7

PENBERTHY

SERIES LC FLAT GLASS GAGES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

8 REMOVAL - DISASSEMBLY - REASSEMBLY

WARNING

Use only qualified, experienced personnel who

are familiar with liquid level gage equipment and

understand the implications of the tables and

all the instructions thoroughly. DO NOT proceed

with any maintenance unless the liquid level gage

has been relieved of all pressure or vacuum, has

been allowed to reach ambient temperature and

has been drained or purged of all fluids. Failure

to follow instructions can cause serious personal

injury and property damage.

7.2 Troubleshooting

Problem: Glass becomes etched or clouded

prematurely in service.

Cause:

Fluid being handled is not

compatible with the glass or shields.

Solution: Replace the glass and install

shields which will not be affected

by contained fluid.

Problem: Glass breaks continually in

service despite careful attention

to maintenance procedures.

Cause:

Thermal shock, hydraulic shock,

mechanical loads, exceeding design

ratings or a combination of these.

Solution: Check entire system to determine

possible sources of loads. Check

application to determine actual

operating conditions and contact an

authorized Penberthy distributor on

how to proceed.

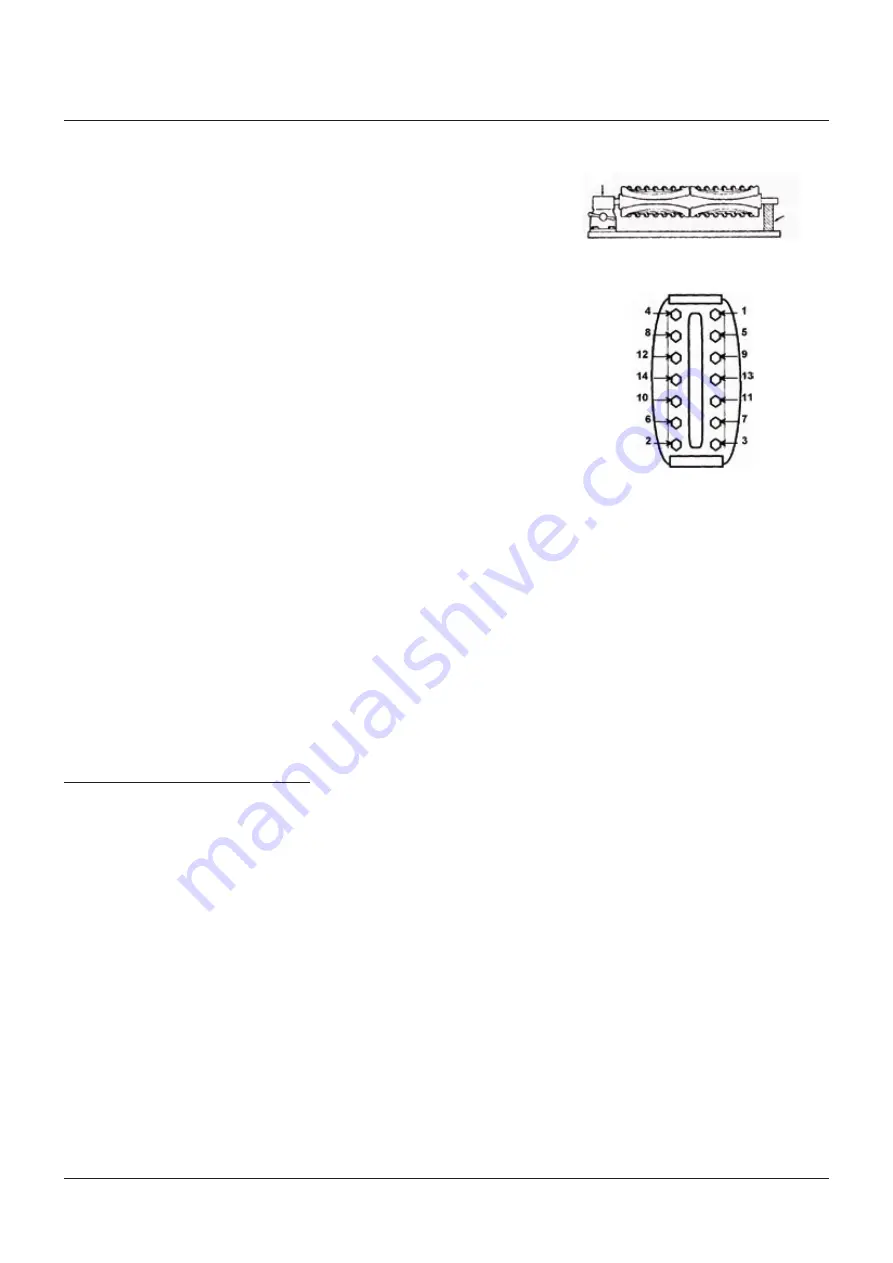

FIGURE 3

FIGURE 4

Nut loosening sequence

8.1 Disassembly

Secure a workbench, equipped with a vise at

one end, longer than the liquid level gage and

sufficiently wide to lay out parts as they are

removed. Attach and tighten a nipple to each

end connection to serve as temporary means

of supporting the liquid level gage during

disassembly and reassembly.

1. Grip nipple on one end with vise and hold up

the other end with a 2 x 4 or suitable prop as

shown in Figure 3.

2. Hold gage firmly; loosen nuts starting

at both ends of each section and then

proceeding from both ends to the center

of each section as shown in Figure 4.

3. Nut loosening sequence

- Remove nuts, washer, belleville washers

(if any) and nameplate.

- Tap covers with rubber hammer as needed

to loosen and remove.

- For belleville washer assemblies:

to remove covers, studs may need to be

removed by laying the assembly on its side

and knocking the stud/U-bolts through the

cover with a hammer and punch.

- Remove cushions, glass, shields (if any)

and gaskets.

- Tap liquid chamber or remaining covers as

necessary with rubber hammer to break

loose and remove remaining components.

- Remove, destroy and dispose of all glass,

cushions, gaskets and shields. Under no

circumstances should these components

be re-used or installed on a gage.

Note:

if size of gage is smaller than shown,

follow spiraling sequence from the ends until

all bolting is loosened.

WARNING

Once used, cushions, gaskets and shields are

deformed permanently by compression and, if

re-used, may cause leaks and high stress points

resulting in glass breakage. Glass may contain

hidden damage and internal stresses caused by

previous usage. If re-used, the glass may break

under pressure causing severe personal injury

or property damage.

Vise

Prop

Connection leaks

at a flanged or threaded

connection should be corrected by tightening

the bolting at the connection or by taking the

liquid level gage out of service and wrapping

the connection threads with PTFE tape on all

male pipe threads.

Corrosion

may occur if the user has selected

an improper material for the liquid level gage

application. It is the responsibility of the user to

choose a material of construction compatible

with both the contained fluid and the

surrounding environment. If internal or external

corrosion is present, an investigation must be

performed by the user immediately. It may be

necessary to contact an authorized Penberthy

distributor to better determine the origin of the

corrosion.