Y692VB Series

2

!

WARNING

Personal injury, equipment damage

or leakage due to escaping fluid or

bursting of pressure-containing parts

may result if this vacuum breaker is

overpressured or is installed where

service conditions could exceed the

limits given in the Specifications

section or where conditions exceed

any ratings of the adjacent piping or

piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by the appropriate

code, regulation or standard) to

prevent service conditions from

exceeding limits.

Additionally, physical damage to the

vacuum breaker could result in personal

injury and property damage due to

escaping fluid. To avoid such injury and

damage, install the vacuum breaker in a

safe location.

Clean out all pipelines before installation of the

vacuum breaker and check to be sure the vacuum

breaker has not been damaged or has collected

foreign material during shipping. For NPT bodies,

apply pipe compound to the external pipe threads.

For flanged bodies, use suitable line gaskets and

approved piping and bolting practices. Install the

vacuum breaker in any position desired, unless

otherwise specified, but be sure flow through the body

is in the direction indicated by the arrow on the body.

Startup

The vacuum breaker is factory set at approximately

the midpoint of the spring range or the pressure

requested, so an initial adjustment may be required

to give the desired results. With proper installation

completed and vacuum breakers properly adjusted,

slowly introduce inlet pressure. The unit takes

control when vacuum is established. This equipment

is suitable for the vacuum control pressure range

stamped on the nameplate.

Adjustment

To adjust the pressure setting, remove the closing cap

and turn the adjusting nut clockwise to increase the

pressure setting or counterclockwise to decrease the

setting. Replace the closing cap after adjustment. The

closing cap may be wired to the hole provided in the

spring case to discourage tampering.

Taking Out of Service (Shutdown)

To avoid personal injury resulting from

sudden release of pressure, isolate the

vacuum breaker from all pressure before

attempting disassembly.

To shut down the unit, close the upstream shut-off

valve, and then close the downstream shut-off valve to

vent the equipment properly. Next, open the vent valve

between the equipment and the downstream shut-off

valve nearest to it. All pressure between these shut-off

valves is released through the open vent valve.

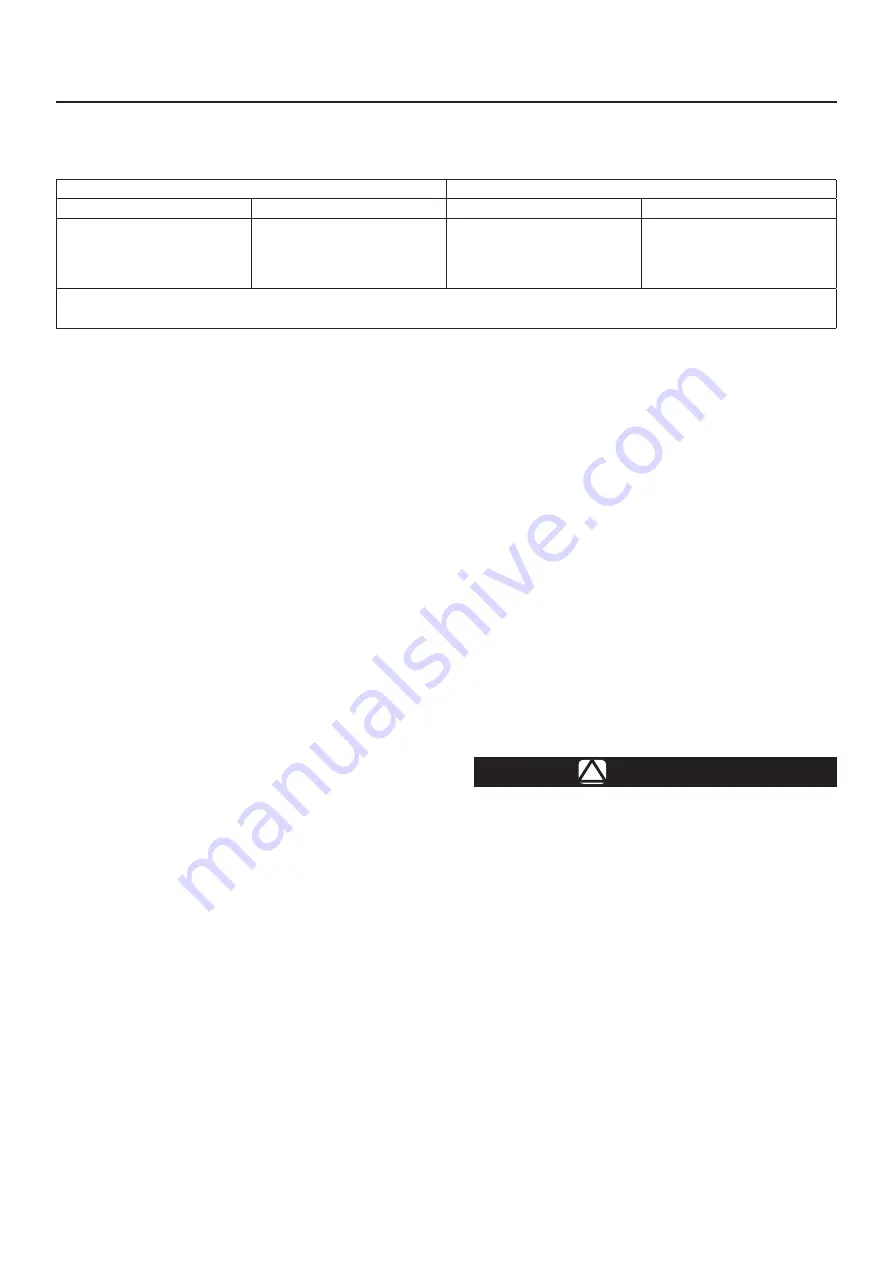

Table 1

. Vacuum Pressure Information

VACUUM CONTROL PRESSURE RANGE

(1)

CHANGE IN VACUUM CONTROL PRESSURE TO REACH WIDE-OPEN

mbar

in. w.c.

mbar

in. w.c.

2 to 7

(2)

7 to 20

(2)

20 to 40

40 to 80

17 mbar to 0.21 bar

1 to 3

3 to 8

8 to 16

16 to 32

0.25 to 3 psig

3

10

13

26

0.14 bar

1.2

4.0

5.0

10.5

2 psig

1. Pressure ranges are based on the spring case pointing up. Pointing the spring case down increases the pressure range 4 mbar / 1.7 in. w.c..

(Example: 2 to 7 mbar / 1 to 3 in. w.c. changes to 7 to 12 mbar / 2.7 to 4.7 in. w.c..

2. Do not use fluorocarbon (FKM) with these springs at diaphragm temperatures lower than 4°C / 40°F.