3

PENBERTHY

MODEL CTE MIXER / HEATER

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

4 INSTALLATION

Installation should only be undertaken by

qualified, experienced personnel who are

familiar with this equipment and have read and

understand all the instructions in this manual.

The user should refer to the relevant technical

data sheet or product proposal to obtain

dimensional information for the specific size

and model of CTE.

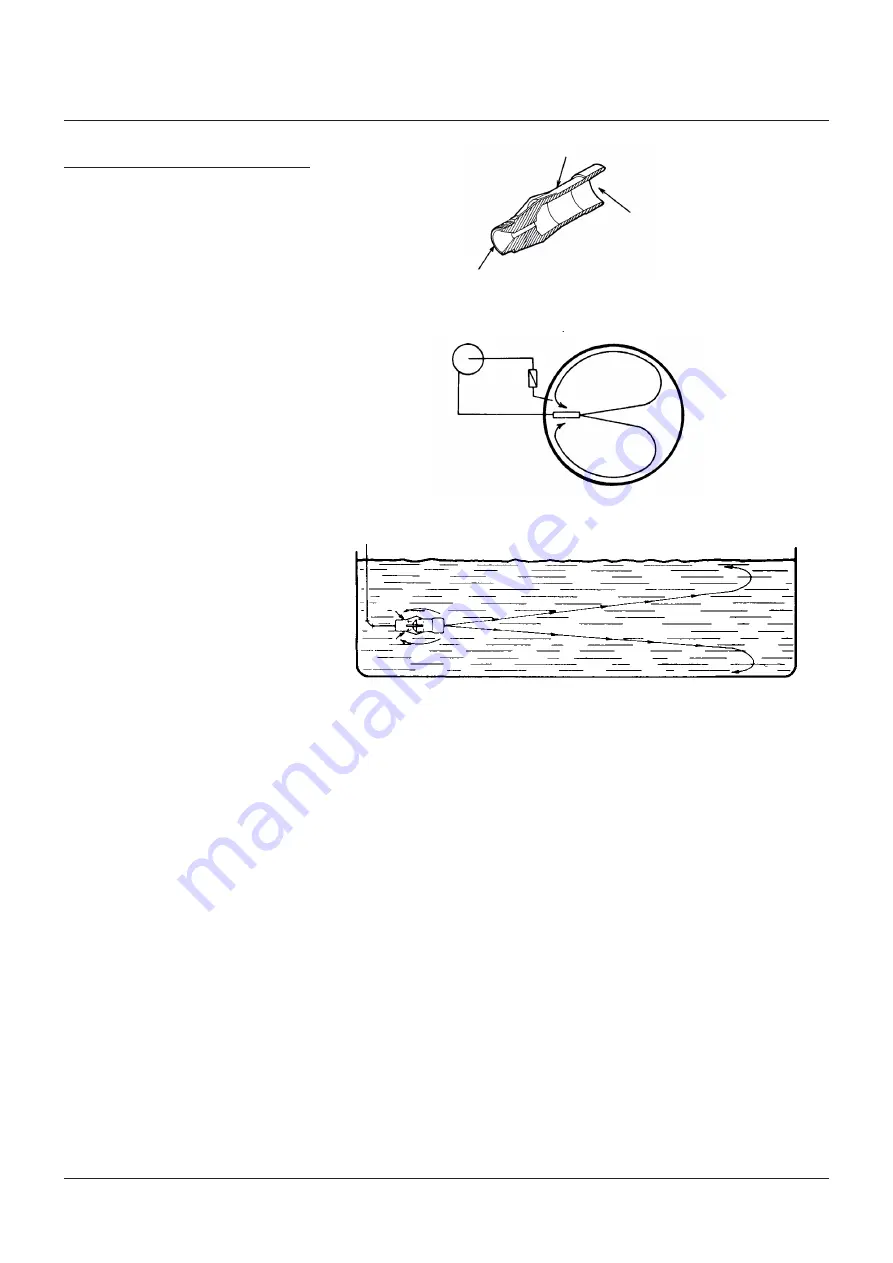

Check the cut-away view (Figure 1) for the

location of the threaded inlet.

4.1 Mounting

A CTE can be mounted in any position. The

supply line and manifold piping to multiple

CTEs must be sized to supply uniform pressure

to each CTE.

It is important that the CTE be positioned

within the tank so as to insure the free flow of

liquid to be mixed or heated into and out of the

unit(s). The greatest agitation occurs within the

discharge plume; therefore, the discharge end

should be aimed towards the most remote part

of the tank. On the other hand, the intake end

of the unit must be far enough from the tank

corner or wall to allow the free flow of liquid

into the suction openings.

Tank shape and size influence the placement

and number of CTEs required to maintain even

agitation or temperature distribution. With a

spherical tank, a single CTE mounted as shown

in Figure 2 makes the best use of the mixing

and heating characteristics of the CTE. With

no corners to impede liquid flow, the liquid

circulates evenly and undisturbed.

In a cylindrical, square or rectangular tank, the

angular intersection of surfaces can interrupt

liquid flow patterns and cause liquid stagnation

in these areas. A single CTE mounted as shown

in Figure 3 will minimize this. Whenever the

ratio of length to diameter of the tank is greater

than 2:1 (such as tank trucks or railroad cars),

it is recommended that multiple CTEs be used.

FIGURE 1

FIGURE 2

Discharge

Inlet

Spherical

Body

4.2 Effect of related piping and precautions

1. For mixing

a. Operating liquid supply line pressure loss

must be taken into account when applying

CTEs.

b. Supply line must be clean and should be

provided with a strainer to prevent foreign

materials from clogging the mixer.

c. CTEs must be fully submerged to prevent

liquid from splashing and drawing

atmospheric air, and to promote maximum

mixing.

d. Clearance should be provided for removal of

the CTE.

e. Provisions should be made for a pressure

gauge connection at or near the CTE

inlet. It may become necessary to install a

pressure gauge if operating difficulties are

encountered.

f. Inlet piping must be secured to the tank wall

near the CTE to keep strain off piping when

in operation.

g. Supply line and manifold piping must be

sized to supply adequate pressure equally to

each CTE when multiple CTEs are used.

2. For heating

a. Steam must not have more than 20°F (-7°C)

of superheat or performance will differ from

that published in the relevant technical

data sheet or product proposal referred to

previously.

b. Steam line pressure loss must be taken into

account when applying CTEs.

c. The steam line must be clean and should be

provided with a strainer to prevent foreign

materials from clogging heater.

d. The steam line must be insulated and as

short as possible to prevent condensation

and friction losses.

e. CTEs must be fully submerged to prevent

liquid from splashing and to promote

condensation.

f. Clearance should be provided for removal of

the CTE.

g. Provisions should be made for a pressure

gauge connection at or near the CTE

inlet. It may become necessary to install a

pressure gauge if operating difficulties are

encountered.

h. Steam piping must be secured to the tank

wall near the CTE to keep strain off piping

when in operation.

i. The steam supply valve must be a quick

opening type installed as close to the CTE as

practical.

FIGURE 3