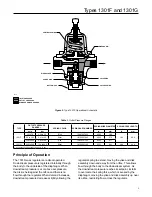

Types 1301F and 1301G

4

Installation

!

WARNING

Overpressuring a regulator or

associated equipment may cause

leakage, part damage or personal injury

due to bursting of pressure containing

parts or explosion of accumulated gas.

Do not install a regulator where service

conditions can exceed the specifications

listed on the Specifications section, or

any applicable local, state or federal

codes and regulations.

Use qualified personnel when installing, operating and

maintaining these regulators. Make sure that there

is no damage or foreign material in the regulator and

that all tubing and piping are clean and unobstructed.

The regulator may be installed in any position. Apply

pipe compound to the pipeline threads. Connect inlet

piping or tubing to the 1/4 NPT connection marked

“In” and outlet piping or tubing to one of the 1/4 NPT

connections marked “Out”. Install a pressure gauge or

pipe plug in the unused outlet connections.

If continuous operation of the system is required

during inspection or maintenance, install a three-valve

bypass around the regulator.

!

WARNING

A regulator may vent some gas to

the atmosphere. In hazardous gas

service, vented gas may accumulate,

causing personal injury or equipment

damage due to fire or explosion. Vent

a regulator in hazardous gas service to

a remote, safe location.

The optional stainless steel spring case of the

Type 1301F regulator has one 1/4 NPT internal

connection. The Type 1301G regulator spring case

has one 1/8 NPT internal connection with a screen. To

remotely vent the spring case, remove the screen, if

present, and connect 1/4 or 1/8 NPT piping or tubing

to the spring case connection. The piping or tubing

should vent the spring case to a safe location, have as

few bends as possible, and have a screened vent on its

exhaust end.

Each regulator is factory-set for the pressure setting

specified on the order. If no setting is specified, outlet

pressure is factory-set at the midpoint of the regulator

spring range. If pressure adjustment is necessary, refer

to the Startup section. In all cases, check the spring

setting to make sure it is correct for the application.

Overpressure Protection

The 1301 Series regulators have an outlet pressure

rating lower than their inlet pressure rating. If actual

inlet pressure can exceed the outlet pressure rating,

outlet overpressure protection is necessary. However,

overpressuring any portion of the regulators beyond

the limits in Specifications section may cause leakage,

damage to regulator parts or personal injury due to

bursting of pressure-containing parts.

Some type of external overpressure protection should be

provided if inlet pressure will be high enough to damage

downstream equipment. Common methods of external

overpressure protection include relief valves, monitoring

regulators, shutoff devices and series regulation.

If the regulator is exposed to an overpressure

condition, it should be inspected for any damage that

may have occurred. Regulator operation below these

limits does not preclude the possibility of damage from

external sources or from debris in the pipeline.

Startup

With installation completed and downstream

equipment adjusted, slowly open the upstream and

downstream block valves while using pressure gauges

to monitor pressure.

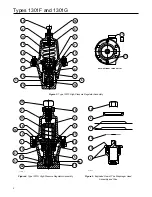

If adjustment is necessary, loosen the locknut

(key 18, Figures 3 and 4), and turn the adjusting

screw (key 15, Figures 3 and 4) clockwise to

increase the set pressure or counterclockwise to

decrease the set pressure. Monitor pressure with

gauges during adjustment. When adjustment is

complete, tighten the locknut. If the desired outlet

pressure is not within the range of the regulator

spring, install a spring with a desired range

according to the Maintenance section.

Shutdown

First, close the upstream shutoff valve, and then,

close the downstream shutoff valve. Next, open

the vent valve between the regulator and the

downstream shutoff valve and open the vent valve

between the regulator and the upstream shutoff

valve. If vent valves are not installed, safely bleed

off both inlet and outlet pressures and check that

the regulator contains no pressure.