18

6.3.2.1 How to determine the Sound Velocity

1. Select a stored sound velocity or set the gauge to a sound velocity as close as possible to

the sound velocity of the material to be measured.

2. Take a sample of a defined thickness as close as possible to the thickness of the later

measuring object. If no such sample is available, take your measuring object and measure

its thickness using a caliper or another measuring tool.

3. Now use MiniTest 430 or 440 to measure the sample in order to get a thickness value.

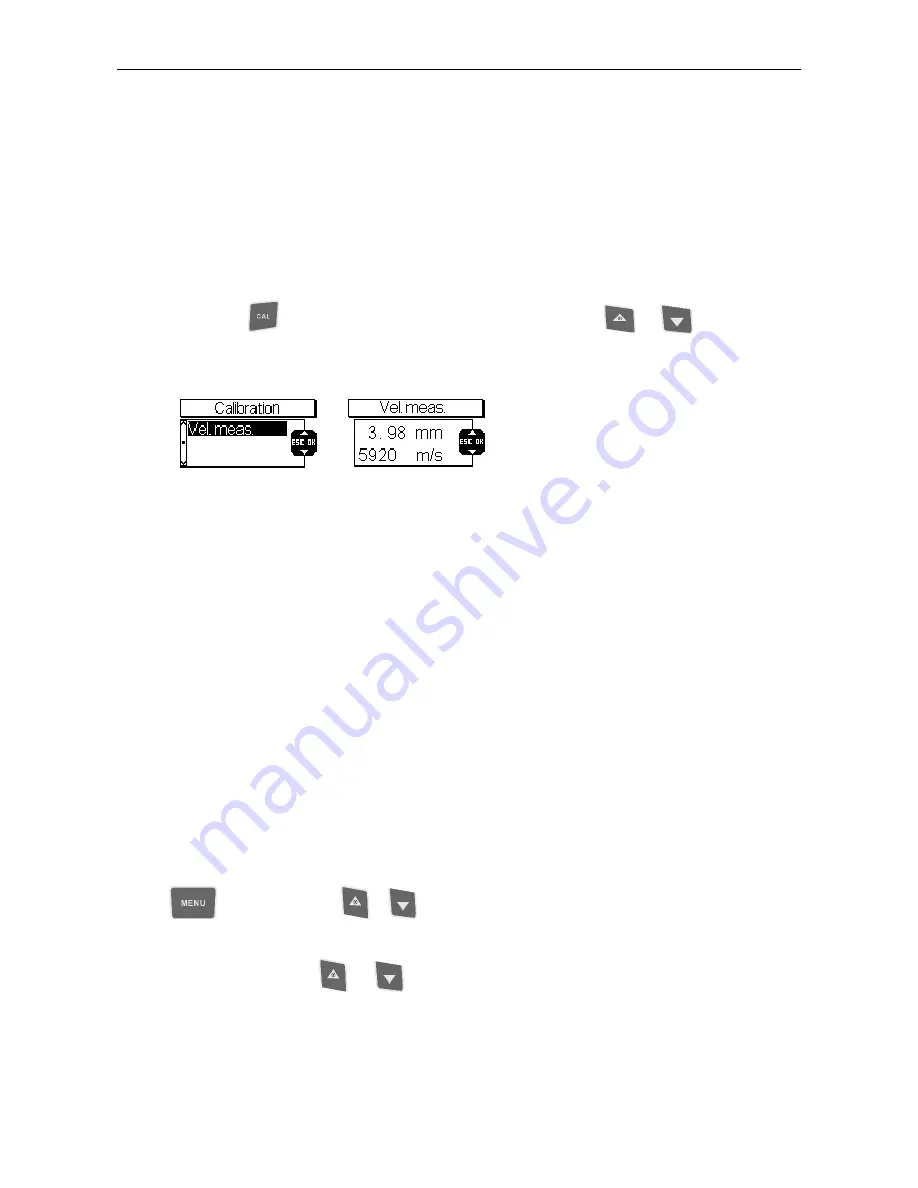

4. First press

-key to go to the “Sound velocity”. Then press

or

in order to

adjust to the thickness reading you have measured and get the correct sound velocity

accordingly.

5. Adjust the sound velocity so that the material thickness shown on display corresponds to

the measured thickness of sample.

6. Re-measure the sample and check the deviation between reading and actual thickness. If

both values are identical, the sound velocity is correct for this material.

6.3.3 Calibration of the Transducer

The transducer calibration function is to be used to compensate for errors or system errors that

cannot be remedied by “Automatic calibration”. The cause of such error might be for instance a

transducer change. First make sure the error is not due the setting of an unsuitable sound velocity.

To carry out the transducer calibration please proceed as follows:

1. Adjust the gauge to the sound velocity 5920 m/s.

2. Take a reading on test block supplied with the gauge and take. The reading obtained

should be 4.00 mm ± 0.01 mm. If the reading obtained differs from that value, press the

-key. Then press

or

. Choose “Transducer calibration“ and press OK to

confirm.

Now use arrow keys

or

to adjust the reading you obtained to the thickness of

test block, i.e. 4.00 mm. Press OK to confirm the value. Then press ESC to go to the

measuring mode.