Instruction Manual

D103553X012

Large ET and ED Valves

July 2017

4

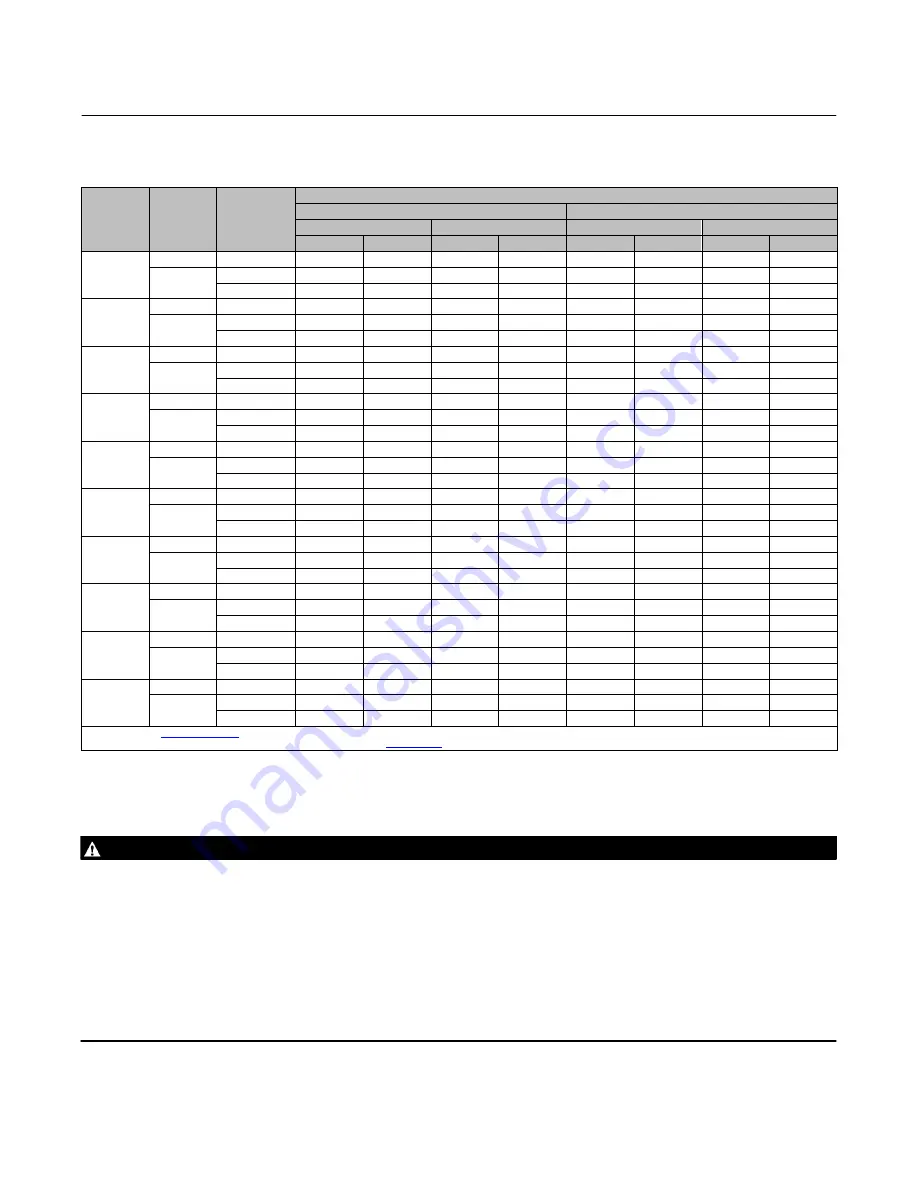

Table 2. Approximate Weights

VALVE

SIZE,

NPS

PRESSURE

CLASS

END

CONNECTION

TYPE

APPROXIMATE WEIGHT

ED/EWD and ET/EWT

ET-C/EWT-C

Short Neck

(2)

Long Neck

(2)

Short Neck

(2)

Long Neck

(2)

Kg

Lb

Kg

Lb

Kg

Lb

Kg

Lb

12

CL150-300

Flanged

950

2100

1090

2400

982

2170

1122

2470

CL600

Flanged

1270

2800

1410

3100

1302

2870

1442

3170

Buttwelding

1130

2500

1270

2800

1162

2570

1302

2870

14

CL150-300

Flanged

1130

2500

1230

2700

1162

2570

1262

2770

CL600

Flanged

1410

3100

1590

3500

1442

3170

1622

3570

Buttwelding

1180

2600

1360

3000

1212

2670

1392

3070

16x12

CL150-300

Flanged

1320

2900

1450

3200

1352

2970

1482

3270

CL600

Flanged

1680

3700

1810

4000

1712

3770

1842

4070

Buttwelding

1410

3100

1540

3400

1442

3170

1572

3470

16

CL150-300

Flanged

1720

3800

2040

4500

1752

3870

2072

4570

CL600

Flanged

2310

5100

2590

5700

2342

5170

2622

5770

Buttwelding

2090

4600

2360

5200

2122

4670

2392

5270

18

CL150-300

Flanged

2310

5100

2500

5500

2342

5170

2532

5570

CL600

Flanged

2900

6400

3130

6900

2932

6470

3162

6970

Buttwelding

2540

5600

2770

6100

2572

5670

2802

6170

20x16

CL150-300

Flanged

2500

5500

2680

5900

2532

5570

2712

5970

CL600

Flanged

3180

7000

3360

7400

3212

7070

3392

7470

Buttwelding

2770

6100

2990

6600

2802

6170

3022

6670

24x16

CL150-300

Flanged

3360

7400

3810

8400

3392

7470

3842

8470

CL600

Flanged

4260

9400

4810

10600

4292

9470

4842

10670

Buttwelding

3770

8300

4220

9300

3802

8370

4252

9370

20

CL150-300

Flanged

4122

9088

4526

9978

(1)

(1)

(1)

(1)

600

Flanged

4736

10442

5112

11269

(1)

(1)

(1)

(1)

Buttwelding

4583

10104

4808

10600

(1)

(1)

(1)

(1)

24x20

CL150-300

Flanged

5507

12140

5856

12910

(1)

(1)

(1)

(1)

600

Flanged

6796

14982

7172

15811

(1)

(1)

(1)

(1)

Buttwelding

6327

13949

6549

14437

(1)

(1)

(1)

(1)

30

CL150-300

Flanged

7390

16300

8350

18400

7535

16620

18545

18720

CL600

Flanged

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Buttwelding

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

1. Contact your

Emerson sales office

or Local Business Partner for these weights.

2. Dependent on valve travel, refer to product bulletin 51.1:ET/ED (Large) (

D103554X012

) for addition details.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by the sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed the limits given in table 1 or on the appropriate nameplates. To avoid such injury or

damage, provide a relief valve for over-pressure protection as required by government or accepted industry codes and

good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.