5

List of Materials

Parts supplied

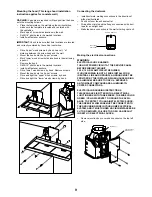

Removing the packaging

CAUTION!

Remove carton carefully, Wear gloves to protect against

sharp edges.

WARNING!

Remove the protective film covering the product before

putting into operation.

Hood structure assembly with blower, transition.

Lamp already installed.

2 Grease filters 30” or 3 Grease filters 36”.

Duct cover.

Hardware bag with:

Template

Duct cover support bracket (1 piece)

Use, care and installation guide

Wood screws (6 pieces - 3/16” x 1” 3/4)

Concrete wall anchors (6 pieces - 1/8” x 3/8”)

Assembly screws (4 pieces)

•

•

•

•

•

•

•

•

•

•

Parts not supplied

Optional Accessories

Telescopic duct cover to fit ceiling height from 8’ to 10’

Recirculation KIT

Non return valve

Tools/Materials required

Duct tape

Wire nuts

Masking tape

8” rounded metal duct (lenght to suit installation)

Pliers

Gloves

Knife

Safety glasses

Electric drill with 5/16” and 3/8” Bits

Strain relief

Spirit level

Duct tape

Screwdrivers:

Phillips (Posidrive) # 2

Torx #2

Wire cutter/stripper

Hammer

Saw, jig saw or reciprocating saw

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

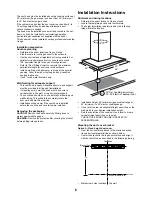

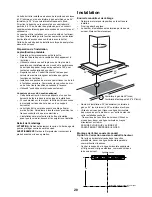

Installation Requirements

Before installing the hood

For the most efficient air flow exhaust, use a straight run

or as few elbows as possible.

CAUTION:

Vent unit to outside of building only.

At least two people are needed for installation.

On average one to three hours are necessary to complete

installation (without considering cut to be done on wall

and/or on cabinet, installation ducts, conduit and electrical

connections to the mains).

The hood is fitted with screws and wall anchors suitable

for most surfaces, consult a qualified installer, check if

they perfectly fit with your cabinet/wall.

Do not use flex ducting.

COLD WEATHER installations should have an additional

non return valve (Accessory not provided with the hood)

installed to minimize backward cold airflow and a thermal

break to minimize conduction of outside temperatures

as part of the duct work. The damper should be on the

cold air side of the thermal break.

Makeup air local building codes may require the use of

makeup air systems when using ducted ventilation

systems greater than specified CFM of air movement.

Consult your HVAC professional for specific requirements

in your area.

•

•

•

•

•

•

•

h

20”

30“

36“

17- 4/16”

28- 25/32”

30” Gas Cooktop (minimum)

24”-30“ Electric Cooktop (min)

h

Product Dimensions & Clearances