Key points

• The trays are automatically loaded from a cord

conveyor into the TW1E and - after washing, rinsing

and drying - automatically unloaded on a lowerator,

with a capacity up to100 trays.

• On the unloading side the dishwasher has a tray

buffer for a maximum 10 trays, in order to avoid to

block the operations during the replacement of the

trolley.

• As optional, a two-lowerators station is available.

This accessory allows to increase the tray buffer

capacity of one lowerator (up to 100 trays), giving

more time to the user, to replace the full lowerator.

• Washing and rinsing systems are designed to gua-

rantee high efficiency and performances.

• The high-pressure ventilator that blows air very

close to the trays and the inclined designed that

helps the water drain off the trays, guarantees an

efficient drying function.

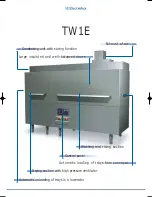

TW1E

Electrolux can offer tailored solutions for creating an automatic

dishwashing system, combining Electrolux dishwashers with a pro-

per handling system equipment, such as tray conveyors, sorting and

stacking stations, cutlery removing device and napkin blower devi-

ce. The new Electrolux tray washer for automatic washing of trays

is one of the key functions in an automatic dishwashing system,

suitable to treat cookeries in canteens with up to 1200 guest per

hour. The new tray washer can guarantee the best working condi-

tions - lower noise and heat emission - thanks to the double skin

and insulated construction and to the condensing unit (standard

accessory in all models)

The internal components - washing and rinsing arms, filters, tank

rounded corners and sloping base - allow a better cleanability;

while the large and well-balanced doors give the proper accessibi-

lity for cleaning and maintenance.

The frame and the main components are made of AISI 304, while

the tank is made of acid proof stainless steel (AISI 316) for a relia-

ble and long lasting performance.

tray washer/eng 22-02-2005 12:17 Pagina 4

Summary of Contents for TW1E

Page 1: ...Tray Washer ...