TB-6520

Page 4 of 7

Test Lab Test Procedure Guideline

For test lab use of ESD Worksurfaces, Floor Materials,

Footwear, Garments, or Seating, best advice is to follow

procedures in applicable ESD Association standards (see

above) which include details regarding:

• Cleaning (For example per S4.1 “The test specimens and

electrodes shall be cleaned twice with a minimum 70%

isopropanol-water solution using a clean, low-linting cloth

each time). Allow to dry.

• Environmental chamber (For example per S4.1 control

relative humidity to 12 ±3% RH and 50 ±5% RH and

temperature to 23 ±1 degrees C)

• Specimen support surface (For example per S4.1

greater than 1.0 x 10E12 ohms such as PMMA, PTFE or

polycarbonate)

• Specimen Pre-Conditioning (For example per S4.1 at 23

±1 degrees C; 3 specimens at 12 ±3% relative humidity

for 72 hours minimum, and 3 specimens at 50 ±5%

relative humidity for 72 hours minimum)

• Reporting Test Results, for example per S4.1 Reporting

Test Results, Report:

• Minimum, median and maximum readings for both

resistance-to-groundable point and point-to-point

resistance in ohms at low relative humidity

• Minimum, median and maximum readings for both

resistance-to-groundable point and point-to-point

resistance in ohms at moderate relative humidity

• Temperature

• Relative humidity

• Actual duration of conditioning

• Test equipment used

Periodic Checks of Installed Product Test

Procedure Guideline

The ESD Association lists test procedures and

troubleshooting tips in Compliance Verification ESD TR53.

We recommend this document be purchased from

Measure RTG Resistance to Ground

Test Procedure in reference with ANSI/ESD S4.1 section

6.4 Periodic Worksurface Testing:

• Do not clean the surface

• Remove from the surface only those items that might

interfere with the test.

• ESD sensitive devices shall also be removed

• The black sensing test lead with shielded plug should go

to equipment ground or a groundable point

• Use one Electrode on other test lead and place Electrode

the farthest convenient point on the surface

• Press button and hold Test Button until measurement is

displayed

• Perform additional measurements placing Electrode on

the most commonly used or most worn area

If measurement is outside acceptable limits, clean surface

and retest to determine if cause of failure is insulative dirt

layer or the ESD contol item. Note: Use an ESD cleaner

containing no insulative silicone.

Measure RTT Resistance Between Two Points

on the Surface

• Do not clean the surface

• Remove from the surface only those items that might

interfere with the test.

• ESD sensitive devices shall also be removed

• Use two 5 Pound Electrodes, place in the most commonly

used portion of the surface 10" apart (2" from any edge,

3" from any groundable point) for worksurface and 3' for

flooring

• Press Test button and hold Button until measurement is

displayed

• If the most used portion is not obvious, use two points

near the center of the surface

If measurement is outside acceptable limits, clean surface

and retest to determine if cause of failure is insulative dirt

layer or the ESD contol item. Note: Use an ESD cleaner

containing no insulative silicone.

© 2010 DESCO INDUSTRIES INC.

Employee Owned

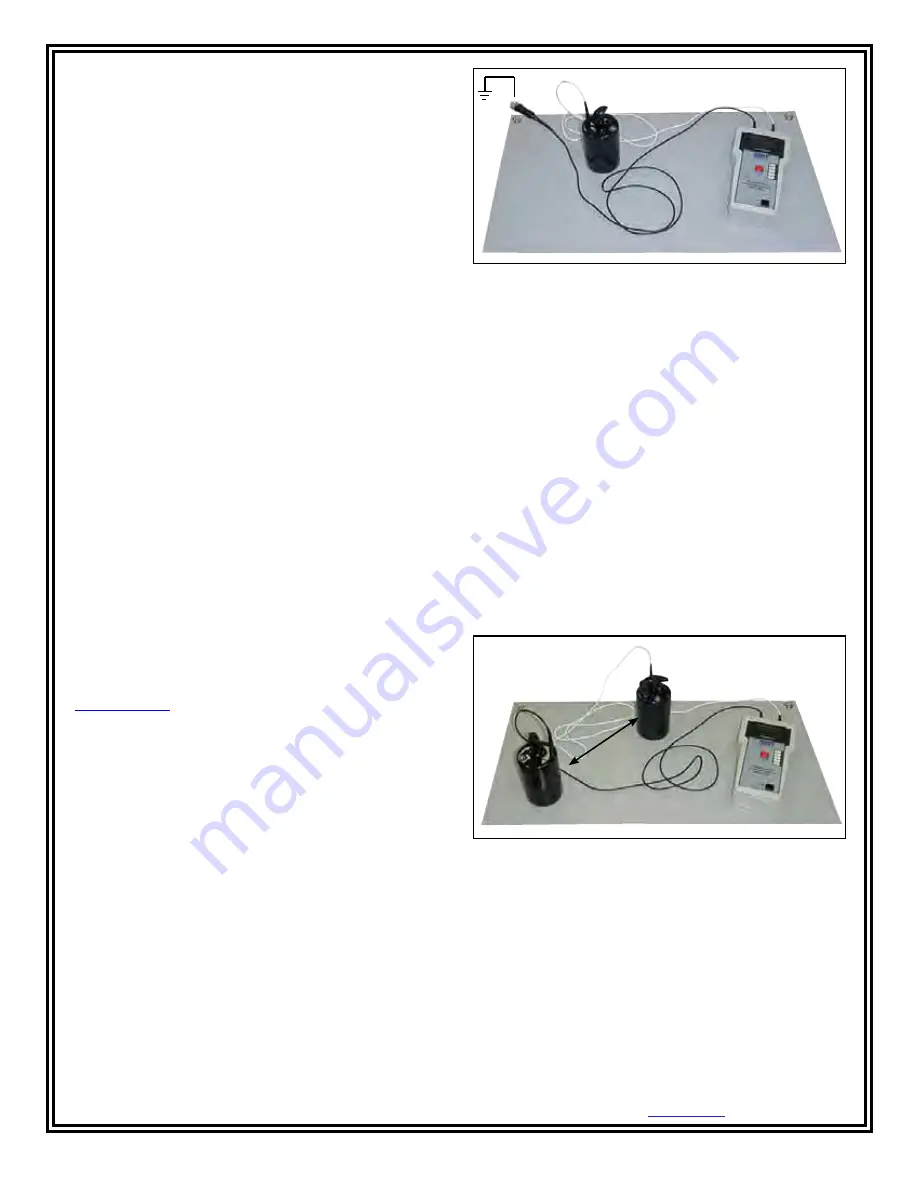

Figure 3. Setting up for RTG testing.

10”

Figure 4. Setting up for RTT testing. (Electrodes are to be

about 10" apart for worksurfaces and about 3' for flooring)

Reporting and Using Test Results

Different standards have different requirements; use

requirements as specified in user’s ESD control plan.

Examples are:

Per ANSI/ESD 4.1 (worksurfaces), Report:

• RTG maximum and minimum values measured for

resistance-to-ground

• RTT maximum and minimum values measured for

point-to-point resistance in ohms

EMIT

- 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: