2

KEYSTONE

OPTISEAL F14/16 - 15/17 AND BREWSEAL BUTTERFLY VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3 INSTALLATION

WARNING!

For safety reasons, it is important to take the

following precautions before you start work on

the valve:

1. Personnel making any adjustments to

the valves should utilize suitable equipment.

All required personal protection means

should be worn.

2. The line must be depressurized before

installing the valve.

3. Installation and handling of valves should be

done only by personnel that is trained in all

aspects of manual and mechanical handling

techniques.

4. Misuse of the valve is not allowed.

For example: the valve, handles, actuators or

other parts may not be used as ‘climbing tools’.

5. Ensure that valve pressure/temperature

limitations marked on the identification tag

are within the service conditions. The trim

number on the valve’s tagplate identifies

the valve materials. See Product Manual for

valve specific P/T diagram and trim number

definition.

6. Ensure that valve materials are compatible

with the pipeline fluid.

7. For DVGW-Gas approved lugged valves,

through threaded rods must be used instead

of flange bolts.

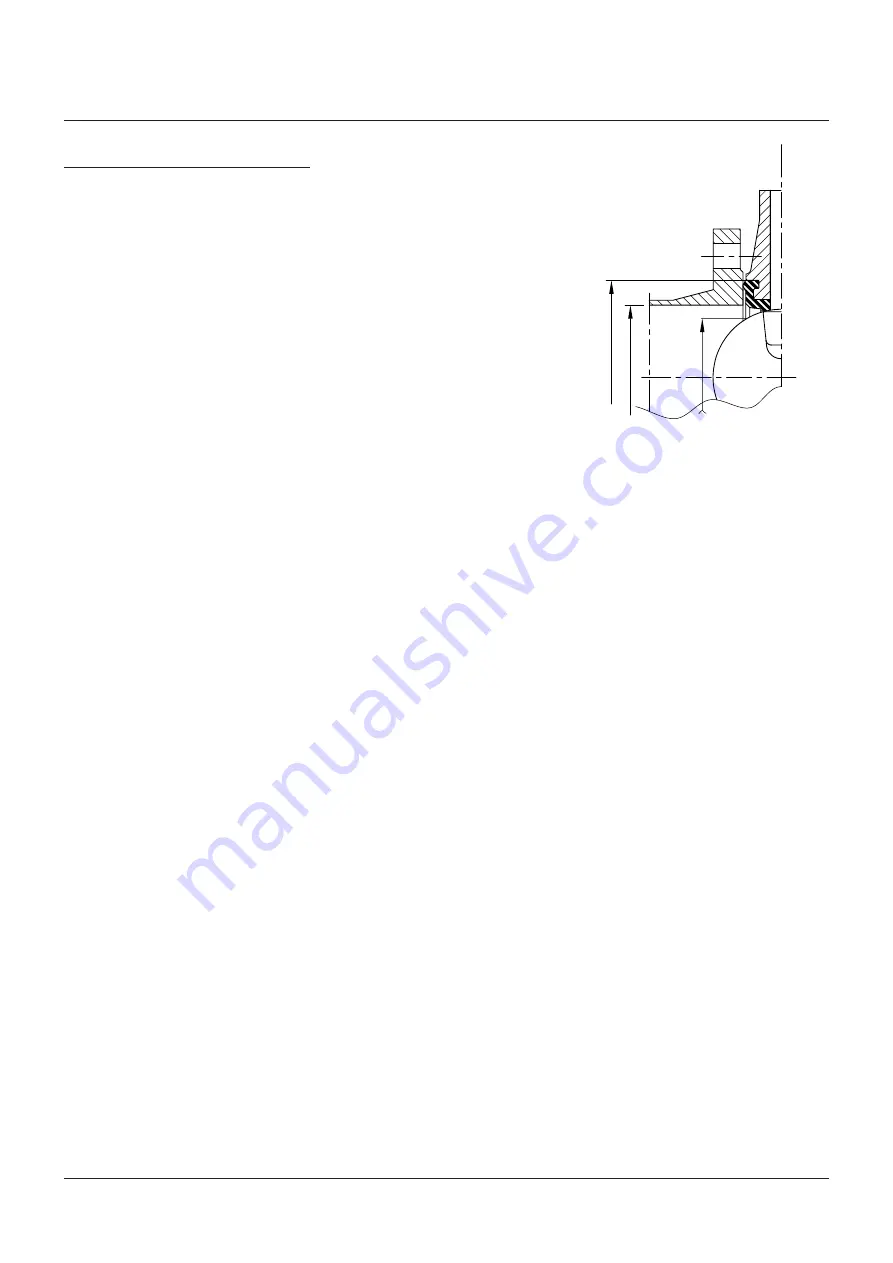

YY

D max./min.

Q

3.1 Visual valve inspection

1. Confirm that the materials of construction

listed on the valve nameplate are

appropriate for the service intended and

are as specified.

2. Tag/name plate identification

Manufacturer:

Keystone

Fig.:

e.g. OptiSeal 14-112

JOB:

Job number

Nominal size:

DN

M.P.W.P.:

maximum permissible

working pressure

Flange compatibility: e.g. PN 10/16

Temperature:

e.g. -40/120°C

Body:

e.g. GJL 250.

3.2 Flange and pipe compatibility

Check matching of flange drilling pattern

of valve and pipe before assembly.

Flanges have to meet the following

requirements:

- The face inside diameter should be:

D min.: the valve Q-dim adequate

disc clearance.

D max.: the optimum inside diameter (ID)

is equal to the inside diameter of flange

standard EN 1092-1, table 8, type 11.

For larger than D max inside diameters or

other flange types please contact your local

Emerson Sales organization, as larger inside

diameters might result in reduced valve

functionality.

Do not use flange gaskets, these lead to

valve damage!

3.3 Valve installation

The valves are bi-directional and may be

fitted in either direction relative to the flow.

The valve will control flow equally in either

direction. The recommended installation

position is shaft horizontal and the lower disc

edge opening down-stream. (Especially for

slurry service and media with a tendency for

sedimen tation). For optimum valve control and

smooth performance, it is recommended to

have a 10 to 20 pipe diameters of straight run

inlet piping and 3 to 5 pipe diameters straight

outlet piping.

A valve is no crow-bar. Do not use the valve

to spread the flanges. Seat damage might be

the result.

- If the flange (or pipe) is provided with a

raised face, the diameter of this shall be at

least 8 mm larger than the YY-dimension of

the valve.

The use of the flange-gaskets is not allowed

since it might damage the valve.

The Keystone seat-face design eliminates

the need for the gaskets.

Use flange bolting in agreement with

appropriate standard.