651 - 652 - 653

q

ATEX

USABLE IN ATEX ZONES

1/8-1/4 (651) 1/4-3/8-1/2 (652) 1/2-3/4-1 (653)

539526-001 / AA

A

vailability

, design and specifications are subject to change without notice

. All r

ights reser

ved.

B

1

2

3

fig. A

3

516025-001

EN

NON-ATEX VERSIONS

652 SERIES

USABLE IN ATEX ZONES

q

This product category does not require certification. There is no potential ignition risk to the products themselves.

These product categories are named simple mechanical products and do not include moving parts. These products

can be used in specific explosion zones 1 and 21 in compliance with our installation instructions:

• Mounting components

• Assembly and connection components

• Mechanical accessories

• Filter and coalescing filter

• Lubricator

• Diverter block

• Shut-off valve

These conditioning units of compressed air and their accessories

are envisaged for use in explosive atmos-

pheres in the form of gas, steam, mists and dust.

______________________________________________________________________________________________

!

SPECIAL CONDITIONS FOR SAFE “X” USAGE :

Risk from electrostatic charges

Prevent electrostatic charging of external insulating surfaces by using the appropriate installation and cleaning

measures. To clean external insulating surfaces use a damp cloth.

Connect the conditioning units to the earth.

When combined with other conditioning units, ensure that all metallic and conductive parts are always intercon-

nected and linked to the earth to avoid significant electrostatic charges being created.

The earth is connected to the unit or to the combination of conditioning units by the downstream and upstream

use of metal pipes connected to the earth. If the pipes are non-conductive, earth connection should be performed

by the assembly and/or fixing devices adapted to the ATEX products.

______________________________________________________________________________________________

Installation, commissioning and servicing and maintenance

These operations may only be carried out by authorised personnel and in accordance with the usage instructions.

Only carry out maintenance in zones where there is no explosive atmosphere.

If during maintenance it is established that wearing and spare parts need exchanging, contact an ASCO

Numatics reseller.

Any modification of the product with parts not supplied by the manufacturer will invalidate the certification.

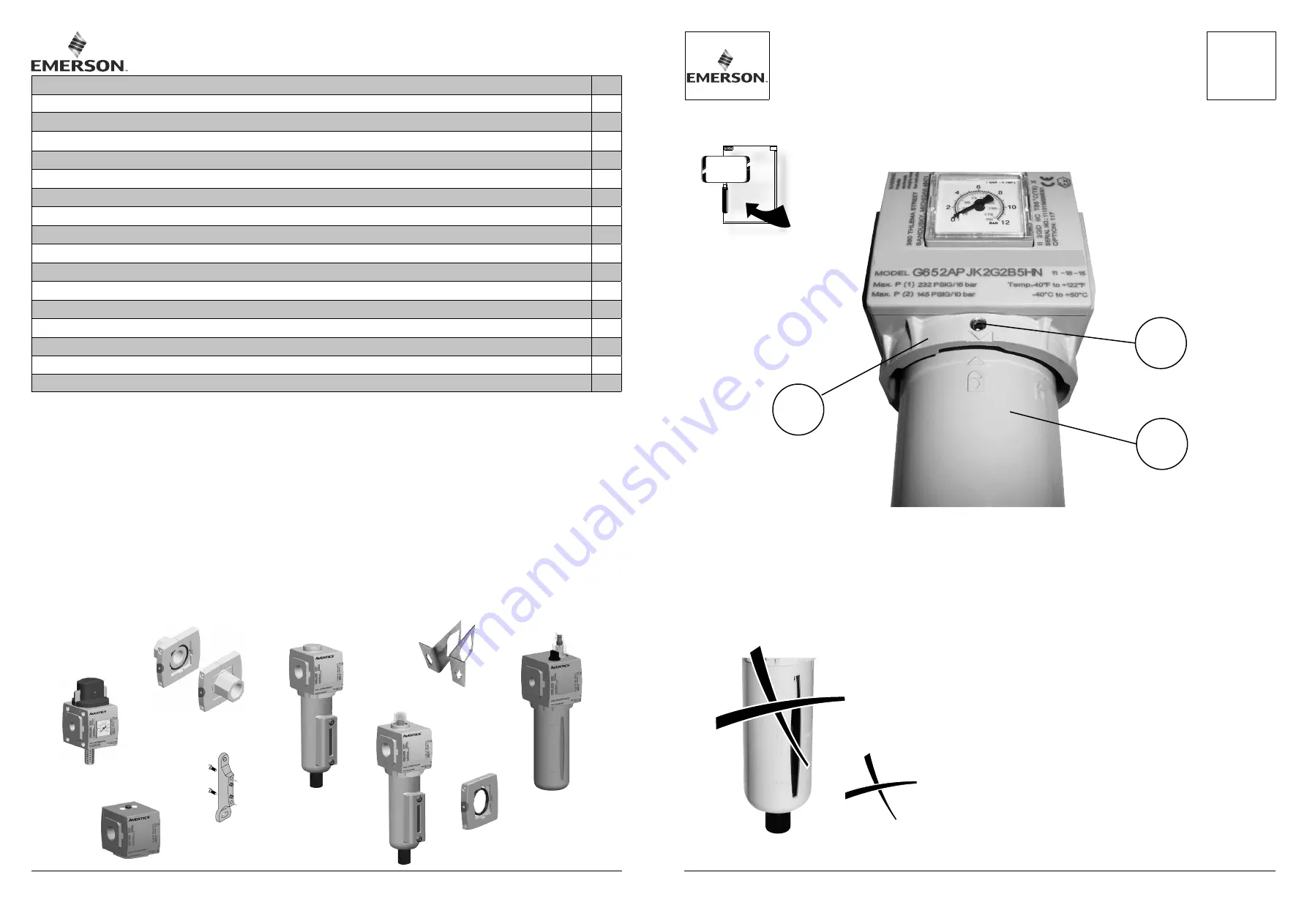

Filtre et Lubrificateur équipés de cuve métallique : (Voir fig. A)

Lors d’un remplacement d’élément filtrant saturé du Filtre, procéder comme décrit ci-dessous :

• Dévisser la vis (1)

• Enlever la cuve (2) du corps (3)

• Retirer l’élément filtrant et le remplacer par un neuf

• Remettre la cuve (2) en place

• Revisser la vis (1) dans le corps (3) jusqu’au contact de la cuve et effectuer ¼ à ½ tour supplémentaire pour

assurer la continuité de masse.

Pour ajouter de l’huile dans la cuve du Lubrificateur, procéder de la même façon que ci-dessus

4..20

metal

polycarbonate

AVENTICS SERIES 651-652-653

651 - 652 - 653

▼ ▼

q

3

Visit our website at www.emerson.com/aventics

2

Visit our website at www.emerson.com/aventics

AVENTICS - INSTALLATION AND MAINTENANCE INSTRUCTIONS

EN

AVENTICS - INSTRUCTIONS D’INSTALLATION ET DE MAINTENANCE

FR

AVENTICS - INBETRIEBNAHME - UND WARTUNGSANLEITUNG

DE

AVENTICS - INSTRUCCIONES DE PUESTA EN MARCHA Y MANTENIMIENTO

ES

AVENTICS - INSTRUZIONI DI MESSA IN SERVIZIO E MANUTENZIONE

IT

AVENTICS - ALGEMENE INSTALLATIE- EN ONDERHOUDSINSTRUCTIES

NL

AVENTICS - INSTALLASJONS- OG VEDLIKEHOLDSINSTRUKSER

NO

AVENTICS - INSTALLATIONS- OCH UNDERHÅLLSINSTRUKTIONER

SE

AVENTICS - ASENNUS - JA HUOLTO-OHJEET

FI

AVENTICS - INSTALLATIONS - OG VEDLIGEHOLDSANVISNINGER

DK

AVENTICS - INSTRUÇÕES DE INSTALAÇÃO E MANUTENÇÃO

PT

AVENTICS -

ΟΔΗΓΙΕΣ

ΤΟΠΟΘΕΤΗΣΗΣ ΚΑΙ ΣΥΝΤΗΡΗΣΗΣ

GR

AVENTICS -

POKYNY PRO INSTALACI A ÚDRŽBU

CZ

AVENTICS -

INSTRUKCJA MONTAŻU I KONSERWACJI

PL

AVENTICS -

TELEPÍTÉSI ÉS KARBANTARTÁSI ÚTMUTATÓ

HU

AVENTICS -

ИНСТРУКЦИЯ ПО УСТАНОВКЕ И ОБСЛУЖИВАНИЮ

RU

AVENTICS -

ОРНАТУ ЖӘНЕ ҚЫЗМЕТ КӨРСЕТУ НҰСҚАУЛАР

KZ

539526-001