7

10 DISPOSAL AT END OF USEFUL LIFE

Penberthy illuminator’s metal and polymers

should be recycled whenever possible. Refer

to order and Penberthy’s material specification

sheets for materials of construction.

12 TELEPHONE ASSISTANCE

If you are having difficulty with your illuminator,

notify your local Penberthy distributor. You may

also contact the factory direct at (956) 430-2500

and ask for an applications engineer. So that

we may assist you more effectively, please

have as much of the following information as

possible when you call:

∙ Model #

∙ Name of the company from whom you

purchased your illuminator

∙ Invoice # and date

∙ Operating temperatures

∙ A brief description of the problem

∙ Troubleshooting procedures that failed

If attempts to solve your problem fail, you may

be requested to return your illuminator to the

factory for intensive testing. You must obtain

a Return Authorization (RA) number from

Penberthy prior to returning anything. Failure

to do so will result in the unit being returned

to you, without being tested, freight collect. To

obtain a R.A. number, the following information

(in addition to that above) is needed:

∙ Reason for return

∙ Person to contact at your company

∙ 'Ship-to' address

There is a minimum charge for evaluation

of non-warranty units. You will be contacted

before any repairs are initiated should the cost

exceed the minimum charge. If you return a

unit under warranty, but is not defective, the

minimum charge will apply.

9 PACKAGING, STORAGE AND

TRANSPORTATION

9.1 Packaging

The LED illuminator contains fragile

components and must be handled with care.

These units must be packed to prevent damage

during transportation. If damage to the glass

should occur during shipment contact the

factory.

9.2 Storage

The LED illuminator can be stored outside.

These units are not affected by temperature or

humidity.

11 WARRANTY

See sales order acknowledgements for terms

and conditions of sale.

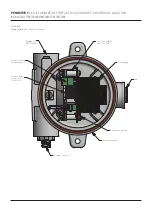

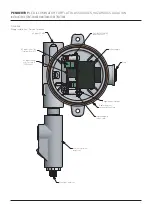

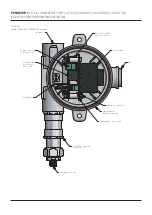

8.2 Reassembly

Refer to the exploded parts diagram in

Sections 13-15 for additional reference during

disassembly and reassembly of the illuminator.

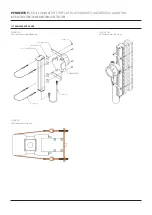

Transparent gauge

1. Position the illuminator on the gauge so that

the top end cap of the illuminator rests on

the top end of the gauge cover.

2. Position the mounting brackets with wires

where desired and wrap wire around the

gauge. Insert other eyebolt on opposite side

of attachment plate.

3. Center the illuminator and firmly tighten

down the wire to hold the illuminator to the

gauge.

4. Connect electrical power source to the

illuminator.

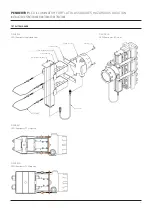

Reflex gauge

1. Replace the screws on the back of the LED

illuminator body.

2. Illuminator should be centered with respect

to the vision slot of the gauge. Tighten

screws to secure illuminator to the bracket.

3. Connect electrical power source to the

illuminator.

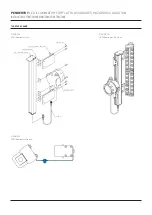

TSL/TSM gauge

1. Position the illuminator on the gauge so that

is centered with respect to the vision slot of

the gauge.

2. Wrap the SAS wire around the gauge and

the TSL/TSM mounting bracket (place wire

rope through the tabs on the bracket to

keep it straight) . Insert the other eyebolt on

the opposite side of the plate bracket and fix

with the nut/wing-nut provided.

3. Center the illuminator and firmly tighten

down the wire assembly to hold the

illuminator to the gauge.

4. Connect electrical power source to the

illuminator.

PENBERTHY

LED ILLUMINATOR FOR FLAT GLASS GAUGES, HAZARDOUS LOCATION

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

9.3 Transportation

Since the LED illuminator contains fragile

parts, care should be taken to ensure that

the unit arrives undamaged. After unpacking

unit, it should be inspected and any damaged

parts should be replaced before assembly and

installation.