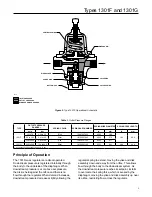

Types 1301F and 1301G

5

Maintenance

Regulator parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency

of inspection and parts replacement depends on the

severity of service conditions and the requirements of

local, state and federal rules and regulations.

Instructions are given below for disassembly and

assembly of parts.

!

WARNING

To avoid personal injury or equipment

damage from sudden release of pressure

or explosion of accumulated gas, do not

attempt any maintenance or disassembly

without first isolating the regulator from

system pressure and relieving all internal

pressure from the regulator.

Disassembly

The following procedure describes how to completely

disassemble the regulator. When part replacement

or inspection is required, complete only those steps

necessary to accomplish the job. Key numbers

referenced are shown in Figure 3 for the Type 1301F

regulator and in Figure 4 for the Type 1301G regulator

unless otherwise indicated.

1.

Loosen the locknut (key 18).

2.

Turn the adjusting screw (key 15)

counterclockwise to remove spring compression.

3.

Remove the bottom cap (key 3), bottom cap

O-ring (key 14) and spring (key 10).

4.

Unthread the valve disk assembly (key 6) from

the yoke (key 4).

5.

Remove the valve disk collar (key 22) from the

valve disk assembly.

6.

Remove the spring case cap screws (key 16),

and separate the spring case (key 2) from the

body (key 1).

7. Remove the upper spring seat and spring

(keys 9 and 11).

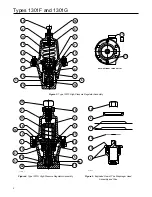

8. Refer to Figure 5. Unscrew the diaphragm

locknut (key 19), and remove the diaphragm

plate (key 8), the two diaphragms (key 7) and the

diaphragm plate gasket (key 13).

9.

Remove the screws (key 17) from the yoke, and

take the lower and upper halves of the yoke out

of the body. The yoke halves are a matched set

and need to be kept together.

10.

Unscrew the orifice (key 5). Examine seating

edge of orifice. Replace with a new part if worn

or nicked.

Assembly

This procedure assumes that the regulator was

completely disassembled. If not, start these

instructions at the appropriate step. Key numbers used

are shown in Figure 3 for the Type 1301F regulator

and in Figure 4 for the Type 1301G regulator unless

otherwise indicated.

1.

Screw the orifice (key 5) into the regulator.

2.

Insert both halves of the yoke (key 4) into the

regulator, and fasten them together with the

screws (key 17). The yoke halves are a matched

set and need to be kept together.

3.

The valve disk assembly (key 6) has two valve

disks, one on each end. Inspect both valve disks,

and select the one to be used. Thread the valve

disk assembly into the yoke so that the disk to be

used is positioned against the orifice. Thread the

valve disk collar (key 22) onto the exposed end of

the valve disk assembly.

4.

Place the bottom cap O-ring (key 14) on the

bottom cap (key 3). Place the spring (key 10) in

the bottom cap, and thread it into the regulator.

5.

Put the body gasket (key 12) on the regulator

body (key 1).

6. Refer to Figure 5. Place the diaphragm plate

gasket (key 13), two diaphragms (key 7), and

the diaphragm plate (key 8) on the yoke (key 4).

Make sure the diaphragm convolutions are toward

the spring, and secure the parts by threading the

diaphragm locknut (key 19) onto the yoke.

7.

Place the regulator spring (key 11) and upper

spring seat (key 9) on the diaphragm plate.

8.

Position the spring case (key 2) over the spring and

on the regulator body. Orient the spring case vent or

vents as necessary. Insert the cap screws (key 16),

and tighten them only finger-tight.

9.

Thread the adjusting screw and locknut (keys 15

and 18) into the spring case just far enough to

slightly compress the spring. Securely tighten the

cap screws (key 16), and refer to the Startup section

for adjustment procedures.