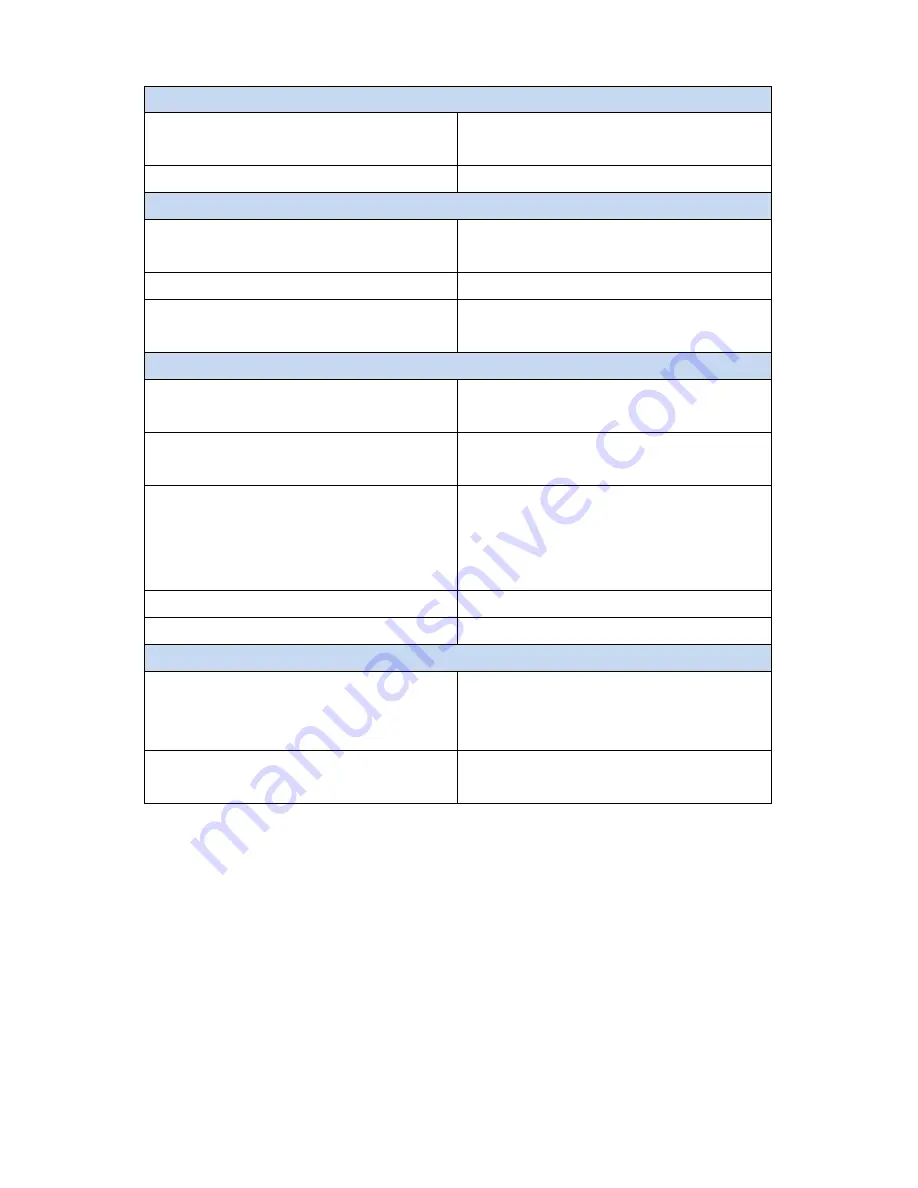

LIGHT PRINT IMAGES

Low print head darkness or

excessive print speed

Perform a Default Settings Reset

(see Section 4.4)

Foreign material on print head

Clean print head and platen roller

UNEVEN PRINT DARKNESS

Damaged or worn platen roller

Contact En-Vision America for

support

Foreign material on print head

Clean print head and platen roller

Defective print head

Contact En-Vision America for

support

SMEARED PRINT IMAGES

Wrong labels used

Be sure ScripTalk 10kb labels are

being used (PN 00210-10K-250)

Foreign material on print head

and/or platen roller

Clean print head and platen roller

Foreign material on labels

Clear foreign material from

labels, if possible; otherwise,

advance label roll until foreign

material is no longer present

Excessive print head energy

Excessive print speed

MEANDERING MEDIA

Incorrectly loaded media

Ensure media holder and guides

are set properly, then reload

media

Damaged or worn platen roller

Contact En-Vision America for

support