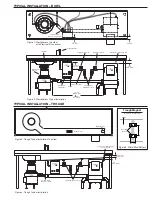

TYPICAL INSTALLATION – BOWL

TYPICAL INSTALLATION – TROUGH

Figure 1. WasteXpress Top View

with Electrical Connections

Flow Control Valve

WasteXpress

Disposer

Sink Bowl

Syphon Breaker

Cold Water Solenoid

Hot Water Solenoid WasteXpress Dewatering Unit

Shut Off Valve

(supplied by others)

1-1/2" min

(38.1 mm

min)

1" min

(25.4 mm min)

45˚ bend shown

(max of 4 can be used)

3"

(76.2 mm)

1-1/2"

(38.1 mm)

Figure 2. WasteXpress Typical Installation

WasteXpress

Control Panel

10 max

(3.1 m max)

18" min

(0.46 m min)

Power

Trough Flow

Water Nozzle

Recommended

Magnet Location

Optional Magnet Location

Connect Cold Water Supply

1" min

(25.4 mm min)

1" (25.4 mm) min,

3" (76.2 mm) max

to end of Trough

Figure 4. Trough Typical Installation

Figure 3. Trough Typical Installation Top View

Trough

Trough

Optional Magnet Location

Recommended Magnet Location

Mounting

Brackets

6"

2–3/8"

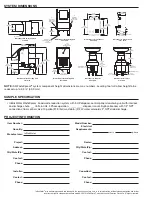

Figure 1: Viewing From Bottom

Figure 2: Trough Magnet Positions

Trough Silver Saver Kit

(#13983)

Part No. 13986 January 2008

Installation Instructions

1. Determine best place for magnet(s)

(See Figure 2).

2. Place magnet on underside of trough with

magnetic pull toward sink bowl.

3. Place one mounting bracket over each end

of magnet (See Figure 1). Shoot weld studs

and secure mounting brackets with nuts.

NOTE:

Trough magnets should be placed

within 12" from end of trough or

intersection of trough and sink bowl.

NOTE:

Additional magnets should

be evenly spaced over remaining

trough area.

Trough Magnet

As Viewed From Bottom

Figure 5. Weld Stud Pattern