SECTION 3 BYPASSING & ISOLATING

3--1

BYPASSING

This procedure explains how to Bypass the closed

Automatic Transfer Switch contacts. Bypassing is re-

quired before the ATS can be tested or isolated. The

Bypass Switch must be in the

AUTOMATIC POS

(posi-

tion) and the Isolation Handle must be in the connected

position (turned clockwise until it stops). The

CON-

NECTED

light should be on.

1. Observe which Automatic Transfer Switch

CLOSED

ON

light is on (

NORMAL

or

EMERGENCY)

on the

STATUS INDICATOR panel. This light indicates the

source connected to the load.

2. Bypass to the

same

source connected to the load as

follows (select direction). See Figure 3-1, Figure 3-2,

and Figure 3-3.

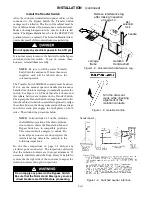

Figure 3-1. Bypass Handle.

To Bypass Normal Source

Push in

the Bypass

Handle then turn it

counterclockwise

to

BYPASS POS

. The By-

pass Switch

CLOSED

ON NORMAL

light

should come on. *

Figure 3-2. Bypass to Normal.

To Bypass Emergency Source

Figure 3-3. Bypass to Emergency.

Pull out

the Bypass

Handle then turn it

counterclockwise

to

BYPASS POS

. The By-

pass Switch

CLOSED

ON

EMERGENCY

light should come on. *

The Automatic Transfer Switch can now be put in the

TEST

or

OPEN

position. See

ISOLATING

.

* NOTE

: When Acc. 66A is specified, the

handle operation is reversed.

Follow

instruction on the door.

ISOLATING

This procedure explains how to isolate the Automatic

Transfer Switch. Isolating is required before any service

work can be performed on the ATS. Observe the ATS

POSITION lights on the STATUS INDICATOR panel.

1. Bypass the closed Automatic Transfer Switch

contacts. See

BYPASSING

.

2. Isolate the Automatic Transfer Switch as follows.

Refer to Figure 3-4 and Figure 3-5.

Isolation Handle

installed through

enclosure door

Figure 3-4. Isolation Handle.

Bypass–Isolation Switch is energized.

Do not touch isolation contact fingers;

shock, burns, or death could result.

To Isolate the Automatic Transfer Switch

a. Open the enclosure door and remove the

Isolation

Handle

stored on the right side of the carriage

frame. Close the door. Insert the Isolation Handle

into the shaft (through the door).

b. Turn

Isolation Handle

counterclockwise (about 6

or 7 turns) until the

TEST

light comes on.

c. Continue turning

Isolation Handle

counterclock-

wise (approximately 10 or 11 turns) until it stops

and

DISCONNECTED

light comes on,

TEST

light off.

d. Remove

Isolation Handle

and store it inside the

enclosure on the right side of the carriage frame.

Figure 3-5. Isolated (DISCONNECTED) ATS.

The Transfer Switch can now be removed for inspection

and maintenance. See page 3–2.