40946-0-1019

Page 16

DVB-1 For Direct Vent Wall Furnaces DV210 and DV215

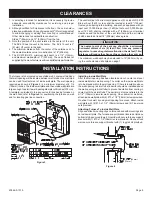

INSTALLING OPTIONAL BLOWER DVB-1. The blower must be

positioned as shown in Figure 1. Relocate gas line, if necessary,

using elbow fitting at the gas valve, and move Piezo Spark Genera

-

tor to the next screw. A slot on the bottom of the blower package

engages a tab on the bottom of the inner casing and is secured by

one screw in front.

BLOWER

MOUNTING

TAB

Figure 1

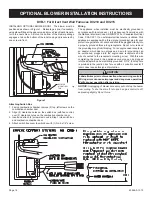

Attaching Switch Box

1. Facing combustion chamber, remove (2) top, left screws on the

combustion chamber door.

2. Align (2) clearance holes on the switch box (with fan control)

over (2) clearance holes on the combustion chamber door.

3. Insert and attach (2) screws removed in Step 1 into switch box

and combustion chamber door.

4. Attach switch box cover to switch box with (1) No. 8 x 1/4" screw.

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

Wiring

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical

Code, CSA C22.1, if an external electrical source is utilized. This

appliance is equipped with a three-prong [grounding] plug for your

protection against shock hazard and should be plugged directly into

a properly grounded three-prong receptacle. Do not cut or remove

the grounding prong from this plug. For an ungrounded receptacle,

an adapter, which has two prongs and a wire for grounding, can

be purchased, plugged into the ungrounded receptacle and its

wire connected to the receptacle mounting screw. With this wire

completing the ground, the appliance cord plug can be plugged

into the adapter and be electrically grounded. A 7/8" (22mm) hole

is provided in the junction box for use with a conduit connector if

local codes require this type of protection.

CAUTION

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

NOTICE:

Unplugging of blower accessory will not stop the heater

from cycling. To shut heater off, turn knob on gas control to off,

depressing slightly. Do not force.