C6.2.7/1007-0619/E

15

4.4 Pressure safety controls

4.4.1 High-pressure protection

The cut-out setting for the high-pressure control shall be determined according to regional standards,

usually EN 378, part 2 in Europe.

The maximum pressure value for the individual compressor type, PS high side, is printed on the

nameplate of the compressor.

The high-pressure cut-out should have a manual reset feature for the highest level of system

protection.

4.4.2 Low-pressure protection

IMPORTANT

Loss of system charge and lubrication! Bearing malfunction!

Compressor breakdown!

A low-pressure control is highly recommended. Do

not bridge or by-pass the low-pressure cut out.

The minimum cut-out setting shall be determined according to the refrigerant and to the allowed

operation envelope

– see technical data in Select software at

. For

example, a minimum cut-out setting of 1.0 bar(g) is required for ZRH* and ZBH* compressors using

R407C.

The low-pressure cut-out should have a manual reset feature for the highest level of system

protection.

4.4.3 Internal pressure relief valve

ZRH(V)* and ZBH(V)* horizontal compressors do NOT have any internal pressure relief valve. To

ensure safe operation, a high-pressure control must be used in all applications.

4.5 Discharge gas temperature protection

IMPORTANT

Inadequate lubrication! Scroll set damage!

All ZRH* and ZBH* horizontal

Scroll compressors must be equipped with an external discharge gas

temperature protection.

Internal discharge temperatures can reach unacceptable values under some extreme operating

conditions (such as loss of refrigerant injection charge or extremely high compression ratio). This

could cause compressor damage.

The discharge thermostat dedicated to ZRH* and ZBH* horizontal Scroll compressors has a cut-out

setting of 105°C ± 4K with closing at 88°C ± 8K. It should be installed approximately 120 mm from

the discharge valve outlet (see assembly instructions below).

To ensure proper functioning and to avoid false readings, the discharge line thermostat must be

installed and insulated according to the procedure and recommendations hereunder.

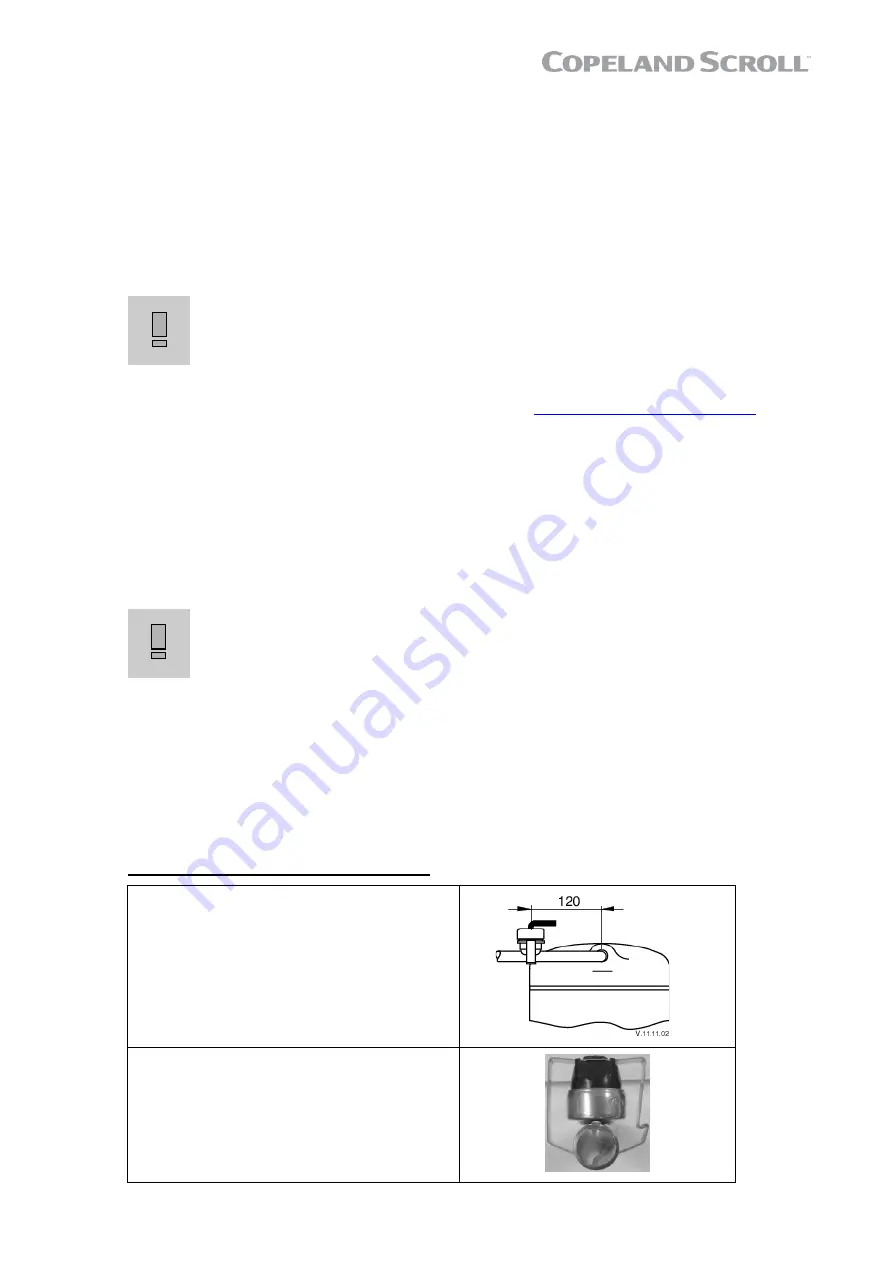

Assembly of the discharge line thermostat

▪

Install the discharge line thermostat on the

discharge tube 120 mm from top cap.

▪

Snap the retainer clip over the tube and onto

the thermostat.

▪

The thermostat should be placed on the

discharge tube so that its body is in upward

position on a horizontal tube installation.

▪

Ensure that the thermostat is not tilted.