3

EN-DFA Series

North America

Only

The EN-DFA Series is designed with flanged connections,

and the arrestor provides the option of the removal of the

flame cell element for easy cleaning and replacement

without disconnecting of the pipe connection.

Principle of Operation

Detonation flame arrestor prevents flame propagation

as it enters the exposed side of the unit to the

protected side by absorbing and dissipating heat

using spiral wound crimped ribbon flame cells.

This detonation flame arrestor utilizes a patented

element assembly that dampens the high velocities

and pressures associated with deflagrations and

detonations while quenching the flame front. These

cells allow maximum flow with maximum protection.

Detonation flame arrestor has the heat capacity

and structural design to withstand all the dynamic

conditions of flame propagation and still stop the

flame. Detonation flame arrestor is used when the

flame can be in any of the detonation states.

Limits for Use

The operational temperature, T

0

, shall be limited

as follows:

-4°F ≤ T

0

≤ 140°F / -20°C ≤ T

0

≤ 60°C

The operation pressure, p

0

, shall be limited as follows:

See Table 5

Flame arrestor use shall be limited to gas-air mixtures

with an Maximum Experimental Safe Gap (MESG)

equal to or greater than that tested.

Additional Protection Measures: Flame arrestors

may be used with additional protection measures.

The overall safety of the combined installation shall

be accessed, taking account of any hazardous area

classification (zones) and the likelihood of additional

ignition sources.

Factors Affecting Flame

Arrestor Performance

Gas Group

The type of gas in the system determines its gas

grouping and therefore predetermines the type of

arrestor element required. The element must be

designed to accommodate the specific gas group that

could possibly ignite and propagate in the system.

The more explosive gases require the flame cell to

absorb the heat more quickly and efficiently. The

International Electrotechnical Commission (IEC)

groups gases and vapors into Groups IIA through IIC

categories depending on a number of factors including

the MESG of the gas.

Figure 3.

EN-DFA Series Detonation Flame Arrestor Available Constructions and Model Numbering System

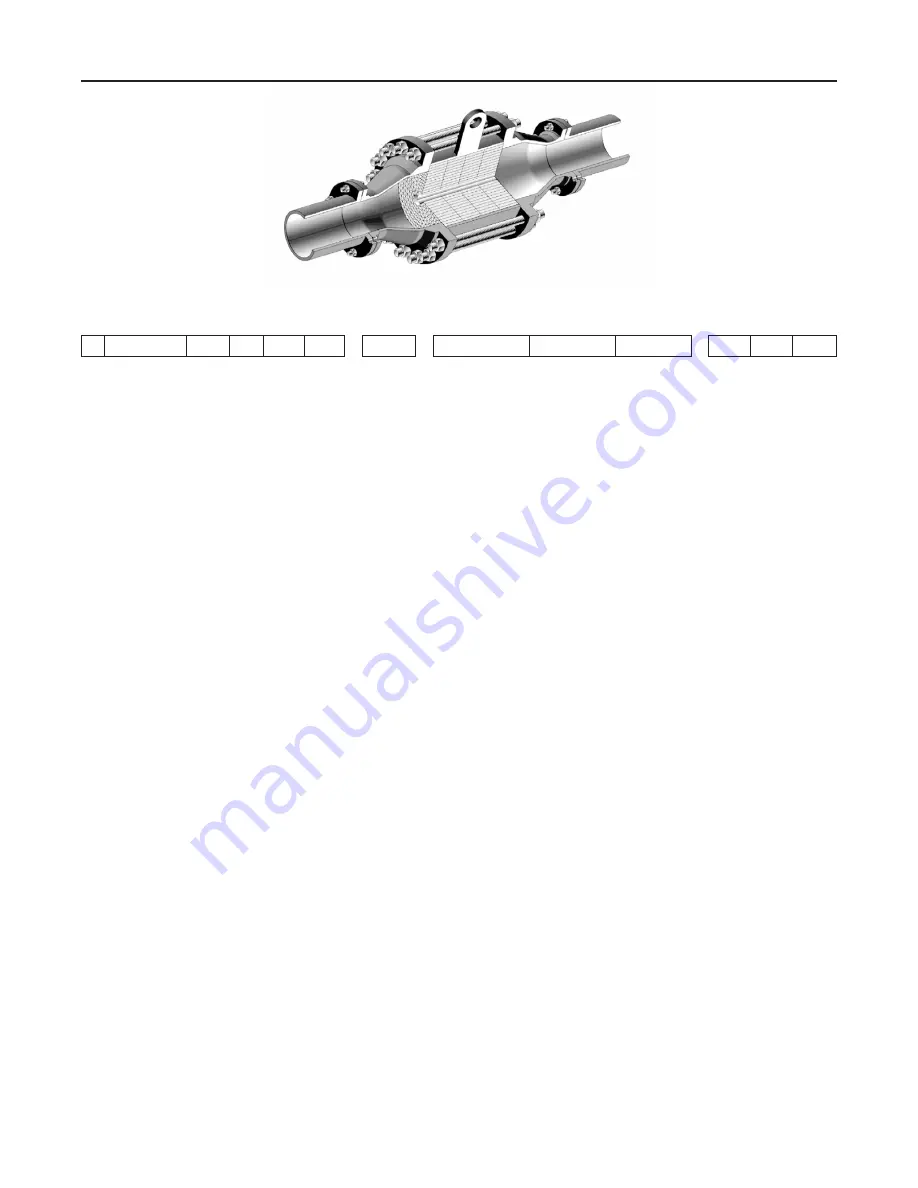

Figure 2.

Cut-away view of EN-DFA Series Detonation Flame Arrestor

EN

DFA

/

-

-

Detonation

Flame

Arrestor

Housing

Size

Connection

Size

IEC

Gas

Group

Housing

Material

Element

Material

Connection

Type

Options

(Concentric)

04 = 4 in.

through

26 = 26 in.

02 = 2 in.

through

12 = 12 in.

IIA (D)

IIB3 (C)

C = Carbon Steel

4 = 304 SST

6 = 316 SST

H = Hastelloy

®

4 = 304 SST

6 = 316 SST

H = Hastelloy

®

F = Flat face

flange

R = Raised

face

flange

1 = Drain Plug

2 = Pressure Tap

3 = Temperature Probe

Tap

(standard)

4 = Miscellaneous

5 = Protective coating

6 = Special feature

Hastelloy

®

C is a mark owned by Haynes International, Inc.