Page 3

1000004301 (Rev. D - 07/19)

LZS8WS_2FWR, LZWSR_2CWR

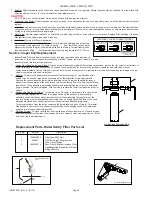

Figure 1

Installation: Bottle Filler Mounting

Figure 2

Figure 3

Figure 4

F

E

A

B

7/

1

6

" X 3

/

4"

O

BR

O

UND

(11mm X 1

9

mm) H

O

LES (

6

)

C

D

E

9/

32"

O

H

O

LES

(

7

mm) (12)

FINISHED FL

OO

R

L

C

7

"

1

7

8mm

7

"

1

7

8mm

1

7

7/

8"

454mm

6

3

/

8"

1

6

2mm

6

3

/

8"

1

6

2mm

2"

51mm

2"

51mm

5 3

/

4"

14

6

mm

13 15

/

1

6

"

354mm

1

7

7/

1

6

"

443mm

1

9

"

483mm

28 13

/

1

6

"

7

32mm

51

9/

1

6

"

1310mm

18

7/

8"

4

79

mm

12 1

/

2"

318mm

31 5

/

1

6

"

796

mm

RI

M

HEI

G

HT

32

7/

8"

835mm

O

RIFICE

HEI

G

HT

21

7/

8"

55

6

mm

2"

51mm

3

7/

8"

9

8mm

7

"

1

7

8mm

7

"

1

7

8mm

28 13

/

1

6

"

7

32mm

2"

51mm

2

7/

8"

7

3mm

15"

381mm

2

7

"

6

8

6

mm

ADA

REQUIRE

M

ENT

8 1

/

1

6

"

205mm

1

9

"

483mm

3

9/

1

6

"

9

0mm

5

7/

8"

150mm

3"

77

mm

2"

51mm

38 1

/

2"

979

mm

ACTIVATI

O

N

SENS

O

R

HAN

G

ER BRACKET

Rough-In: LZS8WSS2KWR

7/16” BOLT HOLES FOR

FASTENING UNIT TO WALL

UNIT CENTER LINE

TOP COVER

MOUNTING

SCREWS

29

1.

Remove two (2) mounting screws with 5/32” Allen wrench holding

top cover to Bottle Filler (see Fig 3). Remove top cover. Note: do not

discard mounting screws; they will be needed to reinstall top cover.

2. Remove wall mounting plate from Bottle Filler. Place wall plate

against wall on top of basin. Center the wall plate side to side with

the basin. Mark the six (6) mounting holes with a pencil (See Fig 1).

3.

Remove wall mounting plate from wall. NOTE: Mounting plate

MUST be supported securely. Add fixture support carrier if wall

will not provide adequate support.

4.

Install wall mounting plate to wall using six (6) 7/16” oval mounting

holes (mounting bolts not included) (See Fig 2). Use appropriate

fasteners for your wall type.

5.

Feed 3/8” water line through hole in tower/basin gasket (See Fig 4).

6. Install gasket on bottom of bottle filler tower with gasket support

bracket & (2) screws (See Fig 5).

7.

Feed modular (C-13) end of International Power Cord Set up

through basin hole and hole in gasket, and connect to Power Inlet

on Bottle Filler. Do not plug into electrical outlet.

8.

Lay Bottle Filler on water cooler basin and cut insulation from tube

even with bottom of gasket, remove this insulation from the 3/8”

tube, but do not discard. Feed the waterline through the hole on

top of water cooler. NOTE: To prevent scratching the basin, place

a towel or soft cloth over the entire basin when working above it.

Figure 5

Bracket & Screws

A = Water Mains Supply, 3/8” (9.5mm) O.D. compression outlet of Shut-off Valve (not provided) to be 3” (76mm) from Wall.

B = Waste Outlet, 1-1/4” (31.8mm) O.D. Drain tube terminating 2” (51mm) maximum from wall.

C = 1-1/4” (31.8mm) Trap (not provided).

D = Electrical Mains Supply Outlet, 3-wire in Recessed Box. Must have Ground Fault Circuit Interrupter (GFCI) protection.

E = Ensure proper ventilation by maintaining 6” (152mm) minimum clearance from cabinet louvers to wall.

F = 7/16” (11mm) Bolt holes for fastening unit to wall.