Type BM9

13

To change pilot-loaded slam-shut controller setpoints

(overpressure and/or underpressure), adjust the

pilot setpoints. Refer to pilot’s instruction manuals

for details.

Monitor outlet pressure with a test gauge during

the adjustment.

Range Setting

The reset differential indicates the minimum value to

be considered with respect to downstream pipeline

pressure set point for proper resetting of the controller.

See Figure 12.

Example: Downstream pipeline pressure set point

15 bar / 218 psig.

Choose OS9/84X-R with blue spring for overpressure

and red spring for underpressure, see Tables 7 and 8.

The reset differential ∆Pwo is 3.0 bar / 43.5 psig and

∆P

wu

is 6.0 bar / 87.0 psig.

So, the overpressure set value should be

18 bar / 261 psig (15 bar + 3 bar = 18 bar or

218 psig + 43.5 psig = 261 psig) or higher, and

underpressure set value should be 9 bar / 131 psig

(15 bar - 6 bar = 9 bar or 218 psig - 87 psig = 131 psig)

or lower.

Shutdown

▲

WARNING

To avoid personal injury resulting from

sudden release of pressure, isolate the

slam-shut valve from all pressure before

attempting disassembly and release

trapped pressure from the equipment

and pressure line.

△

CAUTION

In any installation, it is important to

slowly open and close the valves and to

vent the outlet pressure before venting

the inlet pressure to prevent damage

caused by reverse pressurization of the

pilot or main valve.

1. Slowly close the valves in the following order:

a. Inlet block valve

b. Outlet block valve

c. Control line valve(s), if used.

2. Open the vent valves to depressurize the system.

Maintenance

▲

WARNING

To avoid personal injury resulting

from sudden release of pressure,

isolate the slam-shut valve from the

system pressure and release trapped

pressure from the equipment and

pressure line before attempting

maintenance operation.

Use proper lifting techniques, when

lifting the body and spacer (keys 1

and 17).

The optional drainage plug at the bottom

of the valve, shown in Figure 13, must

not be removed unless the pressure

in the valve is completely released.

If violated, serious injury may occur

due to sudden release of extremely

high pressure.

The slam-shut valve parts are subject to normal wear

and must be inspected periodically and replaced

as necessary. The frequency of inspection and

replacement depends on the severity of service

conditions and on applicable federal, state and local

codes and regulations.

Use Torque Specifications

(Table 5) for proper torque values.

Main Valve (See Figures 14, 15 and 16)

▲

WARNING

Installation, operation and maintenance

procedures performed by unqualified

personnel may result in improper

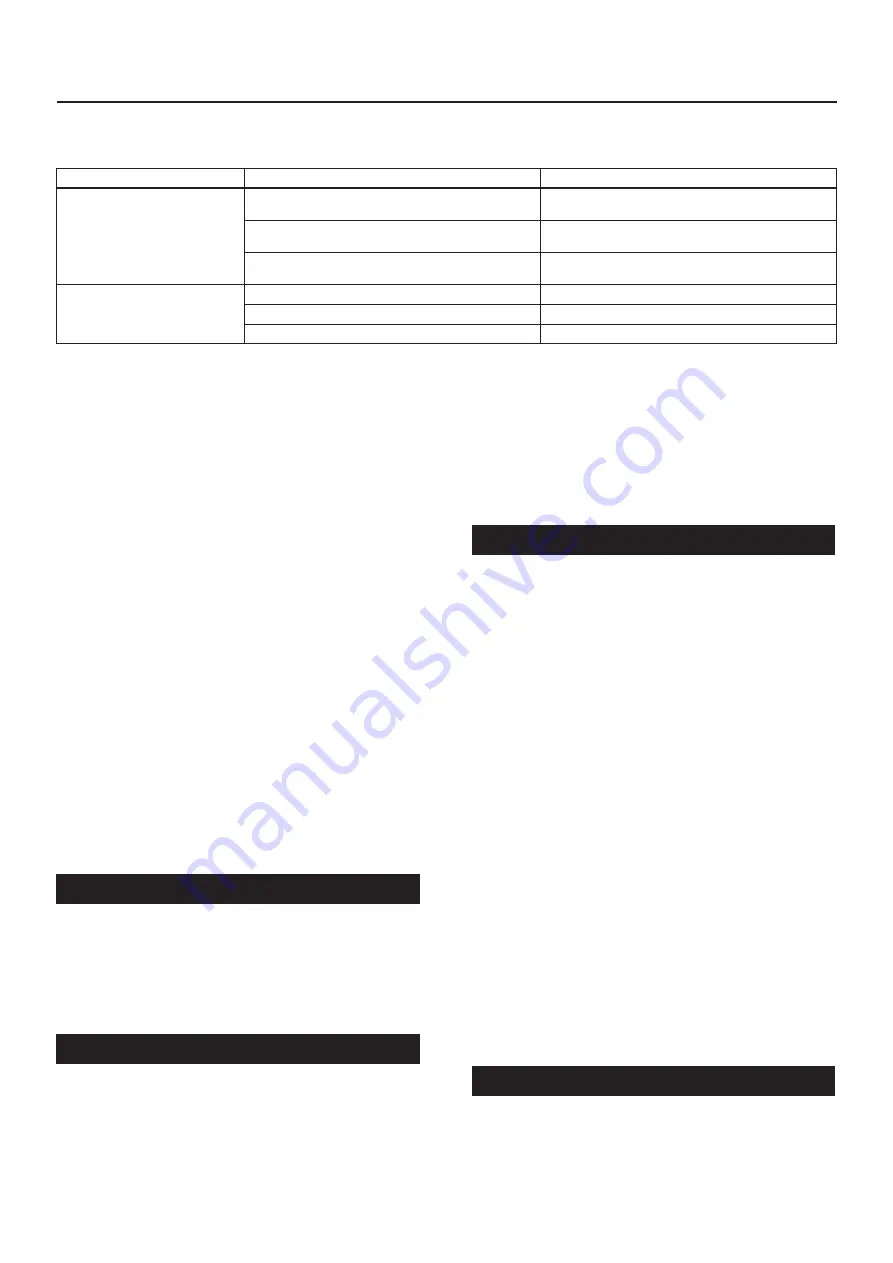

Table 6.

Troubleshooting Type BM9 Slam-Shut Valve

SYMPTOMS

CAUSE

ACTIONS

Slam-shut device does not remain set

The sensing line to port (A) of slam-shut controller

is not connected properly

Check the sensing line connections (A)

Downstream pressure coincides with

the maximum or minimum slam-shut settings

Check slam-shut controller settings

Damaged Diaphragm (key 62) on Type OS9/80X-R

Lip seal (key 66) on Types OS9/84X-R and OS9/88X-R

Replace the diaphragm on Type OS9/80X-R

Replace the lip seal on Types OS9/84X-R and OS9/88X-R

Sleeve does not seal properly

Worn seal gaskets

Check gaskets and replace if necessary

Dirt deposit on sleeve

Check sleeve and clean / replace if necessary

Shaft and Roller (keys 7 and 50) are damaged

Check shaft and roller and replace if necessary