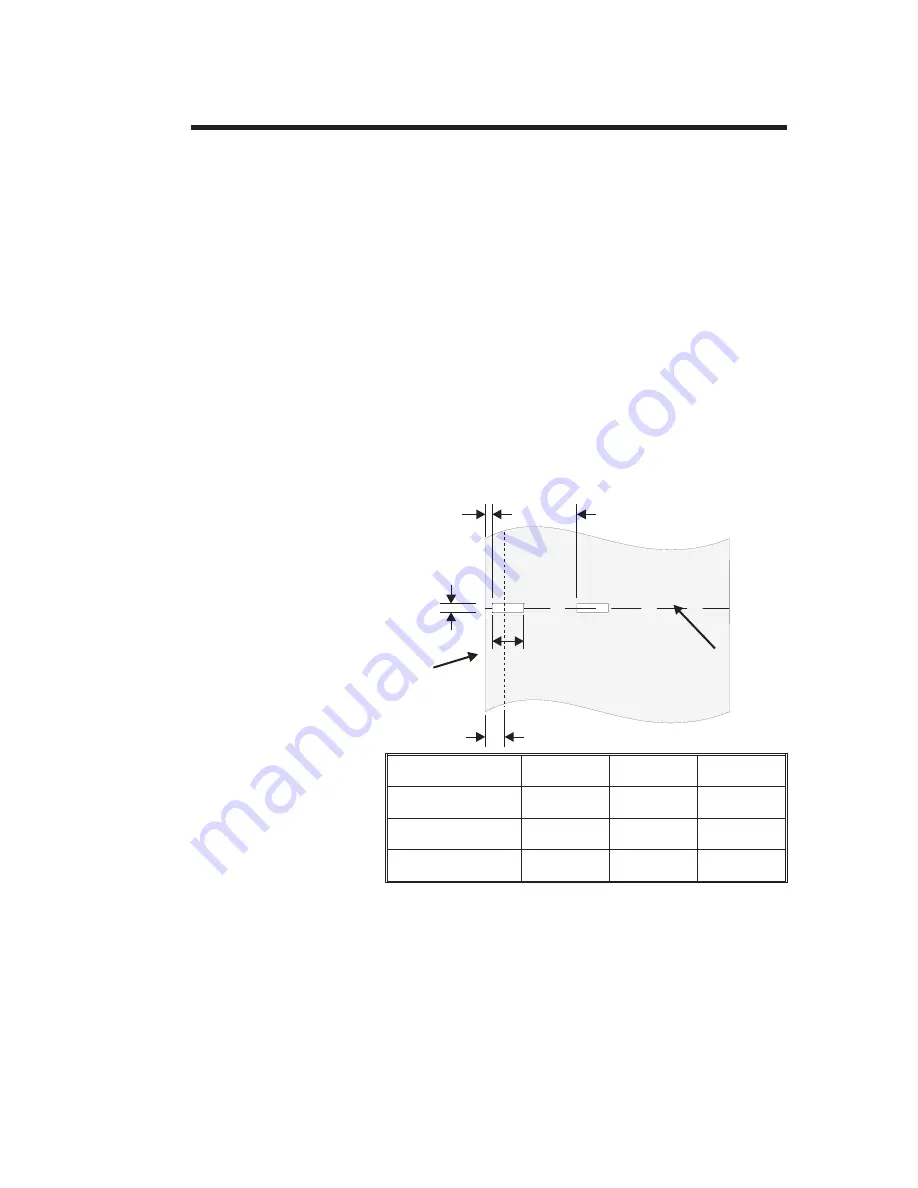

Printer Tag

Sense Through

Hole Position

The TLP 2046 printer uses a moveable sensor

to detect index holes/notches in tag stock. The

sensor position is indicated by the green arrow

at the front of the label guide that is visible with

the printhead open. The sensor can be moved

by squeezing the two locking tabs, located

under the label guide, and sliding the sensor in

or out. For proper sensing, ensure that the

sensor is aligned with the center portion of the

index hole/notch.

The following dimensions show the required

position of the Sense-Through (“Notch”) hole

on tag stock for the TLP2046 printer.

Dimension

Min.

Max.

Nominal

A

.236"

None

.512"

B

.079"

.512"

.118"

C

.098"

.216"

N/A

B

C

A

.314 Nominal Sensor Location

min.

max.

Inside Edge

of Tag Stock

Tag

Tear-away

Figure C-2

Tag Position

Sensing Layout

Trouble Shooting

980003-003 Rev. A

47

Summary of Contents for TLP2044

Page 1: ...User s Manual No 980003 003 Rev A 1996 Eltron International Inc TLP2046 User s Manual ...

Page 2: ......

Page 6: ...vi 980003 003 Rev A ...

Page 48: ...Operation 42 980003 003 Rev A ...

Page 62: ...Accessories 56 980003 003 Rev A ...

Page 66: ...Windows Printer Driver 60 980003 003 Rev A ...

Page 67: ...Windows Printer Driver 980003 003 Rev A 61 ...

Page 68: ...41 Moreland Road Simi Valley CA 93065 805 579 1800 FAX 805 579 1808 ...